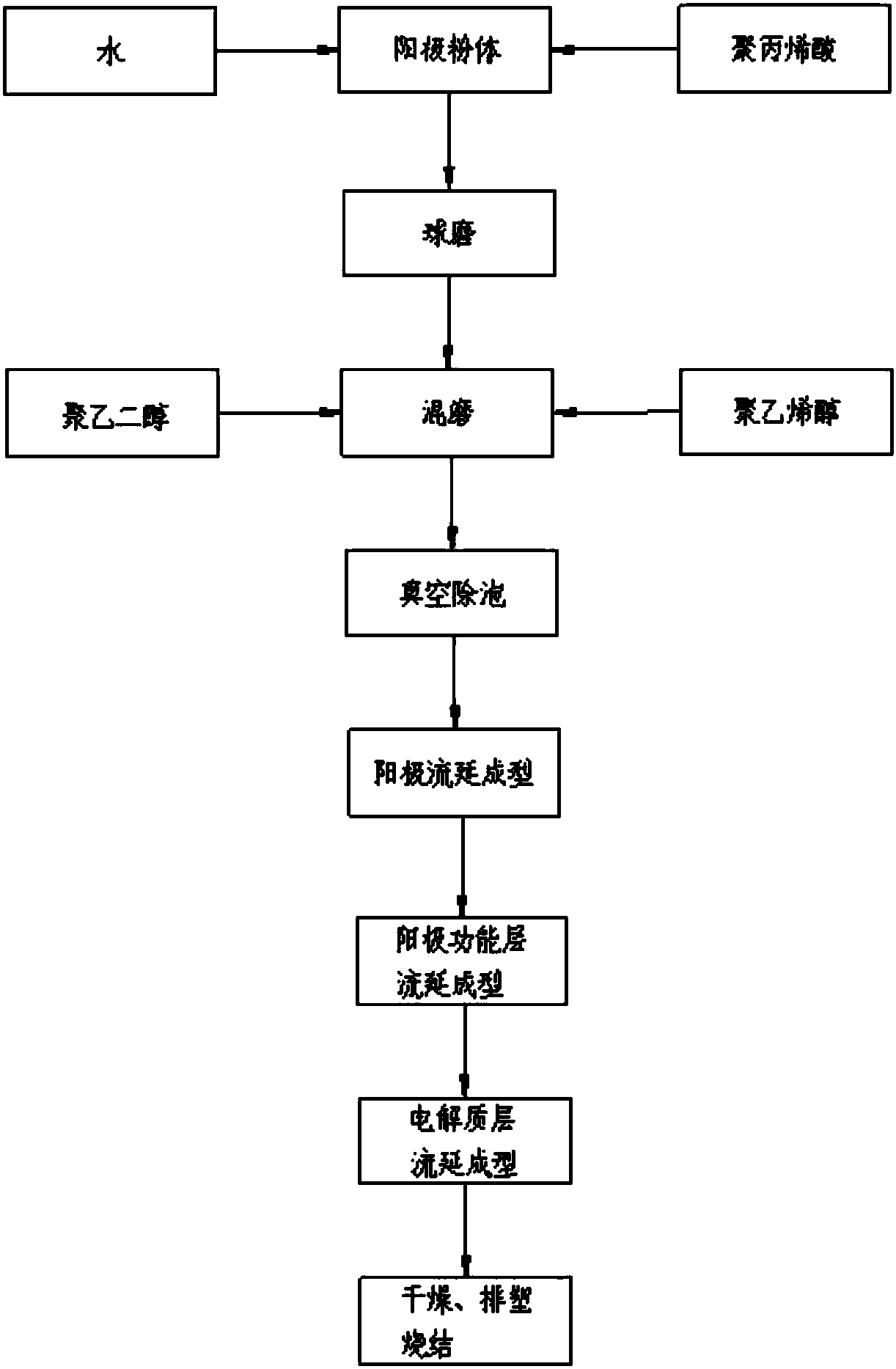

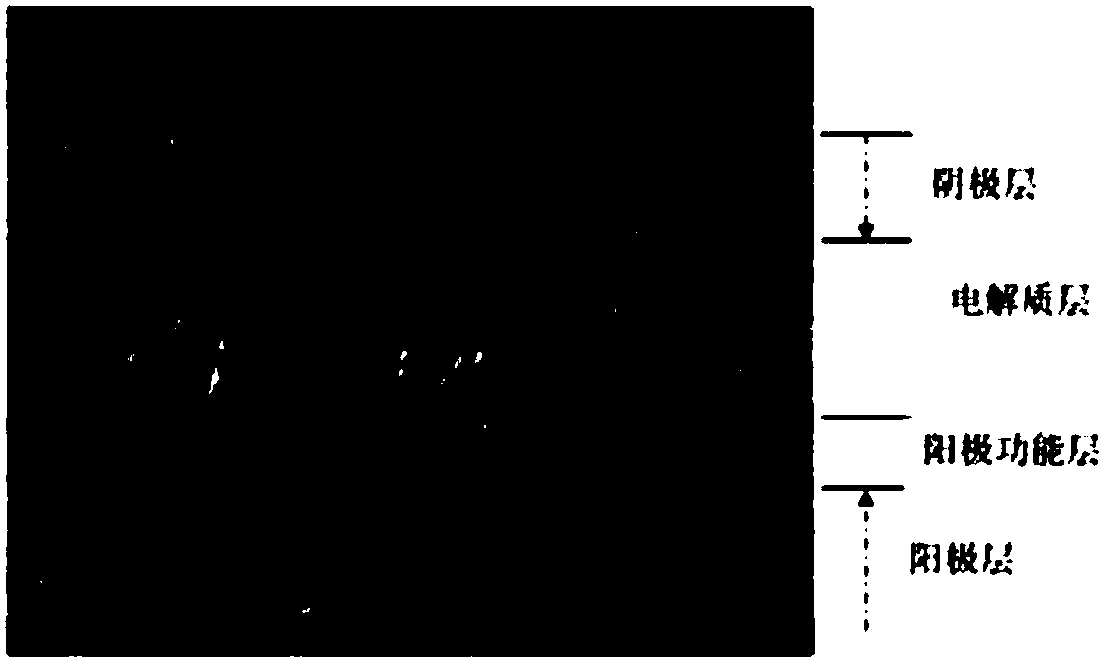

Method for preparing medium temperature SOFC monocell with anode functional layer by multi-layer aqueous tape casting

A functional layer, single cell technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of uneven density, complex processing, high cost, achieve long three-phase reaction interface, improve preparation efficiency, and excellent water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

