Preparation method of electromagnetic shielding elastic material for sealing

A technology of electromagnetic shielding and elastic materials, which is applied in the field of preparation of electromagnetic shielding elastic materials for sealing, can solve the problems of not being able to meet the needs of thermal conductivity and electromagnetic shielding functions, difficult to recycle, and low rebound rate, etc., and achieve good low temperature flexibility , improve the strength, block the effect of continuous decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

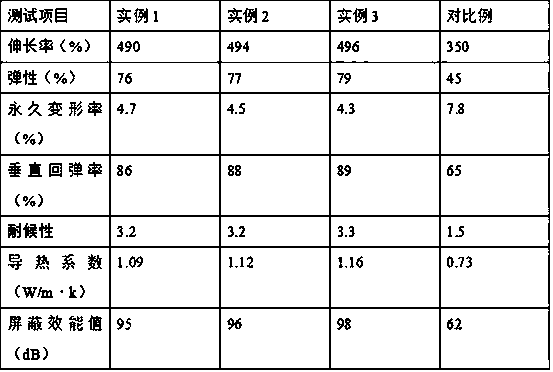

Examples

example 1

[0028] Add 80g of acrylonitrile and 90g of butadiene into a three-necked flask, add 100mL of mass fraction of 5% sodium hydroxide solution, 30g of polyvinyl alcohol, 100mL of 40% of the mass fraction of nano-graphite in the three-necked flask, Start the agitator, stir and emulsify at a speed of 80r / min for 10min, add 1g of potassium persulfate, heat up to 45°C, and keep warm for 3h to obtain nano-reinforced nitrile rubber; add 40g of acrylic acid and maleic anhydride copolymer to the Put 100mL of a beaker with a mass fraction of 30% acetone solution, heat up to 80°C, add 60g of bentonite to the beaker, cool down to room temperature to obtain a bentonite suspension, put the bentonite suspension in a high-speed centrifuge, and centrifuge at a speed of 3100r / min After 15 minutes, remove the supernatant to obtain lamellar bentonite, place the lamellar bentonite in an oven, heat up to 80°C, and dry for 3 hours to obtain modified bentonite; place nano-reinforced nitrile rubber in a d...

example 2

[0030] 85g of acrylonitrile and 100g of butadiene were added in a three-necked flask, and 110mL of a mass fraction of 5% sodium hydroxide solution, 35g of polyvinyl alcohol, and 110mL of a mass fraction of 40% were added to the three-necked flask. Start the agitator, stir and emulsify at a speed of 85r / min for 12min, add 2g of potassium persulfate, heat up to 47°C, and keep the temperature for 3.5h to obtain nano-reinforced nitrile rubber; add 42g of acrylic acid and maleic acid copolymer to the container Put 110mL of acetone solution with a mass fraction of 35% in a beaker, heat up to 82°C, add 65g of bentonite to the beaker, cool down to room temperature to obtain a bentonite suspension, put the bentonite suspension in a high-speed centrifuge at a speed of 3400r / min Centrifuge for 16 minutes, remove the supernatant to obtain sheet-layer bentonite, place the sheet-layer bentonite in an oven, heat up to 85°C, and dry for 3.5 hours to obtain modified bentonite; place nano-reinfo...

example 3

[0032] Add 90g of acrylonitrile and 110g of butadiene into a three-necked flask, add 120mL of mass fraction of 5% sodium hydroxide solution, 40g of polyvinyl alcohol, 120mL of 40% of the mass fraction of nano-graphite in the three-necked flask, Start the agitator, stir and emulsify at a speed of 90r / min for 15min, add 3g of potassium persulfate, heat up to 48°C, and keep warm for 4h to obtain nano-reinforced nitrile rubber; add 45g of acrylic acid and maleic anhydride copolymer to the In a 120mL beaker with a mass fraction of 40% acetone solution, heat up to 85°C, add 70g of bentonite to the beaker, cool down to room temperature to obtain a bentonite suspension, put the bentonite suspension in a high-speed centrifuge, and centrifuge at a speed of 3800r / min 17min, remove the supernatant to obtain lamellar bentonite, place the lamellar bentonite in an oven, heat up to 90°C, and dry for 4 hours to obtain modified bentonite; place nano-reinforced nitrile rubber in a double-roller m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com