Low temperature-resistant cable sheath material and preparation method thereof

A sheath material, low temperature resistance technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of short service life, poor anti-aging and wear resistance, and unsatisfactory low temperature resistance, and achieve simplification The preparation method has the advantages of excellent low temperature resistance and excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

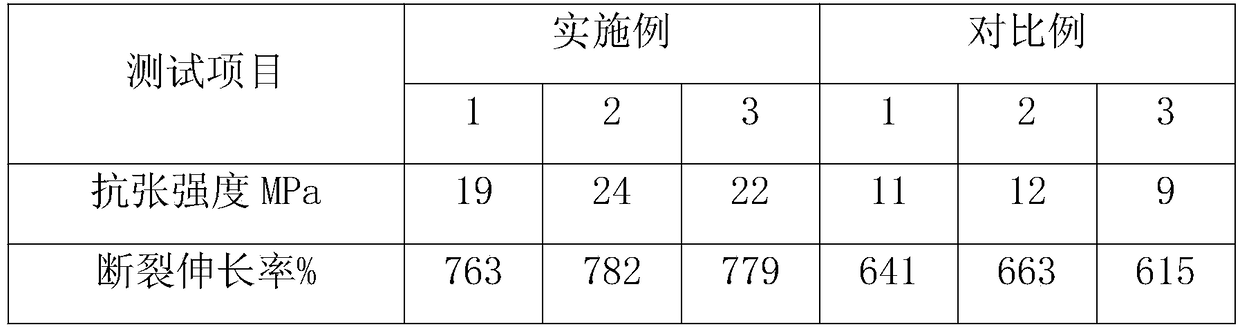

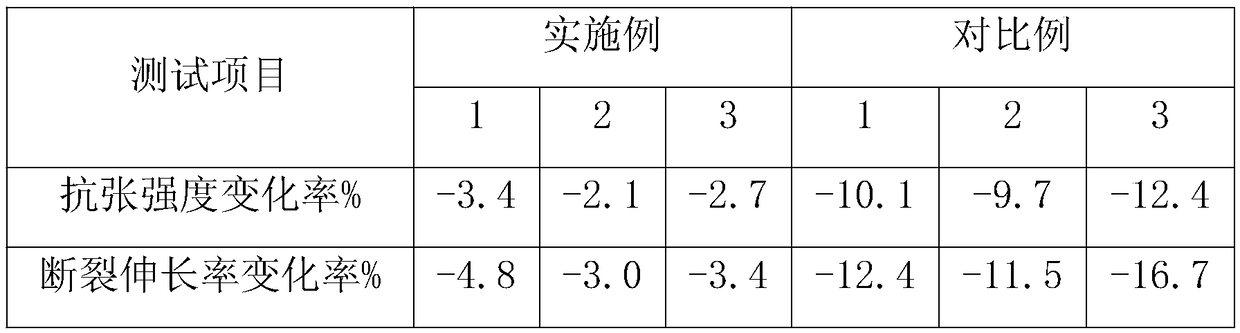

Examples

Embodiment 1

[0019] A low temperature resistant cable sheath material proposed by the present invention comprises the following raw materials in parts by weight: 90 parts of ethylene-vinyl acetate copolymer, 20 parts of bisphenol A polyarylate, 1 part of polyphenylene sulfide fiber, oxidized 5 parts of calcium, 5 parts of paraffin oil, 0.6 part of diisononyl phthalate, 0.3 part of terephthalate, 0.15 part of light stabilizer; the light stabilizer is carbon black and 4-hydroxybenzoyl The composition of ketone, and the mass ratio of carbon black and 4-hydroxybenzophenone is 2:3;

[0020] Its preparation method comprises the following steps:

[0021] S1. According to 90 parts of ethylene-vinyl acetate copolymer, 20 parts of bisphenol A polyarylate, 1 part of polyphenylene sulfide fiber, 5 parts of calcium oxide, 5 parts of paraffin oil, and 0.6 part of diisononyl phthalate , 0.3 part of terephthalic acid ester, 0.15 part of light stabilizer, each raw material is weighed, for subsequent use; ...

Embodiment 2

[0026] A low-temperature-resistant cable sheath material proposed by the present invention includes the following raw materials in parts by weight: 100 parts of ethylene-vinyl acetate copolymer, 30 parts of bisphenol A polyarylate, 2.5 parts of polyphenylene sulfide fiber, oxidized 10 parts of calcium, 10 parts of paraffin oil, 0.4 part of diisononyl phthalate, 0.2 part of terephthalate, 0.1 part of light stabilizer; the light stabilizer is carbon black and 4-hydroxybenzoyl The composition of ketone, and the mass ratio of carbon black and 4-hydroxybenzophenone is 3:4;

[0027] Its preparation method comprises the following steps:

[0028] S1. According to 100 parts of ethylene-vinyl acetate copolymer, 30 parts of bisphenol A polyarylate, 2.5 parts of polyphenylene sulfide fiber, 10 parts of calcium oxide, 10 parts of paraffin oil, and 0.4 part of diisononyl phthalate , 0.2 part of terephthalic acid ester, 0.1 part of light stabilizer Weigh each raw material, set aside;

[00...

Embodiment 3

[0033] A low temperature resistant cable sheath material proposed by the present invention comprises the following raw materials in parts by weight: 110 parts of ethylene-vinyl acetate copolymer, 40 parts of bisphenol A polyarylate, 5 parts of polyphenylene sulfide fiber, oxidized 15 parts of calcium, 15 parts of paraffin oil, 0.2 part of diisononyl phthalate, 0.1 part of terephthalate, 0.05 part of light stabilizer; the light stabilizer is carbon black and 4-hydroxybenzoyl The composition of ketone, and the mass ratio of carbon black and 4-hydroxybenzophenone is 3:5;

[0034] Its preparation method comprises the following steps:

[0035] S1. According to 110 parts of ethylene-vinyl acetate copolymer, 40 parts of bisphenol A polyarylate, 5 parts of polyphenylene sulfide fiber, 15 parts of calcium oxide, 15 parts of paraffin oil, and 0.2 parts of diisononyl phthalate , 0.1 part of terephthalic acid ester, 0.05 part of light stabilizer, each raw material is weighed and set asid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com