Miniature exhaust-free hydrogen peroxide synthesizing device and method

A technology for hydrogen peroxide and tail gas emissions, applied in chemical instruments and methods, peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, inorganic chemistry, etc., can solve the reaction and separation process efficiency Low, long stay, bulky equipment and other problems, to avoid emptying or recycling, reduce production equipment, reduce the size of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

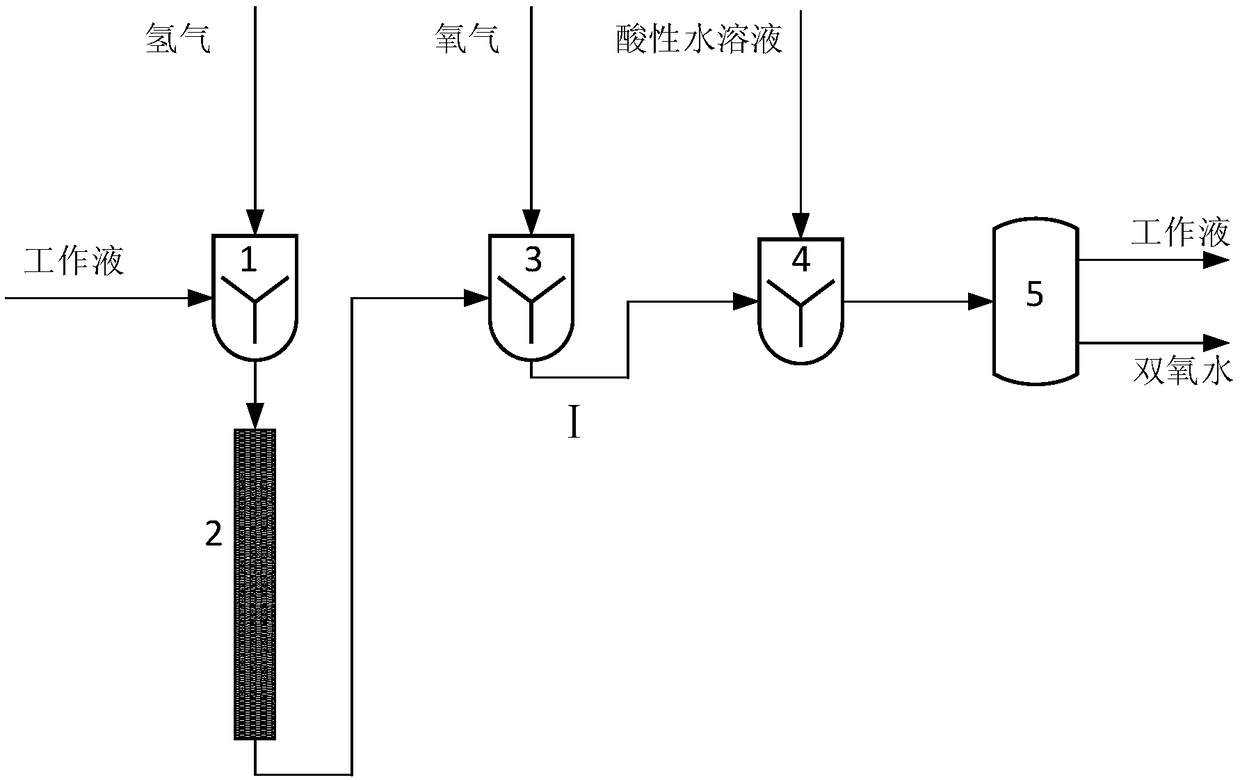

[0025] in such as figure 1 In the shown device, hydrogen peroxide is synthesized, and the concrete steps are as follows:

[0026] (1) Configure the working solution containing anthraquinone derivatives

[0027] Mix m-trimethylbenzene and trioctyl phosphate to form a solvent, wherein the volume fraction of trioctyl phosphate is 25%; mix 2-ethylanthraquinone with the solvent as a solute to obtain a concentration of 2-ethylanthraquinone of 0.6 mol / L working solution.

[0028] (2) hydrogenation reaction

[0029] At a temperature of 60°C and a pressure of 200kPa (gauge pressure), pass a total of 0.02mol of hydrogen and 400mL of the working fluid obtained in step (1) into the hydrogenation membrane microdisperser 1 to obtain the average diameter of the bubbles Gas-liquid mixed fluid A of 10 microns;

[0030] Be that temperature is 60 ℃, pressure is under the condition of 200kPa (gauge pressure), make gas-liquid mixed fluid A flow through and be filled with the micro-packed bed ...

Embodiment 2

[0036] in such as figure 1 In the shown device, hydrogen peroxide is synthesized, and the concrete steps are as follows:

[0037] (1) Configure the working solution containing anthraquinone derivatives

[0038] Mix m-trimethylbenzene and trioctyl phosphate to form a solvent, wherein the volume fraction of trioctyl phosphate is 25%; mix 2-ethylanthraquinone and tetrahydro 2-ethylanthraquinone as solutes with the solvent to obtain 2- The total concentration of ethylanthraquinone and tetrahydro 2-ethylanthraquinone is 0.2mol / L working solution.

[0039] (2) hydrogenation reaction

[0040] At a temperature of 50°C and a pressure of 500kPa (gauge pressure), pass a total of 0.01mol of hydrogen and 400mL of the working fluid obtained in step (1) into the hydrogenation membrane microdisperser 1 to obtain the average diameter of the bubbles A gas-liquid mixed fluid A of 200 microns;

[0041] The temperature is 50 DEG C, and the pressure is under the condition of 500kPa (gauge press...

Embodiment 3

[0047] in such as figure 1 In the shown device, hydrogen peroxide is synthesized, and the concrete steps are as follows:

[0048] (1) Configure the working solution containing anthraquinone derivatives

[0049] Mix m-trimethylbenzene and trioctyl phosphate to form a solvent, wherein the volume fraction of trioctyl phosphate is 25%; mix 2-ethylanthraquinone as a solute with the solvent to obtain a concentration of 2-ethylanthraquinone of 0.8mol / L working solution.

[0050] (2) hydrogenation reaction

[0051] At a temperature of 60°C and a pressure of 600kPa (gauge pressure), pass a total of 0.08mol of hydrogen and 400mL of the working fluid obtained in step (1) into the hydrogenation membrane microdisperser 1 to obtain the average diameter of the bubbles A gas-liquid mixed fluid A of 100 microns;

[0052] Be that temperature is 60 ℃, pressure is under the condition of 600kPa (gauge pressure), make gas-liquid mixed fluid A flow through and be filled with the micro-packed be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com