Multi-layer electrode structure for lithium sulfur battery and preparation method thereof

A technology for multi-layer electrodes and lithium-sulfur batteries, applied in battery electrodes, non-aqueous electrolyte battery electrodes, structural parts, etc., can solve the problems of poor cycle stability and low sulfur utilization rate, achieve simple and easy process, and realize stable cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

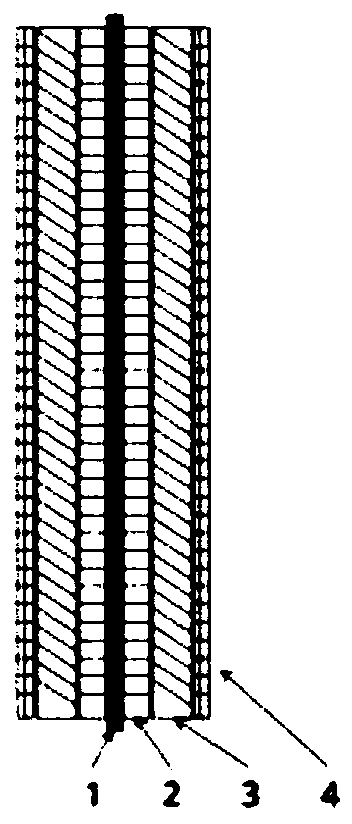

[0043] Select a porous aluminum foil current collector (50% porosity), select carbon fibers with a diameter of 7 microns to disperse in an ethanol-water mixed solution and spray on the surface of the selected current collector, evaporate the solvent at 60 degrees to obtain a loose porous layer on the electrode surface , the thickness of the coating is 25 microns, and the porosity is 85%.

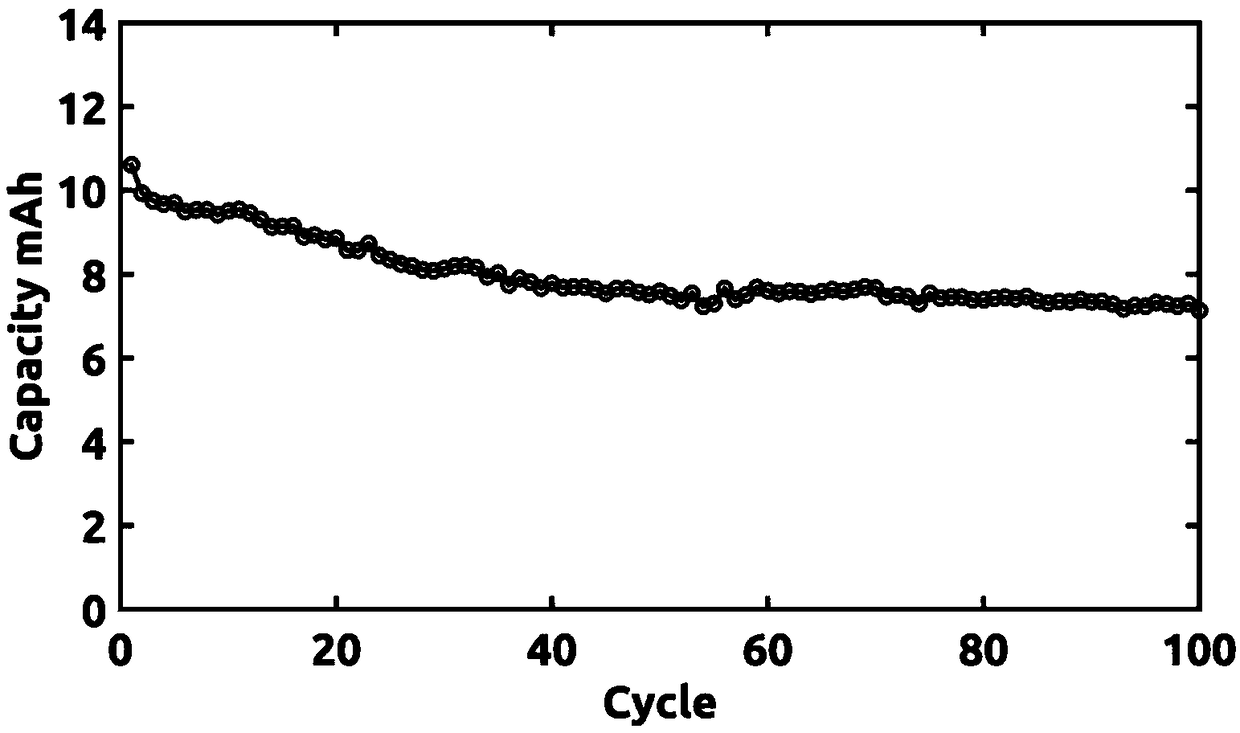

[0044] Choose the graphene sample of comparative example, be dispersed in N-methylpyrrolidone (NMP) with elemental sulfur, polyvinylidene fluoride in the ratio of mass ratio 5:85:10, will be mixed with graphene sample, elemental sulfur and polyvinylidene fluoride N-methylpyrrolidone (NMP) of vinyl fluoride is fully mechanically mixed and scraped on the surface of the above electrode, dried in vacuum at 100 degrees, and then mechanically rolled to obtain an electrode sheet with a thickness of 250 microns. The graphene oxide aqueous solution was spray-coated on the surface of the electrode, an...

