Humic acid biological fertilizer and preparation method thereof

A humic acid and bio-fertilizer technology, applied in the field of humic acid bio-fertilizer and its preparation, can solve the problems of affecting the health of users, polluting the environment and ecological environment, and deteriorating the soil properties of cultivated land, so as to achieve the goal of being suitable for industrial production and nutrition. The effect of rich elements and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In addition, the scheme of the present application also provides a method for preparing the above-mentioned humic acid bio-fertilizer. In some embodiments, the above-mentioned preparation method includes the following steps: mixing humic acid, biological agent, auxin, cell division Vitamins, active small peptides, potassium dihydrogen phosphate, potassium sulfate, urea, borax and microencapsulated enzymes.

[0047] In some preferred embodiments, the above-mentioned preparation method can first mix humic acid, auxin, cytokinin, active small peptide, potassium dihydrogen phosphate, potassium sulfate, urea and borax, and then mix it with the biological agent, Fermented and finally mixed with microencapsulated enzymes.

[0048] Mix humic acid, auxin, cytokinin, active small peptide, potassium dihydrogen phosphate, potassium sulfate, urea and borax first, so that the above-mentioned substances can be evenly combined with each other, which is beneficial to the biological agen...

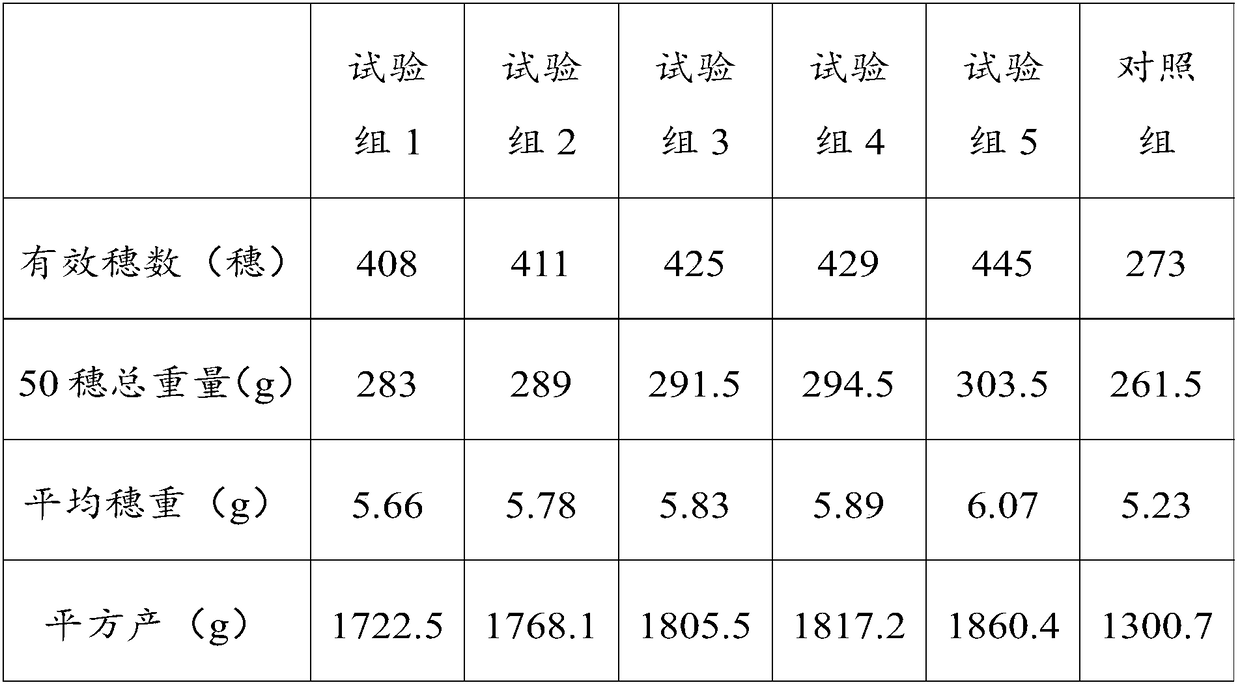

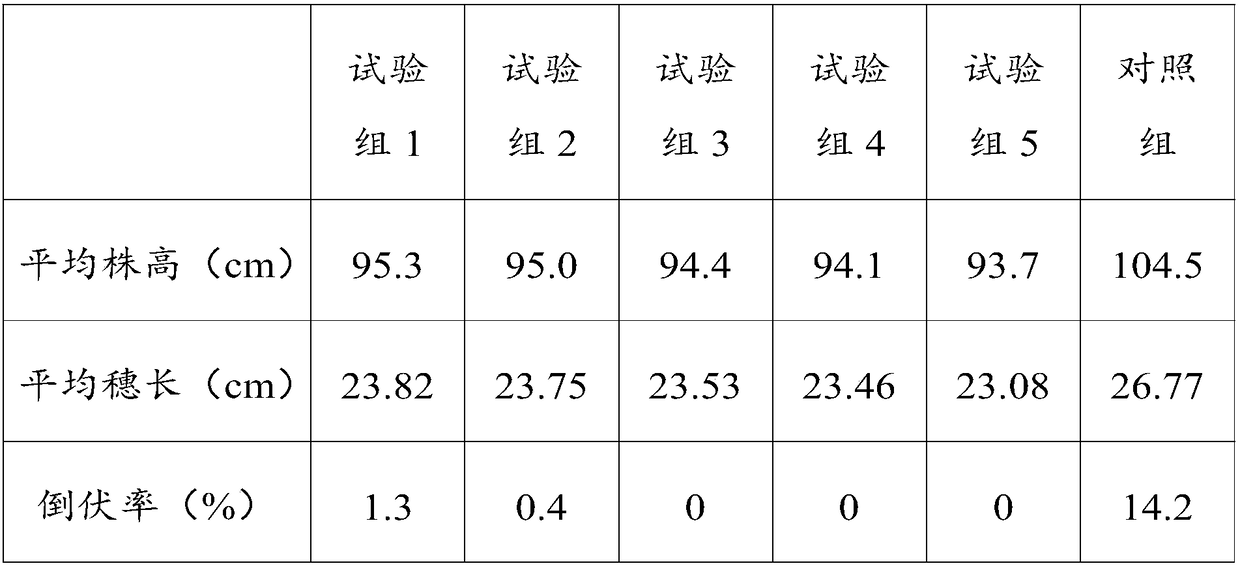

