Preparation method of graphene-loaded copper nanoparticle

A graphene and copper nanotechnology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as harsh experimental conditions, and achieve the effect of reducing variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 10ml of the prepared saturated aqueous solution of copper nitrate and copper acetate salt with a measuring cylinder, add them into 0.5g of graphene oxide obtained after freeze-drying, ultrasonicate for 1h, and then magnetically stir at room temperature for 12h. After filtering and vacuum drying for 12 hours, a brown cake-like product, that is, a graphene-loaded copper salt product, was obtained. Fully grind the brown cake-like product, weigh the two products with a mass of 1 g in a quartz boat, put them into a tube furnace to set the temperature, and pass in an inert gas protection, and heat up and roast for 3 hours. In this experiment, the composition of substances in the product was investigated when the roasting temperature was 400°C, 450°C, and 500°C.

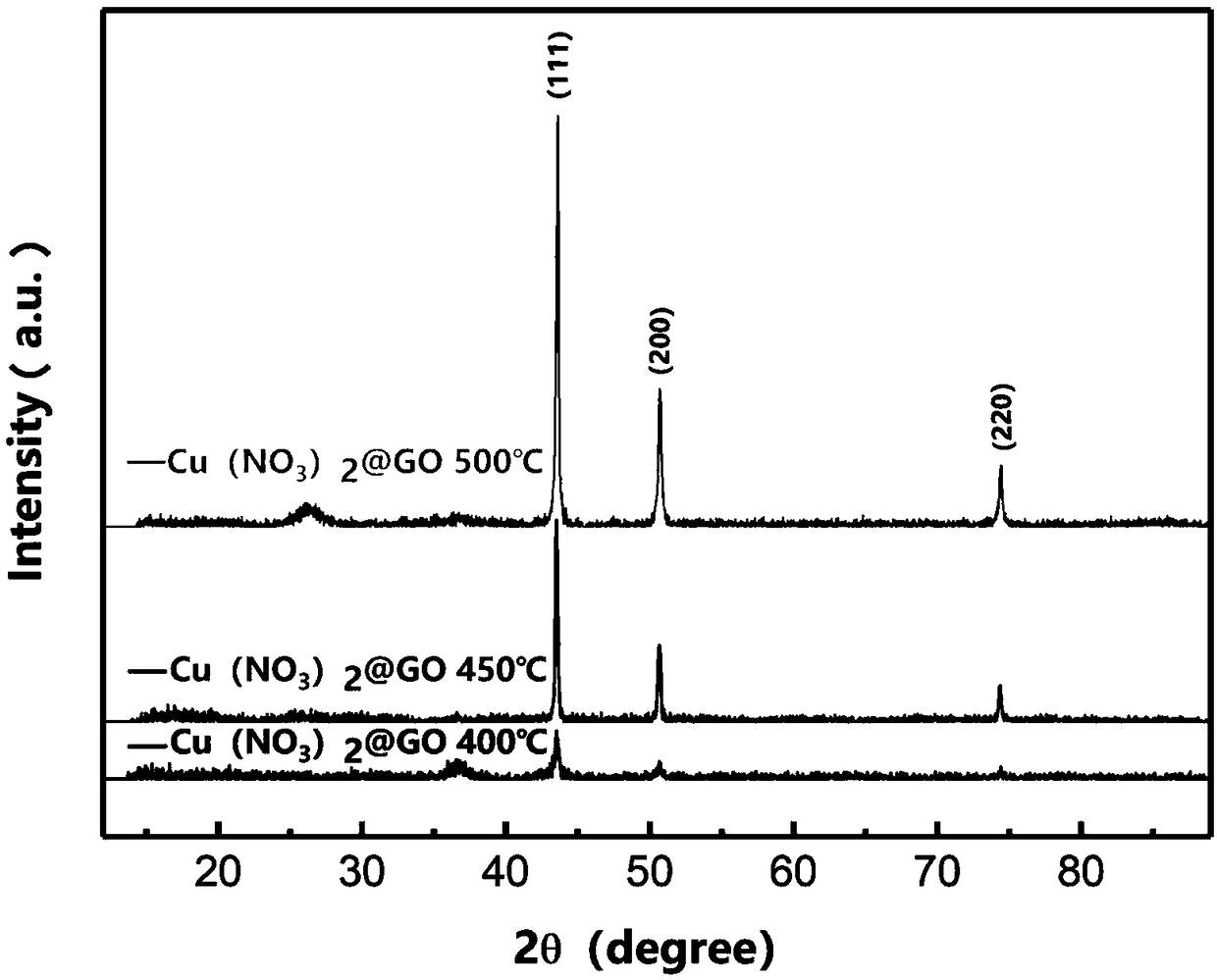

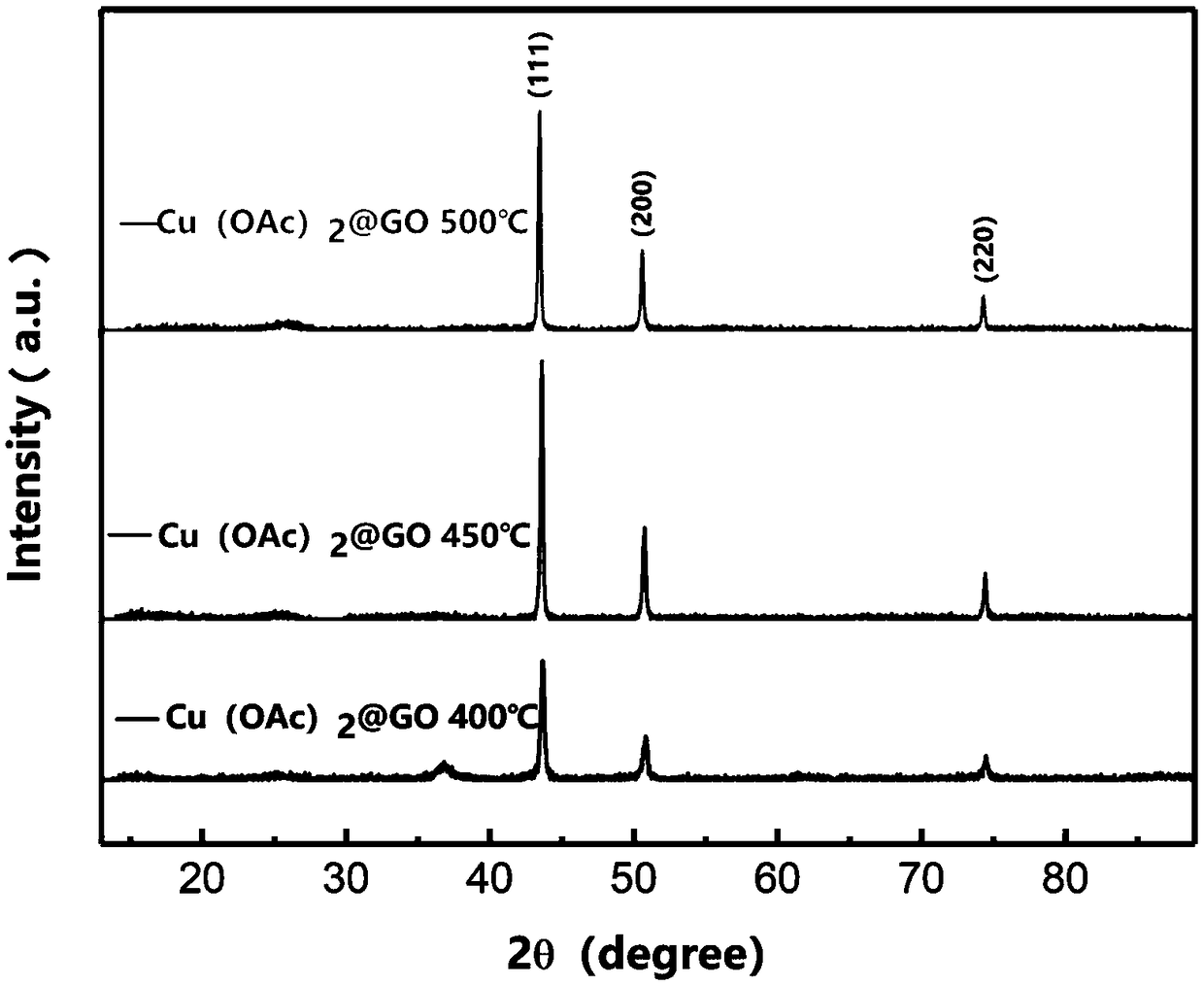

[0025] Using XRD, the samples after roasting were characterized:

[0026] figure 1 The XRD spectrum of the sample drawn after the test of copper nitrate and graphene oxide baked at 400°C-500°C,

[0027] fi...

Embodiment 2

[0030] Weigh 5 ml of the prepared saturated aqueous solution of copper nitrate and copper salt with a measuring cylinder, add it to 0.5 g of graphene oxide obtained after freeze-drying, ultrasonicate for 1 h, and magnetically stir for 12 h at room temperature. After filtering and vacuum drying for 12 hours, a brown cake-like product, that is, a