Glass simulating sponge support and preparing method thereof

A technology of sponge and glass, which is applied in the field of medical stents, can solve the problems of limited applicability of Ni-Ti shape memory alloy stents, the size of the diseased part changes the size of the structure itself, and so on, so as to save treatment costs, relieve obstruction, and avoid extrusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

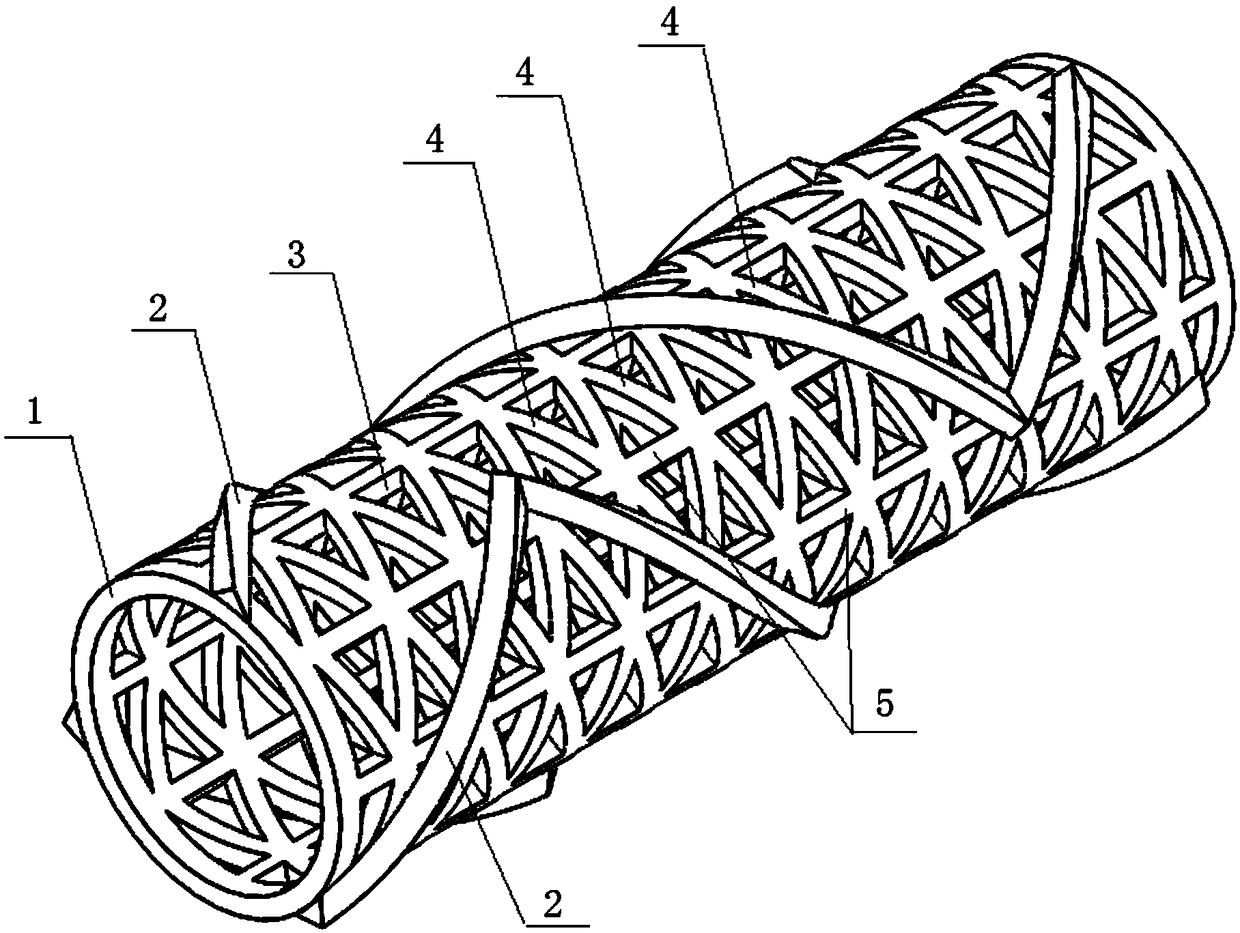

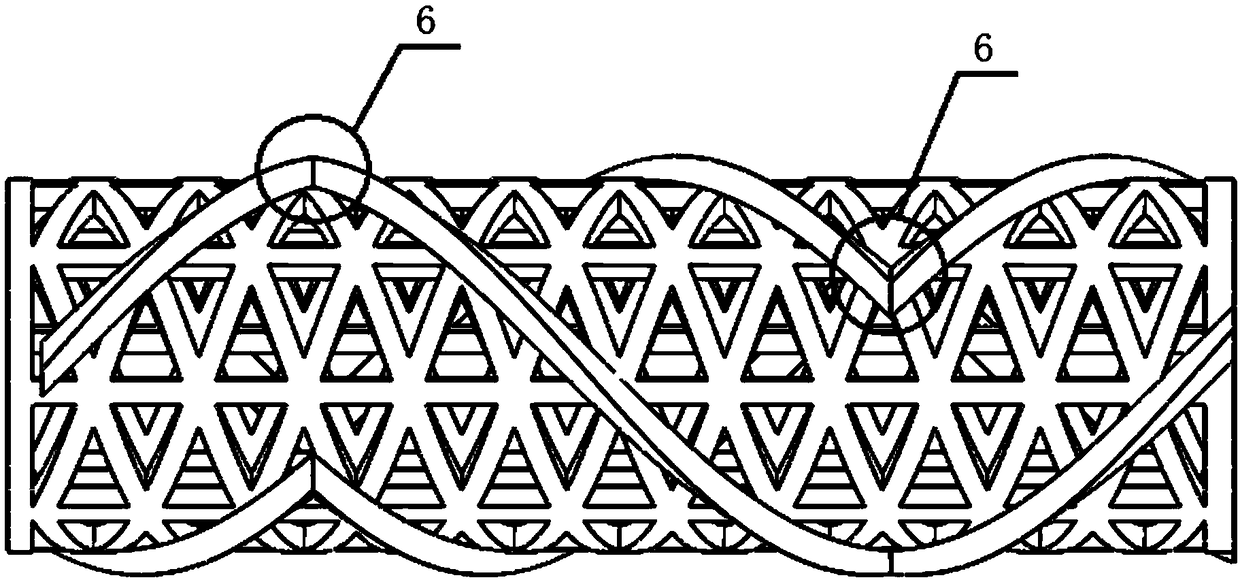

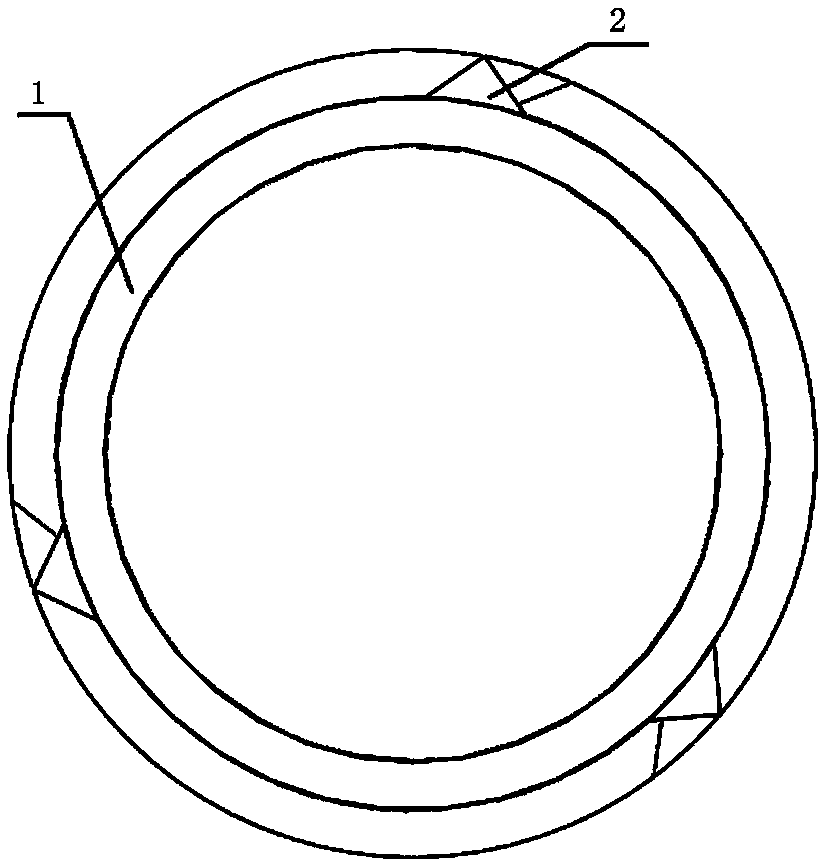

[0039] Specific implementation mode one: combine Figure 1 to Figure 9 To describe this embodiment,

[0040] A kind of imitation glass sponge support, including bionic tissue engineering support 1 and ribs 2, described bionic tissue engineering support 1 is composed of a group of axial support meridians 5 and two sets of helically surrounded support base lines 4 with a through-hole The cylindrical wall of the hole 3, and the two groups of bracket baselines 4 are two-way circles (cross-connection will occur during the circle process), that is, the two groups of bracket baselines 4 are respectively circled clockwise and counterclockwise; at the same time, the brackets with the same direction There is a distance between the helices formed around the baseline 4, and the distance between the corresponding helixes intersected by the stent meridian 5 and the stent baseline 4 forms a through hole 3; the through hole 3 can be triangular, quadrilateral, pentagonal, hexagonal, Octagon, ...

specific Embodiment approach 2

[0047] The printing material described in this embodiment also contains medicine.

[0048] Other structures and materials are the same as those in Embodiment 1.

[0049] After shape-memory polycaprolactone, shape-memory polylactic acid, and shape-memory polyurethane are used as printing materials to print scaffolds and implant them in the body, since this printing material has the characteristics of degradation in the body, it is added to the printing material to treat the affected area. The corresponding drugs need to be added according to the actual situation of the affected area. Then as the stent degrades in the body, the drug in the stent is released and promotes endothelialization and tissue growth at the site. That is, the stent of the present invention can be loaded with drugs and implanted.

specific Embodiment approach 3

[0050] When one or more of shape-memory polycaprolactone, shape-memory polylactic acid, and shape-memory polyurethane is used as the printing material in this embodiment, a reinforcing material is added to the printing material, and the reinforcing material includes starch, cellulose, One or more of chitin, lignin, hyaluronic acid and alginic acid.

[0051] Other structures and materials are the same as those in Embodiment 1 or Embodiment 2.

[0052] The strength of the present invention is not only related to the structure of the imitation glass sponge, but also related to the printing material itself. The reinforcing material can not only increase the strength of the stent, but also help the corresponding printing material of the shape memory polymer to adjust the appropriate glass transition temperature, so that the stent can change shape and size according to the preset temperature in the human body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com