Waterproof plate and preparation method thereof

A body and paint technology, applied in anti-fouling/underwater coatings, sanitary equipment, anti-corrosion coatings, etc., can solve the problems of insufficient strength and toughness, waterproof discs are not wear-resistant, not scratch-resistant, etc., to achieve convenient construction, The effect of good weather resistance and high film hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

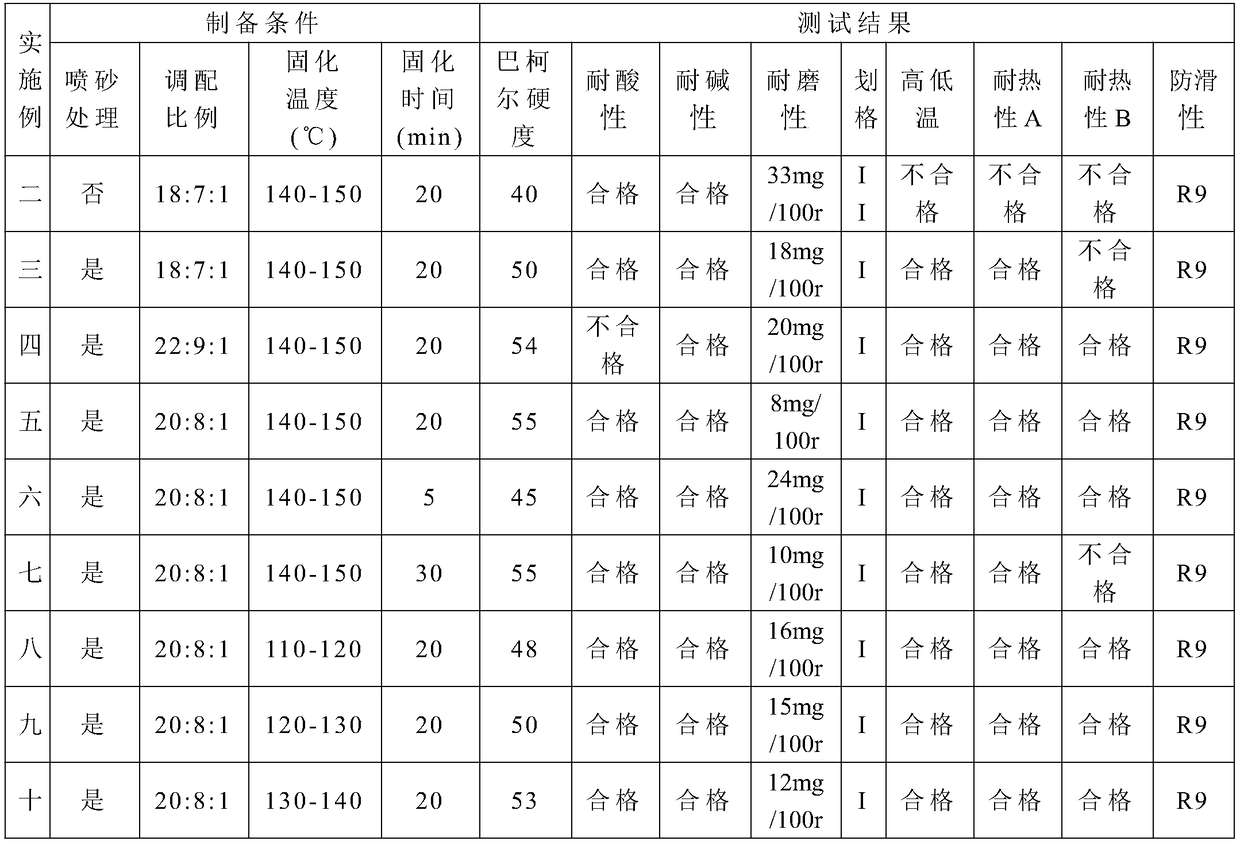

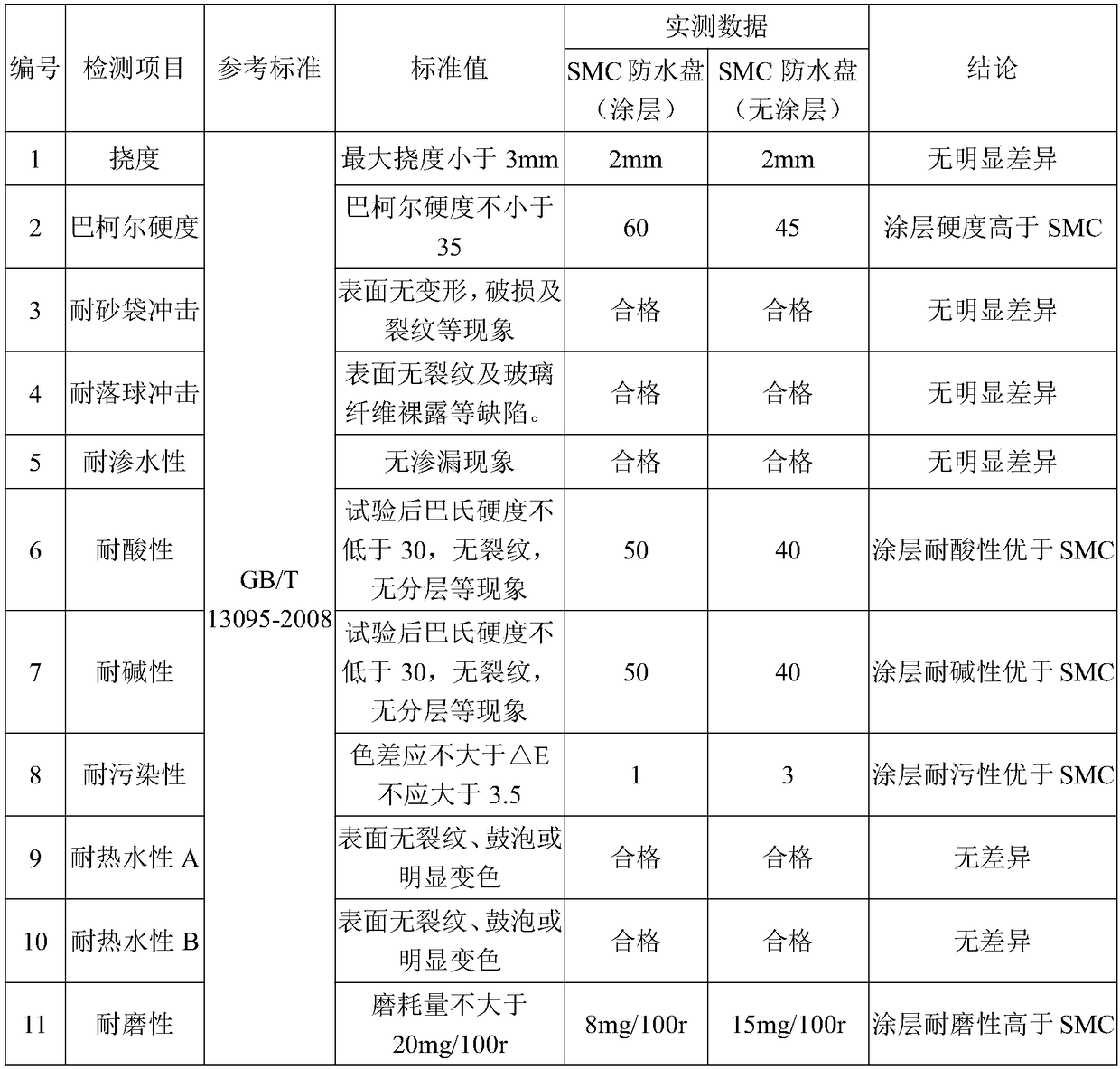

Examples

Embodiment 1

[0038] Example 1 Preparation of nano-ceramic composite coating

[0039] In parts by weight, the nano-ceramic composite coating includes the following components:

[0040] 10 parts of deionized water, 75 parts of inorganic resin, 40 parts of pigment and filler, 2 parts of wetting agent, 3 parts of dispersing agent, 1 part of defoamer, 1 part of film-forming aid, 2 parts of leveling agent, 3 parts of thickener parts, curing agent 1-3 parts and other raw materials.

[0041] The inorganic resin in this embodiment mainly includes silica nano-sol, the wetting agent is polyoxyethylene alkylated ether, the dispersant is acrylic polymer, the defoamer is ethylene oxide, and the film-forming aid is silane The coupling agent (KH-550), the leveling agent is polydimethylsiloxane, the thickener is silicate, and the curing agent is poly-type two-component silicone rubber crosslinking agent (RTV-2).

[0042] The preparation process of silica nano sol is as follows: dissolve ethyl orthosilica...

Embodiment 2

[0052] Use the unsaturated polyester resin SMC waterproof plate with a thickness of 4mm as the base plate, and follow the steps below:

[0053] 1. The surface of the waterproof plate is not sandblasted

