A kind of intumescent flame retardant and its preparation method and application

A technology of intumescent flame retardant and silane coupling agent, used in coatings, polyester coatings, fire retardant coatings, etc. Obtain and other problems, to achieve the effect of easy coating and bright appearance, excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

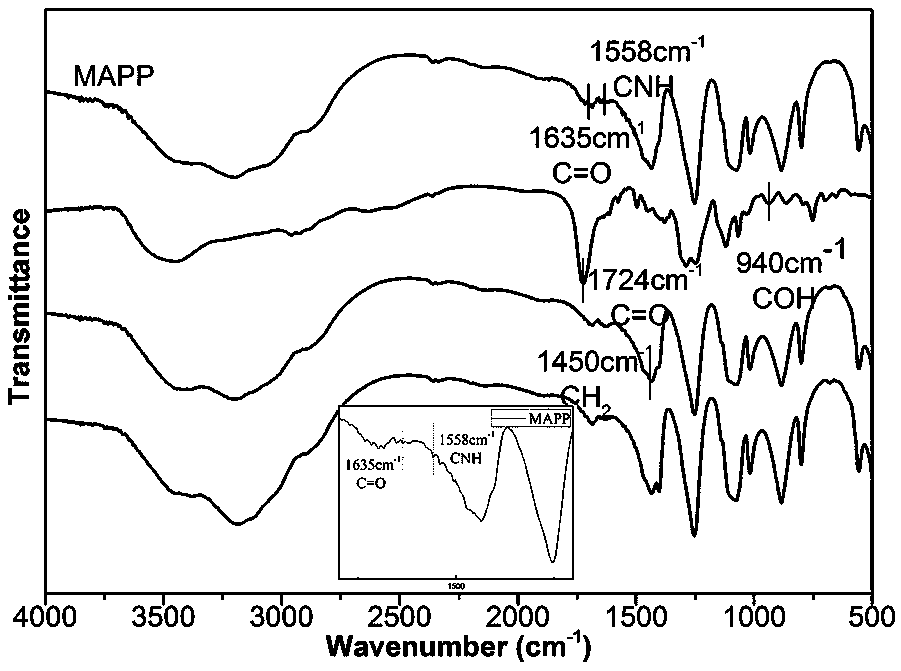

Method used

Image

Examples

Embodiment 1

[0049]First, at a temperature of 80° C., 40 parts of ammonium polyphosphate were ultrasonically dispersed in 150 parts of absolute ethanol, and then poured into a single-necked flask for magnetic stirring. Then add 1 part of silane coupling agent dropwise to 10 parts of absolute ethanol, then add 4 parts of glacial acetic acid dropwise to adjust the pH to 3.5, and then dropwise dropwise into the above-mentioned one-necked flask containing ammonium polyphosphate. At a temperature of 75° C., after fully stirring at a speed of 300 r / min for 2 h, the crude product of ammonium polyphosphate modified by a silane coupling agent was obtained. Then the above-mentioned crude product was suction-filtered, washed several times with absolute ethanol, and dried overnight at 80° C. to obtain a pure product. Dissolve 15 parts of hyperbranched polyester (char-forming agent) in the solvent, add 1 part of catalyst, pour it into a three-necked flask, react at room temperature for half an hour, ta...

