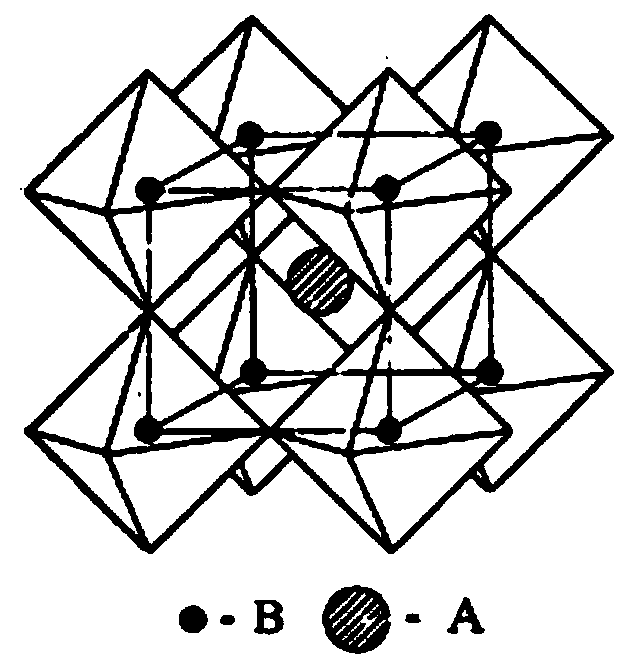

Preparation method of vanadium-doped strontium titanate photocatalytic nanomaterial

A catalytic material, strontium titanate technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of large microstructure adjustability of materials , to achieve the effect of low preparation cost, simple method and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

