Preparation method of stainless steel aluminum coating

A kind of stainless steel and aluminum coating technology, applied in coating, metal material coating process, solid diffusion coating and other directions, can solve the complex operation process of hot dip aluminum process, poor high temperature performance of products, low efficiency of aluminizing process, etc. problems, to achieve the effect of simple and feasible preparation method, low shape requirements, easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The molten salt system in this embodiment is the FLiNaK molten salt system.

[0033] ① Pretreatment of 316L stainless steel

[0034] Cut the 316L stainless steel into a sample with a size of 15mm×5mm×1mm by wire cutting method, and punch a hole with a diameter of φ2mm on the sample. The surface of all samples was polished step by step with SiC sandpaper to 2000 mesh, then ultrasonically cleaned with deionized water and absolute ethanol in sequence, and dried with a hair dryer and cold air.

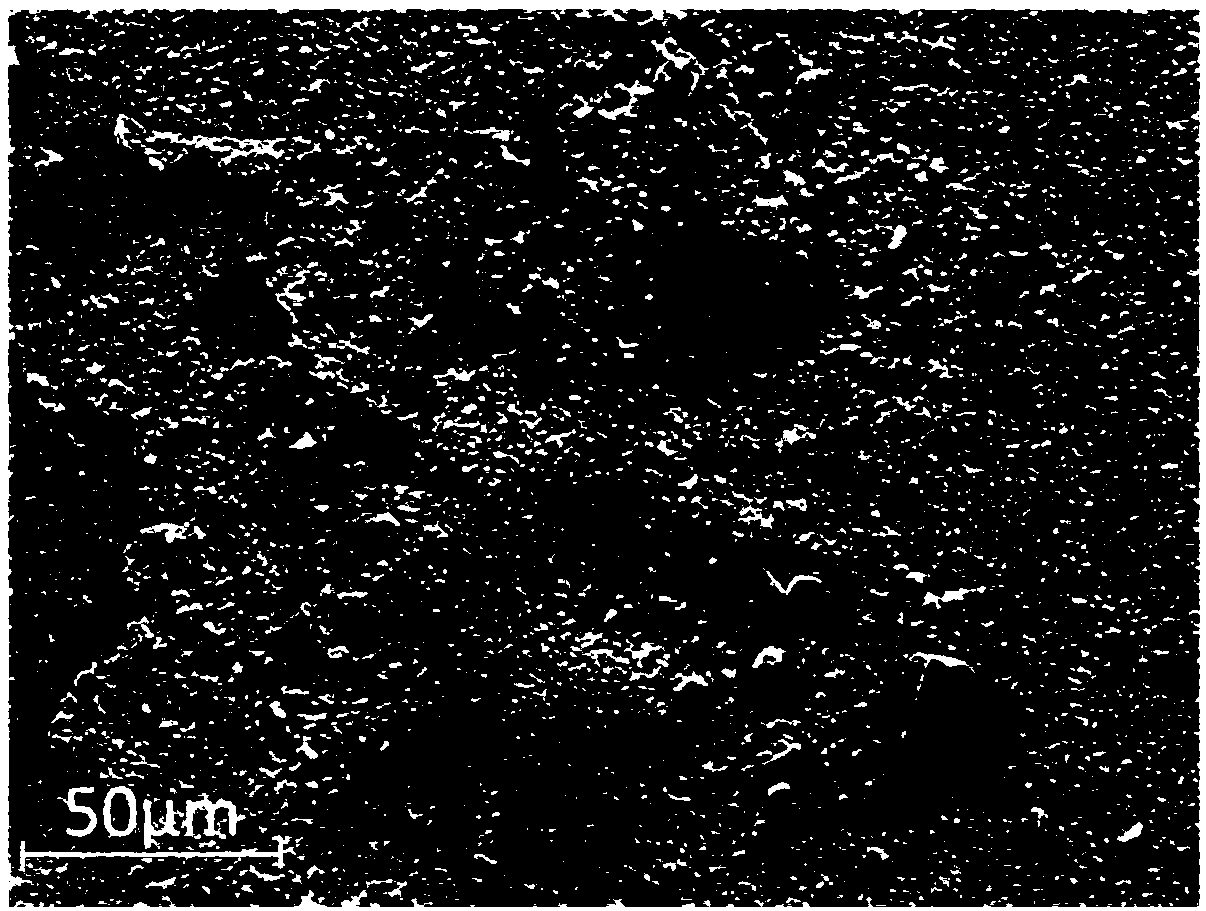

[0035] ② 316L stainless steel aluminized in FLiNaK molten salt at 700 °C

[0036] Add the pretreated 316L stainless steel sample into a stainless steel crucible, weigh 200g of solid LiF-KF-NaF (46.5-11.5-42mol%, FLiNaK) salt, then add 5000ppm of aluminum powder (200 mesh, 4N )well mixed. Add the mixed salt into the crucible, put it into an atmosphere-protected muffle furnace, and keep it at a constant temperature of 700°C for 48h. In order to avoid impurities such as oxygen and ...

Embodiment 2

[0038] The molten salt system in this example is NaCl-KCl-MgCl 2 (33-21.6-45.4mol%) system.

[0039] ① Pretreatment of 316L stainless steel

[0040] Cut the 316L stainless steel into a sample with a size of 15mm×5mm×1mm by wire cutting method, and punch a hole with a diameter of φ2mm on the sample. The surface of all samples was polished step by step with SiC sandpaper to 2000 mesh, then ultrasonically cleaned with deionized water and absolute ethanol in sequence, and dried with a hair dryer and cold air.

[0041] ② 316L stainless steel is aluminized in chlorine salt at 700 °C

[0042] Add the pretreated 316L stainless steel sample into a stainless steel crucible, weigh 200g of solid NaCl-KCl-MgCl 2 (33-21.6-45.4mol%) salt, then add 2000ppm of aluminum powder (100 mesh particle size) to the chloride salt and mix well. Add the mixed salt into the crucible, put it into an atmosphere-protected muffle furnace, and keep it at a constant temperature of 700°C for 48h. In order t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com