Preparation method for porous active silica gel

A porous silica gel and active technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of poor adsorption performance, achieve good adsorption performance, increase the surface area of adsorption, and reduce particle size. small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing porous active silica gel, specifically comprising the following steps:

[0028] ① Grinding magnesium oxide, cobalt chloride and calcium chloride through a 200-mesh sieve respectively, and then preparing solutions with a concentration of 1mol / L with deionized water for subsequent use;

[0029] ②According to the number of parts by weight, take 3 parts of surfactant and add deionized water to prepare a 0.1mol / L surfactant solution, then mix with 20 parts of absolute ethanol and 15 parts of sodium silicate in turn, and stir until mixed It is enough that there is no precipitation in the solution; then the mixed solution is heated in a water bath to a temperature of 40°C, and under magnetic stirring, 15 parts of 0.5 mg / L ammonium chloride solution is added dropwise, and the dropping speed is controlled at 1ml / min. Raise the temperature of the reaction system from 40°C to 50°C, then add 2 parts of 1mol / L magnesium oxide solution and stir for 40 minutes, ...

Embodiment 2

[0034] A method for preparing porous active silica gel, specifically comprising the following steps:

[0035] ① Grinding magnesium oxide, cobalt chloride and calcium chloride through a 200-mesh sieve respectively, and then preparing solutions with a concentration of 1mol / L with deionized water for subsequent use;

[0036] ②According to parts by weight, take 5 parts of surfactant and add deionized water to prepare 0.1mol / L surfactant solution, then mix with 30 parts of absolute ethanol and 20 parts of sodium silicate in turn, and stir until mixed There is no precipitation in the solution; then the mixed solution is heated in a water bath to a temperature of 40°C, and 40 parts of 0.5 mg / L ammonium chloride solution is added dropwise under magnetic stirring, and the dropping speed is controlled at 1ml / min. Raise the temperature of the reaction system from 40°C to 50°C, then add 3 parts of 1mol / L magnesium oxide solution and stir for 40 minutes, then lower the temperature from 50°...

Embodiment 3

[0041] A method for preparing porous active silica gel, specifically comprising the following steps:

[0042] ① Grinding magnesium oxide, cobalt chloride and calcium chloride through a 200-mesh sieve respectively, and then preparing solutions with a concentration of 1mol / L with deionized water for subsequent use;

[0043] ②According to parts by weight, take 4 parts of surfactant and add deionized water to prepare 0.1mol / L surfactant solution, then mix with 25 parts of absolute ethanol and 16.5 parts of sodium silicate in turn, and stir until mixed It is enough that there is no precipitation in the solution; then the mixed solution is heated in a water bath to a temperature of 40°C, and under magnetic stirring, 33 parts of 0.5 mg / L ammonium chloride solution is added dropwise, and the dropping speed is controlled at 1ml / min. Raise the temperature of the reaction system from 40°C to 50°C, then add 2.5 parts of 1mol / L magnesium oxide solution and stir for 40 minutes, then lower t...

PUM

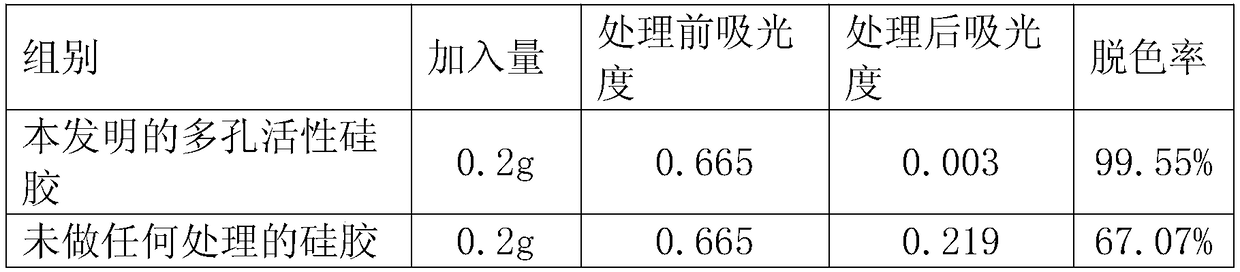

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com