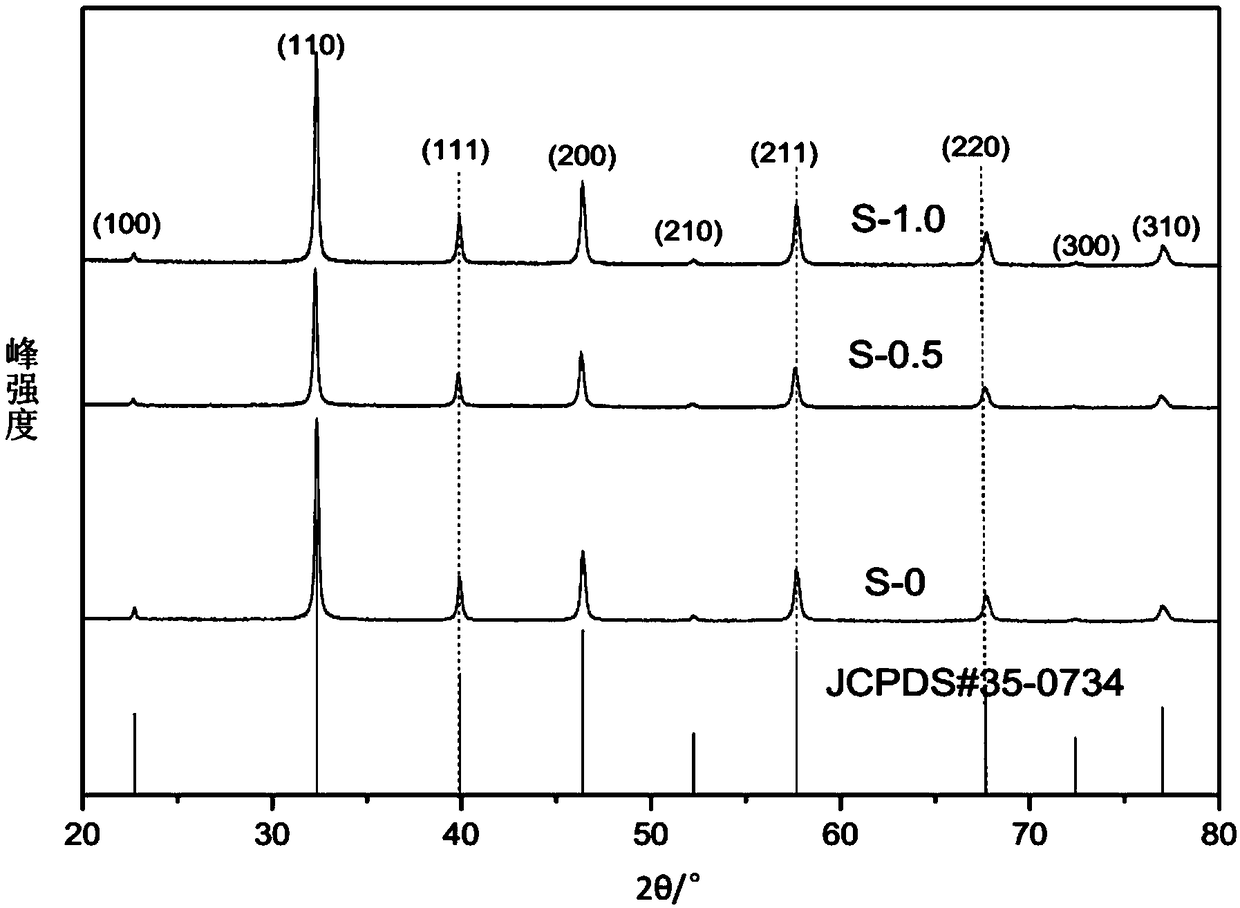

Embodiment 1

[0034] 1. Weigh 2.11g (0.01mol) Sr(NO 3 ) 2 Dissolve in 20ml deionized water, stir until completely dissolved;

[0035] 2. Add 2.8ml (C) dropwise to the solution obtained in a. 3 h 7 O) 4 Ti (ρ=0.9600g / mL), stirring while adding, to obtain a white suspension system as dispersed as possible;

[0036]3. Immediately add 0.8g NaOH to the mixed system obtained in b, and set the volume to 40ml (the concentration of NaOH is 0.5mol / L);

[0037] 4. Use an ultrasonic disperser to fully dissolve the Chinese medicine c, transfer it to a 50ml hydrothermal reaction kettle, and keep it warm at 200°C for 24 hours;

[0038] 5. The obtained SrTiO 3 A small amount of SrCO was washed away with 1% dilute nitric acid solution 3 , and then washed with deionized water, dried at 80°C for later use, and the obtained white solid powder is undoped pure phase strontium titanate.

Embodiment 2

[0040] 1. Weigh 2.11g (0.01mol) Sr(NO 3 ) 2 Dissolve in 20ml deionized water, stir until completely dissolved;

[0041] 2. Add 2.8ml (C) dropwise to the solution obtained in a. 3 h 7 O) 4 Ti (ρ=0.9600g / mL), stirring while adding, to obtain a white suspension system as dispersed as possible;

[0042] 3. Put 0.0045g of V 2 o 5 Add the mixed system obtained in b, while fully stirring, then add 0.8g NaOH, and set the volume to 40ml (the concentration of NaOH is 0.5mol / L);

[0043] 4. Use an ultrasonic disperser to fully dissolve the Chinese medicine c, transfer it to a 50ml hydrothermal reaction kettle, and keep it warm at 200°C for 24 hours;

[0044] 5. The obtained SrTiO 3 A small amount of SrCO was washed away with 1% dilute nitric acid solution 3 , and then washed with deionized water, dried at 80° C. for later use, and the obtained yellow solid powder is vanadium-doped strontium titanate with a doping amount of 0.5 mol%.

Embodiment 3

[0046] 1. Weigh 2.11g (0.01mol) Sr(NO 3 ) 2 Dissolve in 20ml deionized water, stir until completely dissolved;

[0047] 2. Add 2.8ml (C) dropwise to the solution obtained in a. 3 h 7 O) 4 Ti (ρ=0.9600g / mL), stirring while adding, to obtain a white suspension system as dispersed as possible;

[0048] 3. Add 0.0091g of V 2 o 5 Add the mixed system obtained in b, while fully stirring, then add 0.8g NaOH, and set the volume to 40ml (the concentration of NaOH is 0.5mol / L);

[0049] 4. Use an ultrasonic disperser to fully dissolve the Chinese medicine c, transfer it to a 50ml hydrothermal reaction kettle, and keep it warm at 200°C for 24 hours;

[0050] 5. The obtained SrTiO 3 A small amount of SrCO was washed away with 1% dilute nitric acid solution 3 , and then washed with deionized water, dried at 80° C. for later use, and the obtained yellow solid powder is vanadium-doped strontium titanate with a doping amount of 1.0 mol%.

[0051] Do a series of tests for embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com