Embodiment 2

[0047] Select a copper foil current collector with holes (porosity 65%), select carbon fibers with a diameter of 6 microns to disperse in an ethanol-water mixed solution and spray on the surface of the selected current collector, and evaporate the solvent at 60 degrees to obtain a loose and porous electrode surface layer, the thickness of the coating is 20 microns, and the porosity is 64%.

[0048] Choose the graphene sample of comparative example, disperse in the acetonitrile solution with elemental sulfur, polyethylene oxide in the ratio of mass ratio 5:87:8, will be mixed with the N- Methylpyrrolidone (NMP) was fully mechanically mixed and scraped on the surface of the above electrode, dried in vacuum at 60°C, and then mechanically rolled to obtain an electrode sheet with a thickness of 265 microns. The graphene oxide aqueous solution was spray-coated on the surface of the electrode, and the D50 of the graphene oxide sheet was 47 microns. After drying, the final electrode w...

Embodiment 3

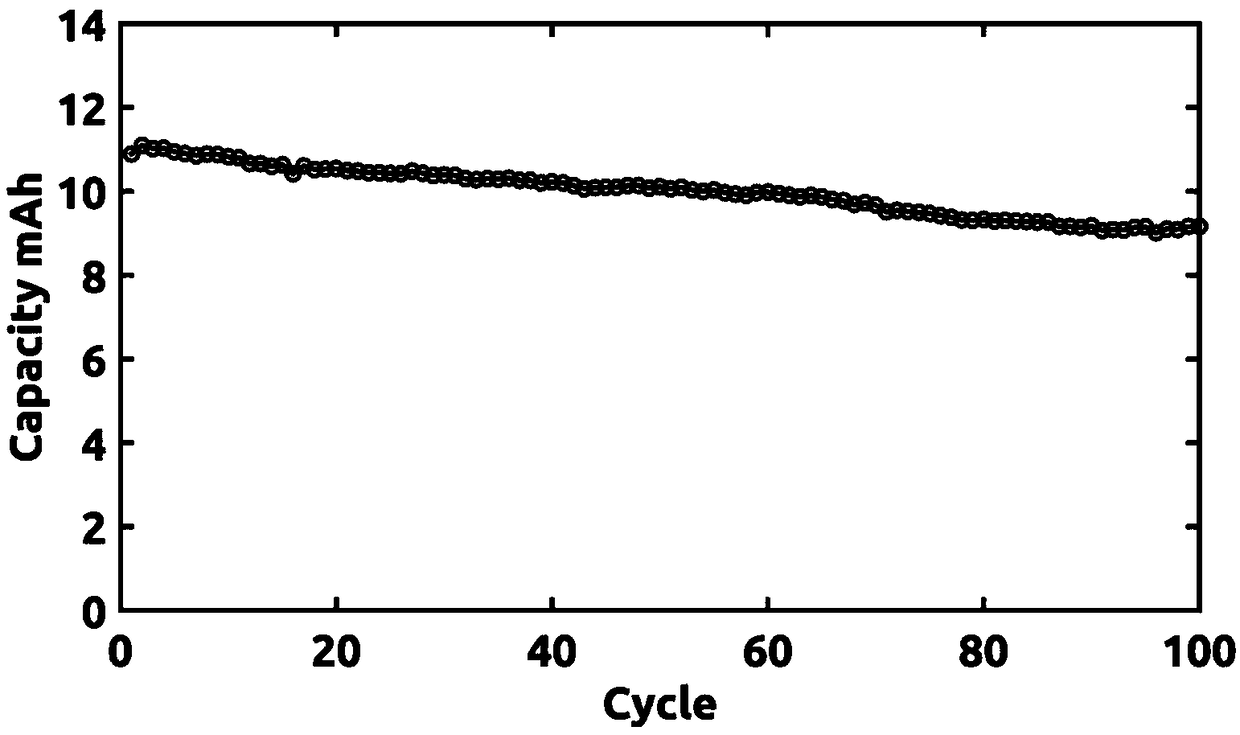

[0051] Select a porous aluminum foil current collector (porosity 45%), select carbon fibers with a diameter of 3 microns to disperse in an ethanol-water mixed solution and spray on the surface of the selected current collector, evaporate the solvent at 60 degrees to obtain a loose porous layer on the electrode surface , the thickness of the coating is 45 microns, and the porosity is 74%.

[0052] Select D50 as a 76 micron graphene sample, disperse it in the NMP solution with elemental sulfur and polyvinylidene fluoride in a mass ratio of 5:90:5, mix the N- Methylpyrrolidone (NMP) was fully mechanically mixed and scraped onto the surface of the electrode, dried in a vacuum at 100 degrees, and then mechanically rolled to obtain an electrode sheet with a thickness of 310 microns. The graphene oxide aqueous solution was sprayed on the surface of the electrode, and the D50 of the graphene oxide sheet was 220 microns. After drying, the final electrode was obtained, and the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com