graphene-loaded copper salt product, was obtained. Fully grind the brown cake-like product, weigh 1 g of the product in a quartz boat, put it into a tube furnace to set the temperature, and pass in an inert gas protection, and heat up and roast for 3 hours. In this experiment, the distribution and size of copper nanoparticles were investigated when copper nitrate was used as a copper salt precursor and graphene oxide was fired at 400°C, 450°C, and 500°C, respectively.

[0031] Using SEM, characterize the product after roasting:

[0032] image 3 It is the SEM picture obtained after the copper nitrate and graphene oxide are roasted at ...

Embodiment 3

[0034] Weigh 5 ml of the prepared saturated aqueous solution of copper acetate salt with a measuring cylinder, add it into 0.5 g of graphene oxide obtained after freeze-drying, ultrasonicate for 1 h, and magnetically stir at room temperature for 12 h. After filtering and vacuum drying for 12 hours, a brown cake-like product, that is, a graphene-loaded copper salt product, was obtained. Fully grind the brown cake-like product, weigh 1 g of the product in a quartz boat, put it into a tube furnace to set the temperature, and pass in an inert gas protection, and heat up and roast for 3 hours. In this experiment, the distribution and size of copper nanoparticles obtained by calcination of copper acetate as a copper salt precursor and graphene oxide at 400°C, 450°C, and 500°C were investigated.

[0035] Using SEM, characterize the product after roasting:

[0036] Figure 4 It is the SEM picture obtained after the copper acetate and graphene oxide are roasted at different roasting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com