Detection method for content of tyramine in soy sauce

A detection method, tyramine technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult operation, cumbersome processing steps, long analysis time, etc., achieve low detection limit, simple and reliable method, and short analysis time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

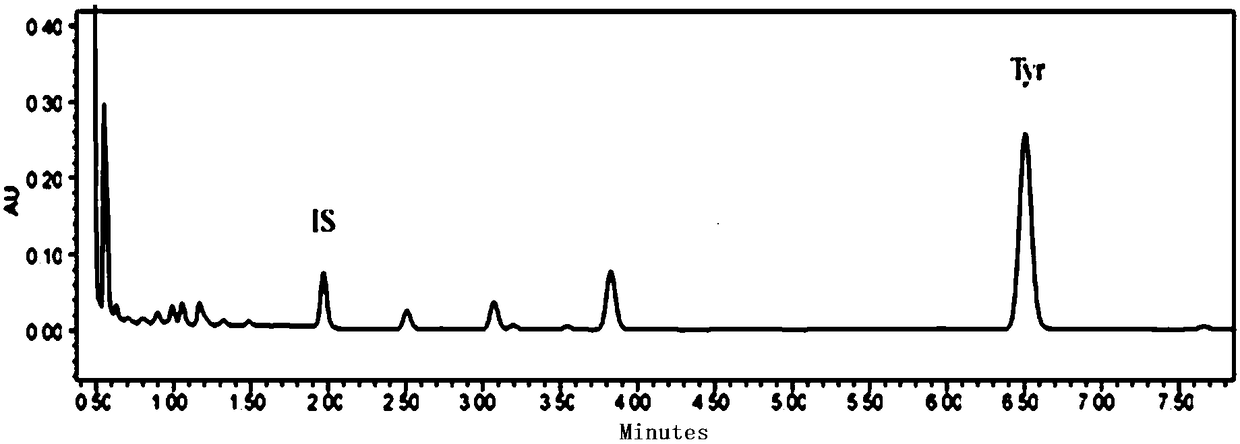

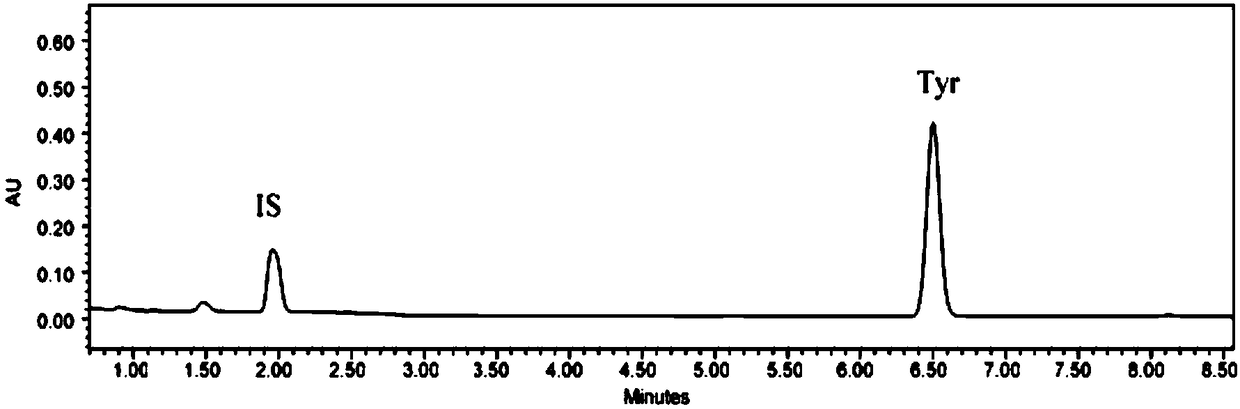

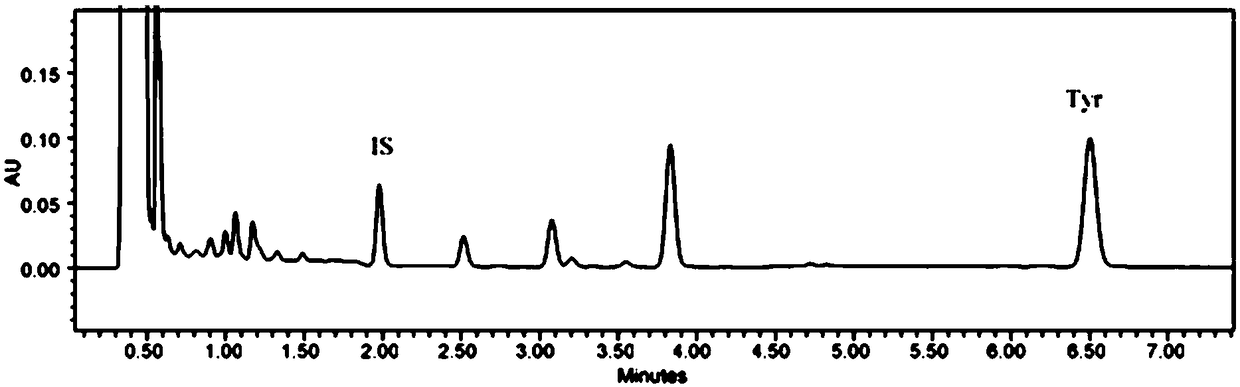

Image

Examples

Embodiment 1

[0021] (a) Pretreatment of the sample solution: 5 mL of the soy sauce sample to be tested was diluted 10 times with deionized water, filtered through a 0.22 μm microporous membrane, and the filtrate was stored at 4° C. for future use.

[0022] (b) Derivatization reaction of the sample: take 100 μL sample from the filtrate, add 50 μg·mL -1 100 μL of internal standard solution, then add 100 μL of saturated sodium bicarbonate with sodium hydroxide to adjust the pH value to 10, and 8 mg·mL prepared with acetone -1 200 μL of dansyl chloride was derivatized at 55°C in the dark for 15 minutes. After the end, 100 μL of ammonia water was added to stop the reaction for 25 min. Add acetonitrile to make up to 1mL. Filter with a microporous membrane of 0.22 μm, and put the filtrate on the column for detection.

[0023] (c) UPLC detection conditions: Waters AcquityⅠ-Class ultra-high performance liquid chromatography, C18, 2.1×50mm, 1.7μm chromatographic column, mobile phase is deionized ...

Embodiment 2

[0028] (a) Pretreatment of the sample solution: 2 mL of the soy sauce sample to be tested was diluted 20 times with deionized water, filtered through a 0.22 μm microporous membrane, and the filtrate was stored at 4° C. for later use.

