Environment-friendly building material

A building material and environmental protection technology, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of poor energy saving performance, difficulty in large-scale promotion, limited effect, etc., to avoid the loss of indoor temperature, increase mechanical strength and resistance flammability and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

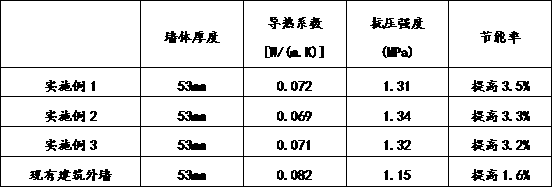

Embodiment 1

[0021] An environmentally friendly building material, comprising a base and an insulating layer, the insulating layer is coated on the base, and the base includes the following raw materials in parts by weight: 3 parts of sepiolite, 25 parts of quartz sand, 4 parts of mineral fiber, silicic acid 1 part of salt, 2 parts of calcium carbonate powder, 6 parts of perlite powder, 2 parts of anti-cracking agent, 8 parts of polystyrene particles, 3 parts of gypsum powder, 12 parts of wetting agent, 5 parts of carbon black, 3 parts of polyvinyl chloride, 12 parts of talcum powder, 2 parts of cellulose powder; the insulation layer includes the following raw materials in parts by weight: 8 parts of epoxy resin, 0.8 part of bamboo charcoal fiber, 2.5 parts of silicon-acrylic emulsion, 0.3 part of aluminum hydroxide, 0.1 part of latex powder, 3 parts of water-based glue, 0.1 part of antifungal agent, 0.01 part of acid-base regulator, 4 parts of ethylene glycol, 0.1 part of silicone oil, 6 p...

Embodiment 2

[0032] An environmentally friendly building material, comprising a base and an insulating layer, the insulating layer is coated on the base, and the base includes the following raw materials in parts by weight: 5 parts of sepiolite, 56 parts of quartz sand, 6 parts of mineral fiber, silicic acid 2 parts of salt, 4 parts of calcium carbonate powder, 10 parts of perlite powder, 5 parts of anti-cracking agent, 10 parts of polystyrene particles, 5 parts of gypsum powder, 24 parts of wetting agent, 13 parts of carbon black, 9 parts of polyvinyl chloride, 18 parts of talcum powder and 8 parts of cellulose powder; the heat-insulating layer includes the following raw materials in parts by weight: 10 parts of epoxy resin, 1.5 parts of bamboo charcoal fiber, 4 parts of silicon-acrylic emulsion, 0.5 part of aluminum hydroxide, 0.5 part of latex powder, 4 parts of water-based glue, 0.2 parts of antifungal agent, 0.02 parts of acid-base regulator, 4.5 parts of ethylene glycol, 0.5 parts of ...

Embodiment 3

[0043] An environmentally friendly building material, comprising a base and an insulating layer, the insulating layer is coated on the base, and the base includes the following raw materials in parts by weight: 4 parts of sepiolite, 40 parts of quartz sand, 5 parts of mineral fiber, silicic acid 1.5 parts of salt, 3 parts of calcium carbonate powder, 8 parts of perlite powder, 3.5 parts of anti-cracking agent, 9 parts of polystyrene particles, 4 parts of gypsum powder, 18 parts of wetting agent, 9 parts of carbon black, 6 parts of polyvinyl chloride, 15 parts of talcum powder, 5 parts of cellulose powder; The heat insulation layer includes the following raw materials in parts by weight: 9 parts of epoxy resin, 1.15 parts of bamboo charcoal fiber, 3.5 parts of silicon-acrylic emulsion, 0.4 part of aluminum hydroxide, 0.3 part of latex powder, 3.5 parts of water-based glue, 0.15 parts of antifungal agent, 0.015 parts of acid-base regulator, 4.25 parts of ethylene glycol, 0.3 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com