[0054] The surface of the waterproof plate in this embodiment is guaranteed to be dry and free from defects such as stains and impurities.

[0055] 2. Paint preparation:

[0056] A deployment ratio (mass ratio):

[0057] Primer (red): diluent: hardener=18:7:1, toner is red toner;

[0058] Sprinkle paint (black dots+white dots): diluent: hardener = 18:7:1, the toner is black and white toner;

[0059] Topcoat (transparent varnish): diluent: hardener = 18:7:1, no pigment;

[0060] The hardener is methyl silane coupling agent, and the diluent is ethylene glycol-ether paint thinner.

[0061] B spraying sequence: primer-sprinkling paint-finish, clean the spray gun repeatedly with acetone after each spraying.

[0062] 3. Surface spraying:

[0063] Primer spraying: Filter the p...

Embodiment 3

[0070] Use the unsaturated polyester resin SMC waterproof plate with a thickness of 4mm as the base plate, and follow the steps below:

[0071] 1. Sand blasting treatment on the surface of the waterproof plate:

[0072] Place the inner surface of the waterproof pan body facing up at 45°, and perform sandblasting and polishing on the inner surface. When sandblasting, the gun head rotates clockwise at a constant speed and moves from left to right until the inner surface of the waterproof disc body is completely polished and rough. After the grinding is completed, use compressed air to clean the residual sand on the surface to ensure that the surface is oil-free, water-free and dry. , No other impurities such as stains, the inner surface of the waterproof plate body is treated and placed horizontally to be sprayed. The sand material used in this embodiment is 120# brown corundum, the working air pressure is 0.6-0.8Mpa, the equipment is a sandblasting machine, and its gun head is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com