A kind of purification method of methylene blue

A purification method and methylene blue technology, applied in the direction of organic chemistry, etc., can solve the problems of difficult quality control of high-purity methylene blue, and achieve the effect of general and easy method, large operation plasticity and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

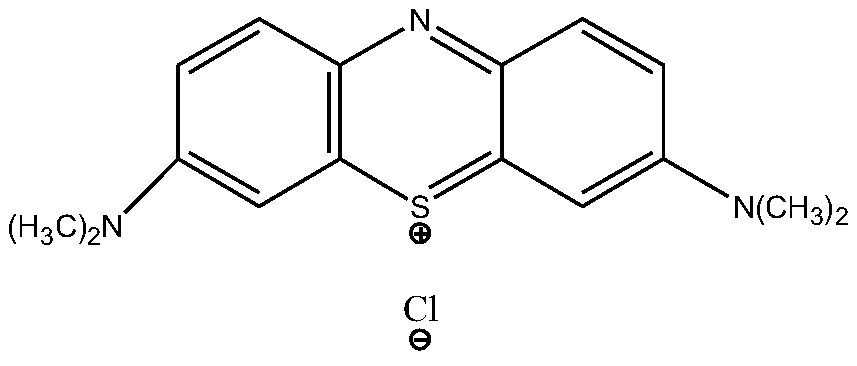

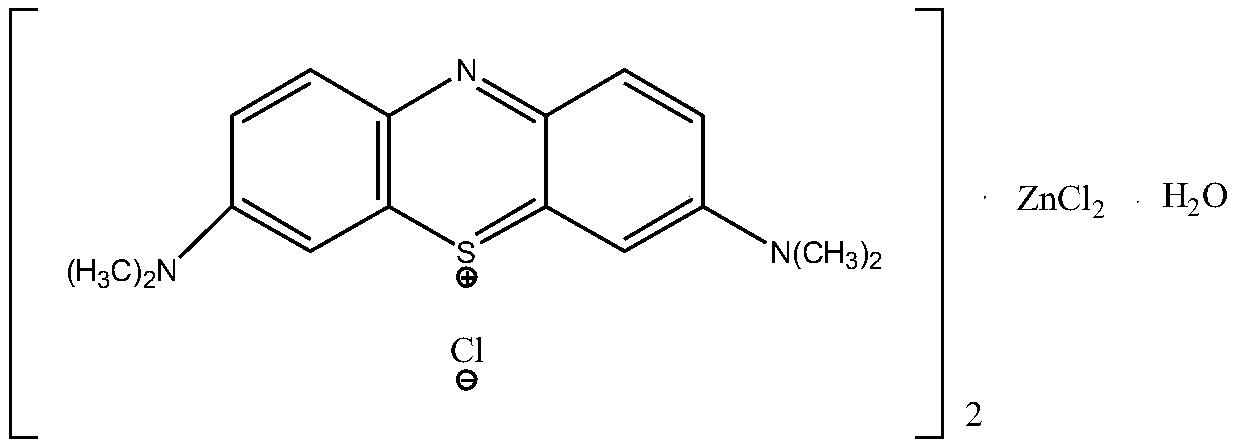

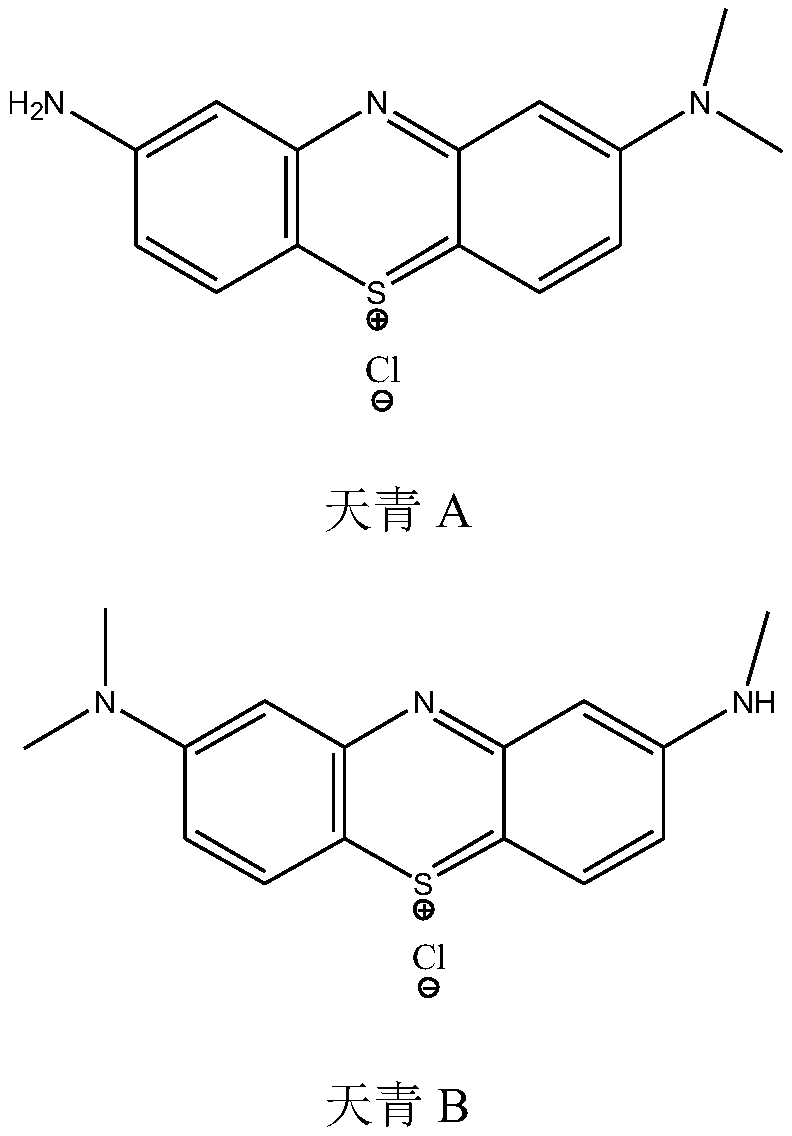

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A purification method of methylene blue:

[0030] Add 150g of raw salt-based lake blue BB, add 2250g of water, and when heated to 60~90℃, gradually add a mixed solution of sodium bicarbonate and sodium carbonate under stirring (40g sodium bicarbonate plus 0.8g sodium carbonate, dissolved in 500ml water), Control the pH of the reaction solution at 7.5-9, add it in about 30 minutes, keep it for 30 minutes, and pass it into the crystallization tank through a filter. 75 g of hydrochloric acid was added to the filtrate, and after stirring for 15 minutes, it was allowed to cool to precipitate bright dark green crystals. The crystals were centrifuged and dried to obtain 64.1 g of methylene blue, the content was greater than or equal to 98.5%, and the yield was 90.7%. The results meet the requirements of the Pharmacopoeia and are far higher than the analytical methylene blue content index.

Embodiment 2

[0032] A purification method of methylene blue:

[0033] Add 150g of raw salt-based lake blue BB, add 1950g of water, and when heated to 60~90℃, gradually add a mixed solution of sodium bicarbonate and sodium carbonate under stirring (40g sodium bicarbonate plus 0.04g sodium carbonate, dissolved in 500ml water), Control the pH of the reaction solution at 7.5-9, add it in about 30 minutes, keep it warm for 60 minutes, and enter the crystallization tank through a filter. 60 g of hydrochloric acid was added to the filtrate, and after stirring for 15 minutes, it was allowed to cool to precipitate bright dark green crystals. The crystals are centrifuged and dried to obtain 63.6 g of methylene blue, the content is greater than or equal to 98.6%, and the yield is 90%. The results meet the requirements of the Pharmacopoeia and are far higher than the analytical methylene blue content index.

Embodiment 3

[0035] A purification method of methylene blue:

[0036] Add 150g of raw salt-based lake blue BB, add 2400g of water, and when heated to 60~90℃, gradually add a mixed solution of sodium bicarbonate and sodium carbonate under stirring (52.5g sodium bicarbonate plus 0.8g sodium carbonate, dissolved in 500ml water) , Control the pH of the reaction solution at 7.5-9, add it in about 30 minutes, keep it for 100 minutes, pass the filter into the crystallization tank. Add 90 g of hydrochloric acid to the filtrate, and after stirring for 15 minutes, it was allowed to cool to precipitate shiny dark green crystals. The crystals were centrifuged and dried to obtain 64.5 g of methylene blue, the content was greater than or equal to 98.5%, and the yield was 91.3%. The results meet the requirements of the Pharmacopoeia and are far higher than the analytical methylene blue content index.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com