A kind of calcium chloride wastewater treatment process

A wastewater treatment and calcium chloride technology, applied in the direction of backflow water treatment, natural water treatment, multi-stage water treatment, etc., can solve the cost of increasing packaging materials, labor, energy consumption, calcium chloride product backlog, calcium chloride Problems such as large amount of waste water, to achieve the effect of low cost, improved purity, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

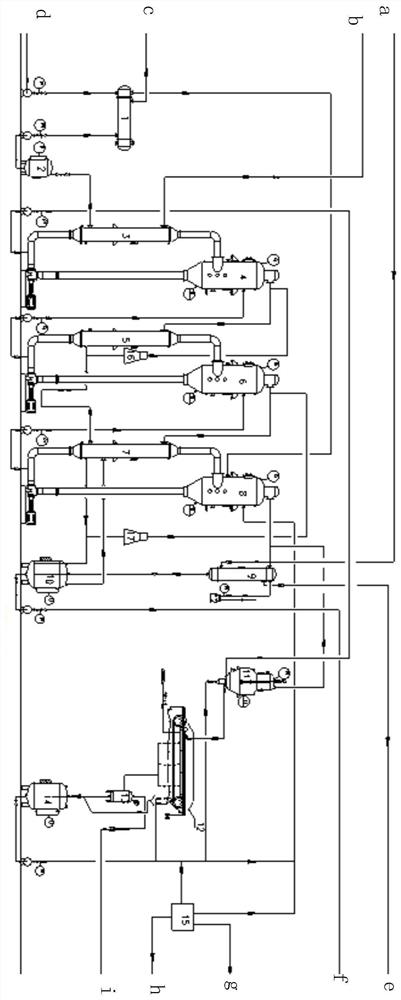

[0036] like figure 1 As shown, a calcium chloride wastewater treatment process, wherein the wastewater comes from the wastewater produced by the fly ash aluminum industry, the specific process steps are firstly using a three-effect multi-stage evaporator to treat the calcium chloride wastewater to obtain primary wastewater, namely chlorination Calcium waste water (raw material liquid) enters the raw steam condensate preheater 1 through the feeding pump for preheating, and then enters the three-effect separation chamber 8, the three-effect heating chamber 7, and the second-effect separation chamber 6 in turn after the temperature is preheated to 88°C Carry out evaporative concentration with two-effect heating chamber 5, one-effect separation chamber 4 and one-effect heating chamber 3, and the concentration of calcium chloride waste water is raised to 48% by 20%. Among them, the liquid phase temperatures of the three-effect separation chamber 8, the second-effect separation cham...

Embodiment 2

[0041] like figure 1 As shown, a calcium chloride wastewater treatment process, wherein the wastewater comes from the wastewater produced by the fly ash aluminum industry, the specific process steps are firstly using a three-effect multi-stage evaporator to treat the calcium chloride wastewater to obtain primary wastewater, namely chlorination Calcium waste water (raw material liquid) enters the raw steam condensate preheater 1 through the feeding pump for preheating, and then enters the three-effect separation chamber 8, the three-effect heating chamber 7, and the second-effect separation chamber 6 in turn after the temperature is preheated to 92°C Carry out evaporation and concentration with the second-effect heating chamber 5, the first-effect separation chamber 4 and the first-effect heating chamber 3, and the concentration of the calcium chloride wastewater increases from 21% to 49%. Among them, the liquid phase temperatures of the three-effect separation chamber 8, the s...

Embodiment 3

[0046] like figure 1 As shown, a calcium chloride wastewater treatment process, wherein the wastewater comes from the wastewater produced by the fly ash aluminum industry, the specific process steps are firstly using a three-effect multi-stage evaporator to treat the calcium chloride wastewater to obtain primary wastewater, namely chlorination Calcium waste water (raw material liquid) enters the raw steam condensate preheater 1 through the feeding pump for preheating, and then enters the three-effect separation chamber 8, the three-effect heating chamber 7, and the second-effect separation chamber 6 after the temperature is preheated to 90°C Carry out evaporative concentration with two-effect heating chamber 5, one-effect separation chamber 4 and one-effect heating chamber 3, and the concentration of calcium chloride waste water is raised to 50% by 22%. Among them, the liquid phase temperatures of the three-effect separation chamber 8, the second-effect separation chamber 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com