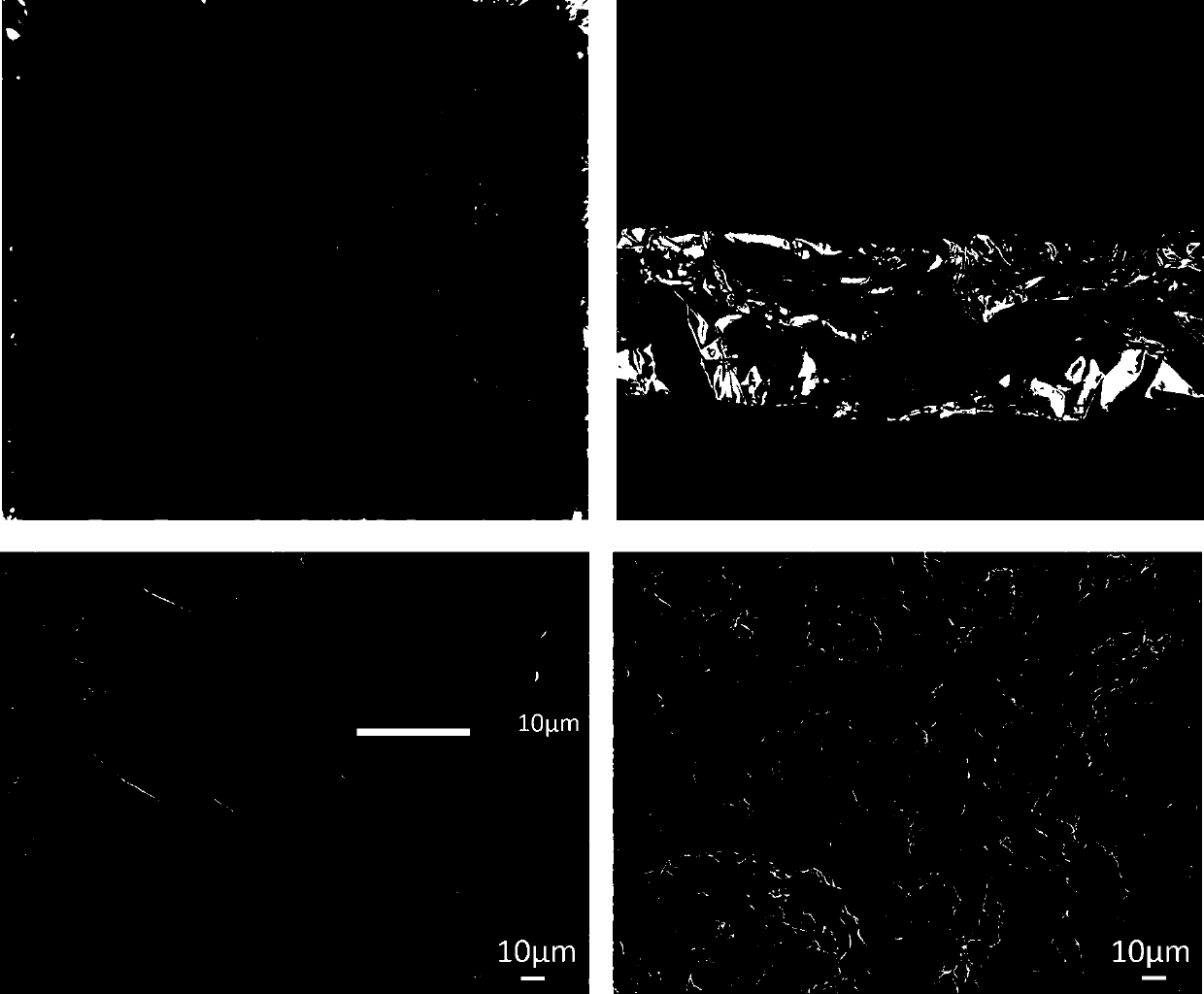

Embodiment 2

[0055] The modified ammonium polyphosphate prepared in Example 1 was used.

[0056] First, add 50 parts of ethanol to the beaker, add 2.5 parts of hyperbranched polyester (char-forming agent, film-forming agent) under the condition of magnetic stirring and heating until it is completely dissolved, then slowly add polyvinyl formaldehyde in small amounts After adding 1 part of aldehyde, keep stirring at high speed for 10 minutes until the solution is transparent. Under the situation that temperature is 130 ℃, add 3.75 parts of modified ammonium polyphosphates successively again. And fully stirred at the speed of 500-600r / min for 5 minutes to obtain a uniformly dispersed emulsion. At this speed and temperature of 130°C, stop heating and stirring until the solution reaches a viscous state. Then take the polypropylene sample strip and place it in the magnetron sputtering equipment. According to 0.5h. Finally, this viscous coating was applied to the magnetron sputtered polypropy...

Embodiment 3

[0058] The modified ammonium polyphosphate prepared in Example 1 was used.

[0059] First, add 50 parts of ethanol to the beaker, add 3 parts of hyperbranched polyester (char-forming agent, film-forming agent) under the condition of magnetic stirring and heating until it is completely dissolved, then slowly add polyvinyl formal After adding 1 part of aldehyde, keep stirring at high speed for 10 minutes until the solution is transparent. When the temperature is 130°C, add 3 parts of modified ammonium polyphosphate successively. And fully stirred at the speed of 500-600r / min for 5 minutes to obtain a uniformly dispersed emulsion. At this speed and temperature of 130°C, stop heating and stirring until the solution reaches a viscous state. Then take the polypropylene sample strip and place it in the magnetron sputtering equipment. According to 0.5h. Finally, this viscous coating was applied to the magnetron sputtered polypropylene strip. This example is referred to as sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com