Nanosheet TiO2 material, preparation method and application thereof

A technology of nanosheets and hydrolysis reaction, which is applied in the direction of nanotechnology, titanium oxide/hydroxide, electrical components, etc., can solve the problems of limited practical application, low conductivity lithium ion diffusion rate, etc., to improve electrochemical performance, shorten The effect of transmission distance and reduction of calcination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Add 5 mL of butyl titanate to 10 mol / L NaOH solution, and stir rapidly on a magnetic stirrer to disperse the solution evenly. After stirring for 20 min, the white emulsion was transferred to a 100 mL polytetrafluoroethylene reactor, and reacted continuously at 180° C. for 20 h to completely hydrolyze it.

[0030] 2) Add the emulsion obtained in step 1) to the prepared 0.2mol / L dilute hydrochloric acid solution, stir rapidly for 10h, and fully pickle to remove the residual Na on the surface + . Then the above solution was filtered, washed 8 times with deionized water, and then dried in a drying oven at a drying temperature of 50° C. and a drying time of 22 hours.

[0031] 3) The white powder obtained by calcining the dried powder at 450 °C for 4 h in the air atmosphere is the prepared nanosheet TiO 2 Material.

[0032] From figure 1 In the two FE-SEM figures, we can see that we have synthesized nanosheet TiO through the experimental conditions of Example 1 2 mate...

Embodiment 2

[0034] 1) Add 5 mL of butyl titanate to 10 mol / L NaOH solution, and stir rapidly on a magnetic stirrer to disperse the solution evenly. After stirring for 20 min, the white emulsion was transferred to a 100 mL polytetrafluoroethylene reactor, and reacted continuously at 150° C. for 24 h to completely hydrolyze it.

[0035] 2) Add the emulsion obtained in step 1) to the prepared 0.1mol / L dilute hydrochloric acid solution, stir rapidly for 10h, and fully pickle to remove the residual Na on the surface + . Then the above solution was filtered, washed with deionized water for 5 times, and then dried in a drying oven at a drying temperature of 60° C. and a drying time of 20 h.

[0036] Step 3) The white powder obtained after calcining the dried powder at 400°C for 4 hours in an air atmosphere is nanosheet TiO 2 Material.

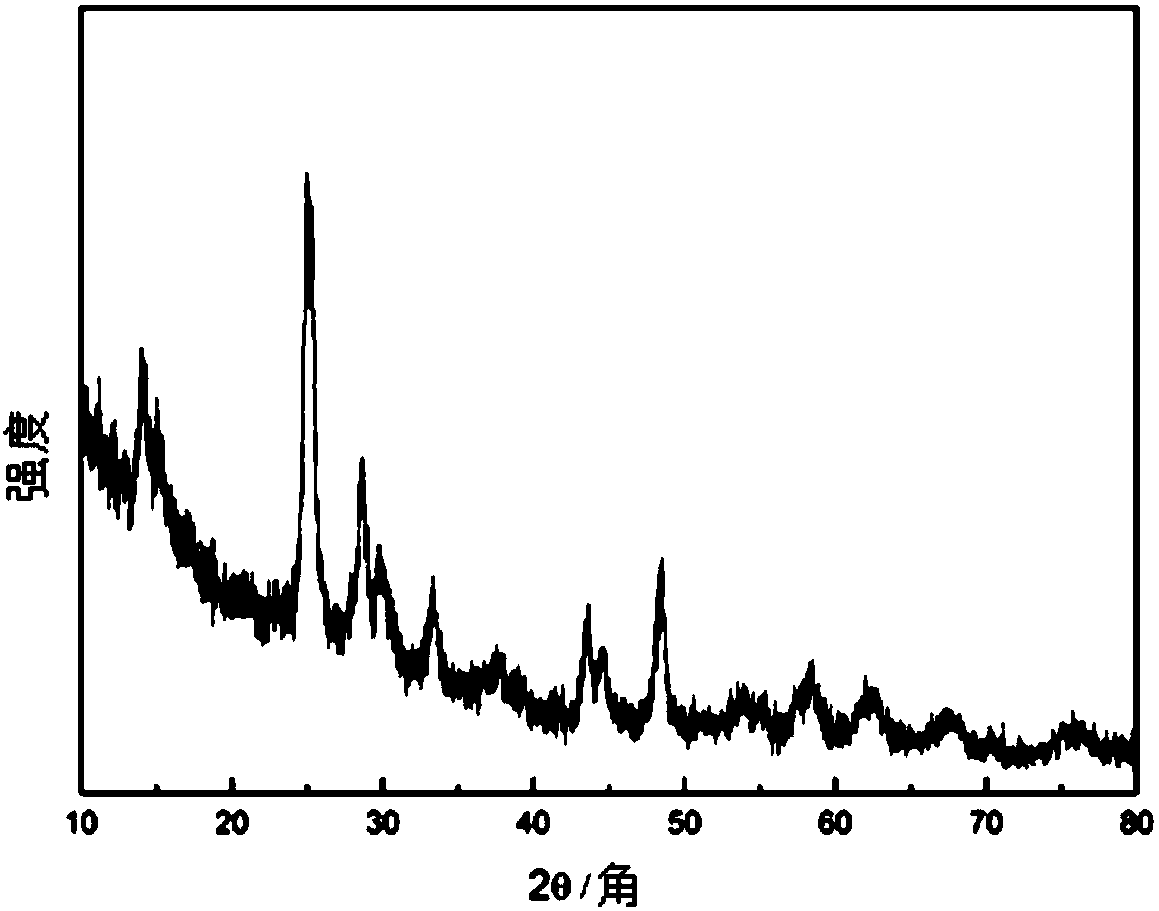

[0037] figure 2 TiO 2 From the XRD pattern of the material, it can be found that the diffraction peaks appearing at 14.18°, 24.96°, 28.62°, and 48.44° corr...

Embodiment 3

[0039] 1) Add 5 mL of butyl titanate to 8 mol / L NaOH solution, and stir rapidly on a magnetic stirrer to disperse the solution evenly. After stirring for 20 min, the white emulsion was transferred to a 100 mL polytetrafluoroethylene reactor, and reacted continuously at 200° C. for 15 h to completely hydrolyze it.

[0040] 2) Add the emulsion obtained in step 1) to the prepared 0.5mol / L dilute hydrochloric acid solution, stir rapidly for 10h, and fully pickle to remove the residual Na on the surface + . Then the above solution was filtered, washed 10 times with deionized water, and then dried in a drying oven at a drying temperature of 70° C. and a drying time of 20 h.

[0041] 3) The white powder obtained by calcining the dried powder at 600 °C for 3 h in an air atmosphere is the prepared nanosheet TiO 2 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com