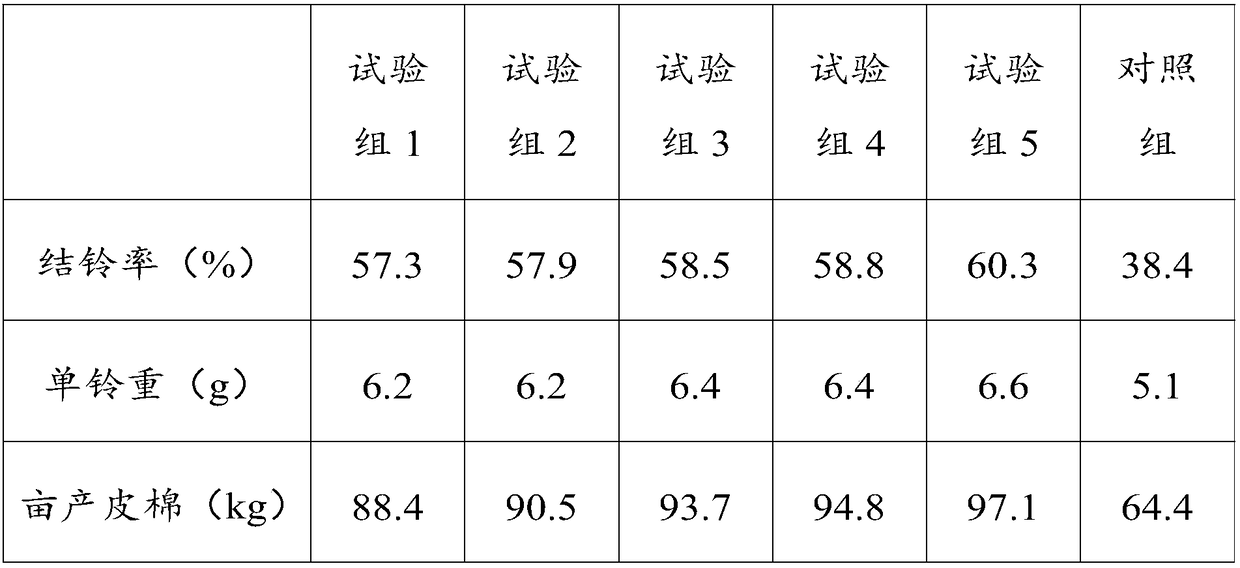

Embodiment 1

[0056] Mix peat and potassium hydroxide solution at a weight ratio of 1:3 for 4 hours at a stirring rate of 100r / min, with a flow rate of 20L / m during the mixing process 3 Continuously feed steam so that the peat and potassium hydroxide solution are always mixed at a temperature of 85° C. to obtain the first mixed solution. Add the first mixed solution to hydrochloric acid at a volume ratio of 100:30, mix, then filter, collect the precipitate, wash, and dry to obtain humic acid containing humic acid and humin.

[0057] Mix nitrate reductase, metalloprotease and antioxidant dismutase at a weight ratio of 2:1:1 to obtain a compound enzyme, inject the compound enzyme into a round capsule with a particle size of 800 μm, and then fill the injection port with a thickness of 5 μm Food glue, get microencapsulated enzyme.

[0058] First mix 4 parts by weight of humic acid, 0.8 parts by weight of auxin, 0.8 parts by weight of cytokinin, 1 part by weight of active small peptide, 18 part...

Embodiment 2

[0061] The difference between this embodiment and Example 1 is that the raw material contains 5 parts by weight of humic acid, 8 parts by weight of biological agent, 1.2 parts by weight of auxin, 1 part by weight of cytokinin, and 1.5 parts by weight of active small peptide, 20 parts by weight of potassium dihydrogen phosphate, 20 parts by weight of potassium sulfate, 14 parts by weight of urea, 0.4 parts by weight of borax and 8 parts by weight of microcapsule enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com