Anode material for aluminum-air cell and preparation method thereof

An aluminum-air battery and anode material technology, which is applied to battery electrodes, fuel cell-type half-cells, primary cell-type half-cells, circuits, etc. It can improve the electrochemical activity, slow down the self-corrosion of hydrogen evolution, and reduce the self-corrosion of hydrogen evolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

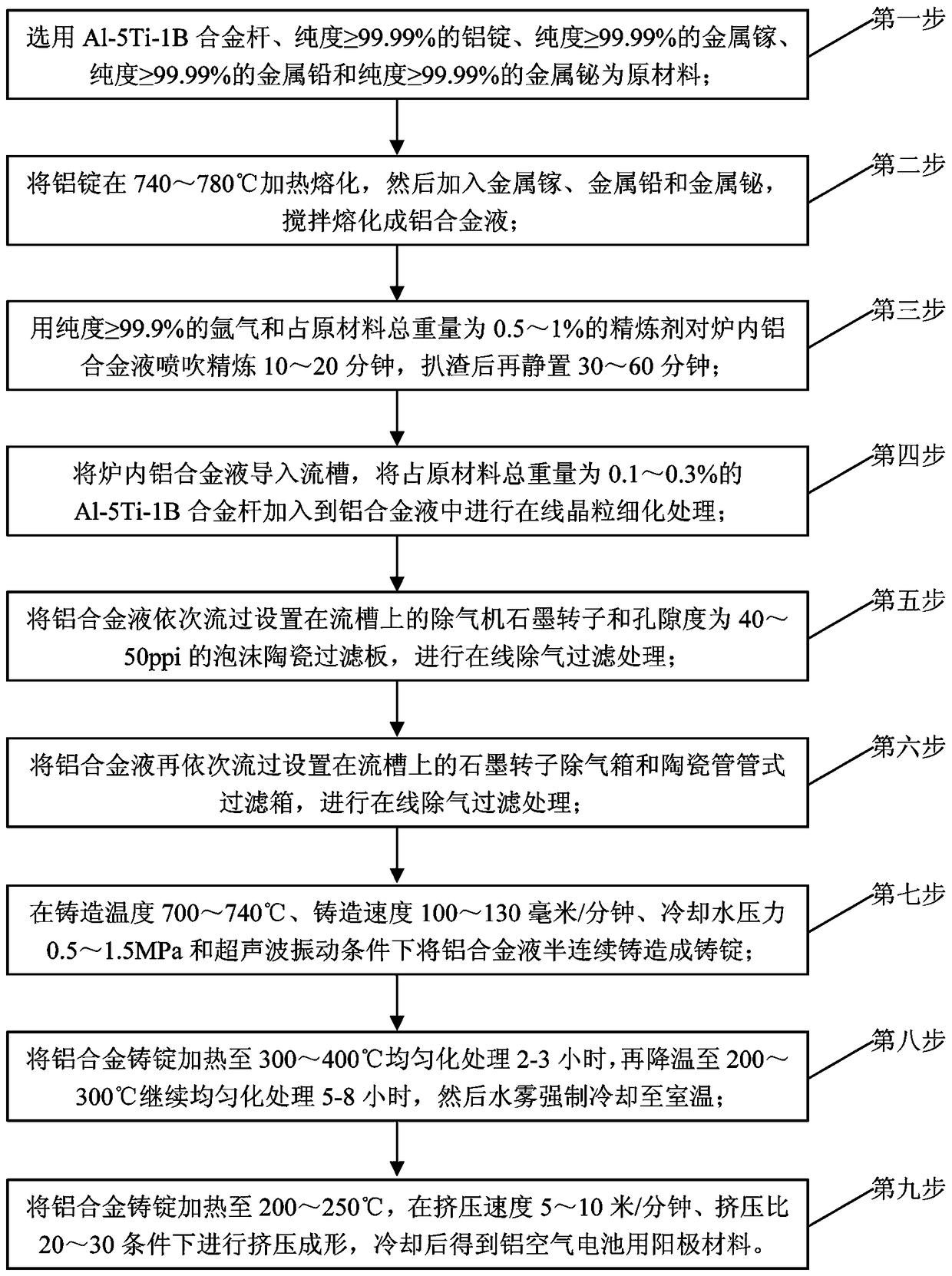

[0033] Please refer to the attached figure 1 , the preparation method of aluminum-air battery anode material of the present invention, comprises the following steps:

[0034] Step 1: Select Al-5Ti-1B alloy rod, aluminum ingot with purity ≥99.99%, gallium metal with purity ≥99.99%, lead metal with purity ≥99.99%, and bismuth metal with purity ≥99.99% as raw materials;

[0035] The higher the purity of the main raw materials aluminum ingots, metal gallium, metal lead and metal bismuth, the higher the electrochemical activity of the aluminum alloy anode material and the lower the self-corrosion rate. The present invention selects aluminum ingots with a purity ≥ 99.99%, gallium metal with a purity ≥ 99.99%, lead metal with a purity ≥ 99.99%, and bismuth metal with a purity ≥ 99.99% as the main raw materials to eliminate Fe, Si, Cu and other metal impurity elements as much as possible. Negative impact on anode material. But it should be understood that the higher the purity of ra...

Embodiment 1

[0052] The anode material for aluminum-air batteries consists of the following components in mass percentage: Ga 0.15%, Pb 0.09%, Bi 0.03%, Ti 0.01%, B 0.002%, Fe 0.002%, Si 0.001%, Cu 0.002%, and the balance is Al and other unavoidable impurities, the individual content of other impurities is ≤0.002%. The preparation method comprises the following steps:

[0053] The first step: select Al-5Ti-1B alloy rod, aluminum ingot with a purity of 99.99%, metal gallium with a purity of 99.99%, metal lead with a purity of 99.99% and metal bismuth with a purity of 99.99% as raw materials;

[0054] Step 2: Heat and melt the aluminum ingot at 760°C in a heating furnace, then add 0.15% metal gallium, 0.09% metal lead and 0.03% metal bismuth to the total weight of the raw materials, stir and melt to form an aluminum alloy liquid;

[0055] The third step: use argon gas with a purity of 99.9% and a hexachloroethane refining agent accounting for 0.8% of the total weight of the raw materials to...

Embodiment 2

[0063]Anode materials for aluminum-air batteries are composed of the following mass percentages: Ga 0.1%, Pb 0.15%, Bi 0.05%, Ti 0.005%, B 0.001%, Fe 0.001%, Si 0.001%, Cu 0.003%, and the balance is Al And unavoidable other impurities, the individual content of other impurities is ≤0.002%. The preparation method comprises the following steps:

[0064] The first step: select Al-5Ti-1B alloy rod, aluminum ingot with a purity of 99.99%, metal gallium with a purity of 99.99%, metal lead with a purity of 99.99% and metal bismuth with a purity of 99.99% as raw materials;

[0065] Step 2: Heat and melt the aluminum ingot at 740°C in a heating furnace, then add 0.1% metal gallium, 0.15% metal lead and 0.05% metal bismuth to the total weight of the raw materials, stir and melt to form an aluminum alloy liquid;

[0066] Step 3: Use argon gas with a purity of 99.9% and a hexachloroethane refining agent accounting for 1% of the total weight of the raw materials to spray and refine the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge current density | aaaaa | aaaaa |

| Self-corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com