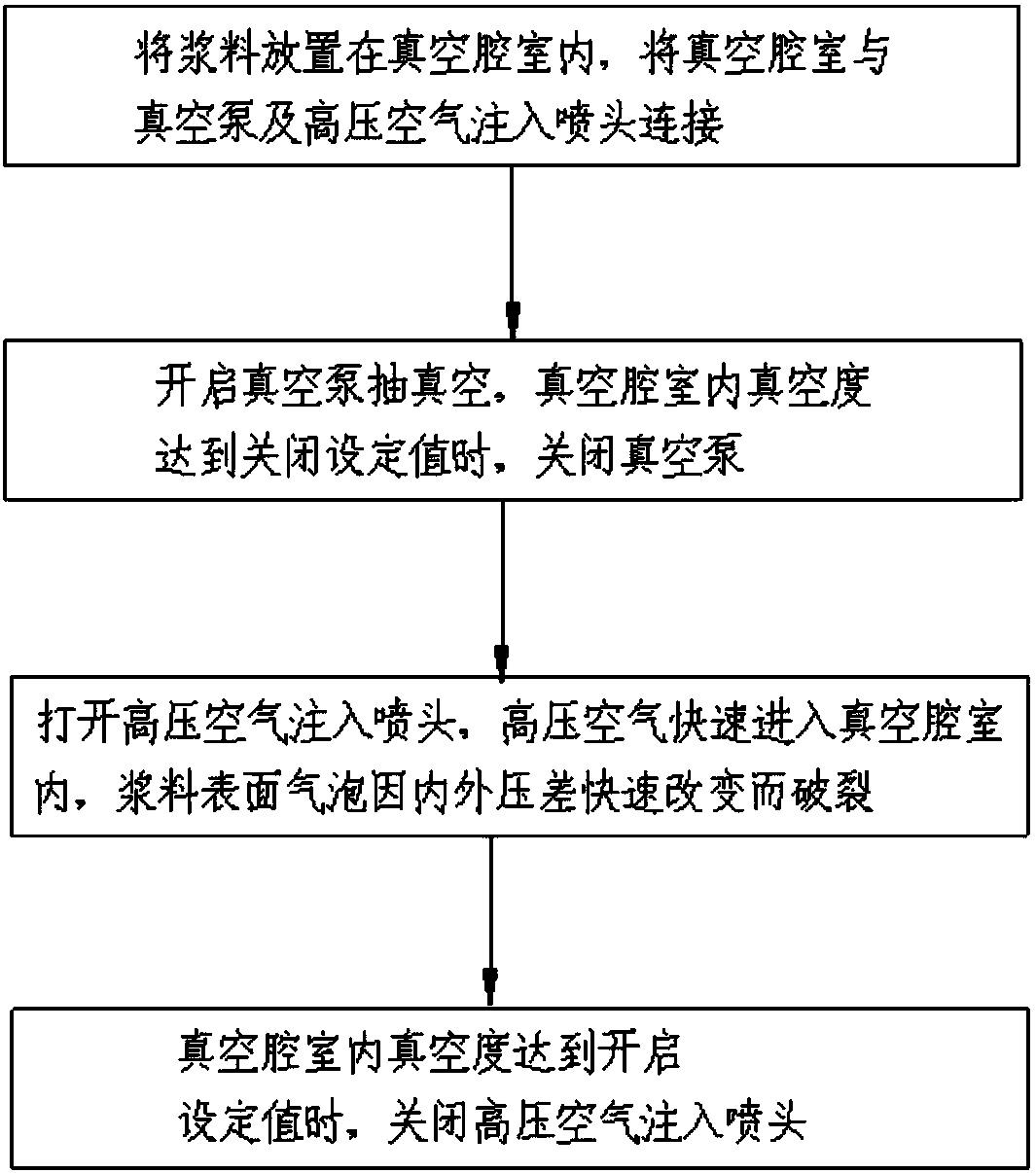

Method used

Image

Examples

Embodiment 1

[0034] The surfactant components in Step A, Step B, and Step C include 10 parts by weight of nonylphenol polyoxyethylene ether, 5 parts of amino polyether silicone, 3 parts of thickener, and 2 parts of dibromoethane , 4 parts of sodium lauryl sulfate, 8 parts of alkyl phenyl.

[0035] In this embodiment, in step D, the ejection parameter is 600°C, the heating rate is 1°C / min; the optimum high-temperature sintering condition is 1450°C, the heating rate is 5°C / min, and the holding time is 5 hours.

[0036] In this embodiment, the ball milling speeds in step A, step B, and step C are all 350 rpm.

Embodiment 2

[0038] The surfactant components in Step A, Step B, and Step C include 20 parts by weight of nonylphenol polyoxyethylene ether, 15 parts of amino polyether silicone, 9 parts of thickener, and 8 parts of dibromoethane , 12 parts of sodium lauryl sulfate, 20 parts of alkyl phenyl.

[0039] In this embodiment, in step D, the ejection parameter is 650°C, the heating rate is 3°C / min; the optimum high-temperature sintering condition is 1550°C, the heating rate is 8°C / min, and the holding time is 7 hours.

[0040] In this embodiment, the ball milling speeds in step A, step B, and step C are all 450 rpm.

Embodiment 3

[0042] The surfactant components in step A, step B, and step C include 14 parts by weight of nonylphenol polyoxyethylene ether, 12 parts of amino polyether silicone, 5 parts of thickener, and 7 parts of dibromoethane , 10 parts of sodium lauryl sulfate, 12 parts of alkyl phenyl.

[0043] In this embodiment, in step D, the ejection parameter is 610°C, the heating rate is 3°C / min; the optimum high-temperature sintering condition is 1480°C, the heating rate is 6°C / min, and the holding time is 7 hours.

[0044] In this embodiment, the ball milling speeds in step A, step B, and step C are all 380 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com