[0029] (b) Derivatization reaction of the sample: take 100 μL sample from the filtrate, add 50 μg·mL -1 100 μL of internal standard solution, then add 100 μL of saturated sodium bicarbonate with sodium hydroxide to adjust the pH value to 10, and 5 mg·mL of acetone -1 200 μL of dansyl chloride was used for derivatization reaction at 50° C. in the dark for 20 minutes. After the end, 100 μL of ammonia water was added to stop the reaction for 30 min. Add acetonitrile to make up to 1mL. Filter with a microporous membrane of 0.22 μm, and put the filtrate on the column for detection.

[0030] (c) UPLC detection conditions: Waters AcquityⅠ-Class ultra-high performance liquid chromatography, C18, 2.1×50mm, 1.7μm chromatographic column, mobile phase is...

Embodiment 3

[0035] (a) Pretreatment of the sample solution: 10 mL of the soy sauce sample to be tested was diluted 5 times with deionized water, filtered through a 0.22 μm microporous membrane, and the filtrate was stored at 4° C. for later use.

[0036] (b) Derivatization reaction of the sample: take 100 μL sample from the filtrate, add 50 μg·mL -1 100 μL of internal standard solution, then add 100 μL of saturated sodium bicarbonate with sodium hydroxide to adjust the pH value to 10, and 10 mg·mL prepared with acetone -1 200 μL of dansyl chloride was derivatized at 60°C in the dark for 10 minutes. After the end, 100 μL of ammonia water was added to terminate the reaction for 20 min. Add acetonitrile to make up to 1mL. Filter with a microporous membrane of 0.22 μm, and put the filtrate on the column for detection.

[0037] (c) UPLC detection conditions: Waters AcquityⅠ-Class ultra-high performance liquid chromatography, C18, 2.1×50mm, 1.7μm chromatographic column, mobile phase is deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com