Building antifouling coating and method for preparing same

An antifouling coating and construction technology, applied in antifouling/underwater coatings, fireproof coatings, reflection/signal coatings, etc., can solve the problems of poor reflection efficiency, waste of resources, easy to be contaminated with dust, etc., to improve film-forming performance , super adhesion, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

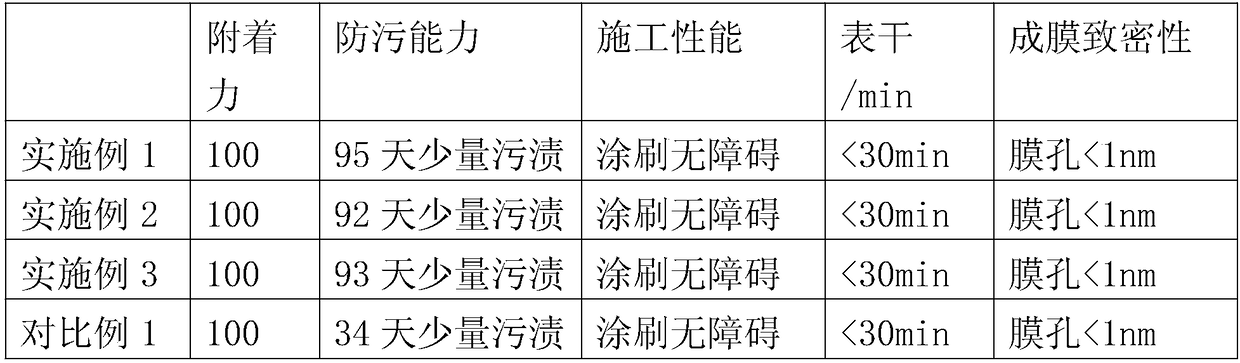

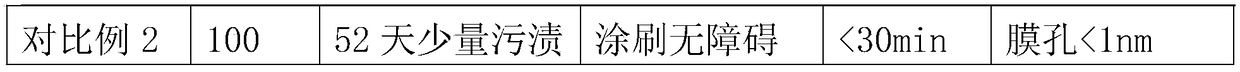

Embodiment 1

[0040] An antifouling paint for construction, comprising the following main components:

[0041] Polyacrylate 16%

[0042] Light Calcium Carbonate 12%

[0043] Titanium dioxide 22%

[0044] Infrared ceramic powder 0.3%

[0045] Hollow ceramic microspheres 1.5%

[0046] Nanoscale antifouling additive 0.03%

[0047] Dispersant 0.25%

[0048] Antifreeze 0.15%

[0049] Thickener 0.8%

[0050] Wetting agent 0.07%

[0051] Defoamer 0.25%

[0052] Coalescing aid 0.7%

[0053] Film-forming catalyst 0.003%

[0054] water balance.

[0055] The particle size of the infrared ceramic powder and hollow ceramic microspheres is 325 mesh.

[0056] Described wetting agent is BASF Hydropalat875.

[0057] The film-forming aid is dodecyl alcohol ester; the film-forming catalyst is cerium oxide.

[0058] The titanium dioxide contains 0.3% titanium dioxide P25.

[0059] The nanoscale antifouling additive is inorganic modified graphene oxide.

[0060] The preparation method of the des...

Embodiment 2

[0069] An antifouling paint for construction, comprising the following main components:

[0070] Polyacrylate 12%

[0071] Light Calcium Carbonate 15%

[0072] Titanium dioxide 15%

[0073] Infrared ceramic powder 0.5%

[0074] Hollow ceramic microspheres 1%

[0075] Nanoscale antifouling additive 0.05%

[0076] Dispersant 0.2%

[0077] Antifreeze 0.3%

[0078] Thickener 0.5%

[0079] Wetting agent 0.1%

[0080] Defoamer 0.2%

[0081] Coalescent 1%

[0082] Film-forming catalyst 0.002%

[0083] water balance.

[0084] The particle size of the infrared ceramic powder and hollow ceramic microspheres is 325 mesh.

[0085] Described wetting agent is BASF Hydropalat875.

[0086] The film-forming aid is dodecyl alcohol ester; the film-forming catalyst is cerium oxide.

[0087] The titanium dioxide contains 0.5% titanium dioxide P25.

[0088] The nanoscale antifouling additive is inorganic modified graphene oxide.

[0089] The preparation method of the described inorgan...

Embodiment 3

[0098] An antifouling paint for construction, comprising the following main components:

[0099] Polyacrylate 18%

[0100] Light Calcium Carbonate 8%

[0101] Titanium dioxide 25%

[0102] Infrared ceramic powder 0.2%

[0103] Hollow ceramic microspheres 3%

[0104] Nanoscale antifouling additive 0.02%

[0105] Dispersant 0.5%

[0106] Antifreeze 0.1%

[0107] Thickener 1%

[0108] Wetting agent 0.05%

[0109] Defoamer 0.4%

[0110] Coalescing aid 0.5%

[0111] Film-forming catalyst 0.005%

[0112] water balance.

[0113] The particle size of the infrared ceramic powder and hollow ceramic microspheres is 325 mesh.

[0114] Described wetting agent is BASF Hydropalat875.

[0115] The film-forming aid is dodecyl alcohol ester; the film-forming catalyst is cerium oxide.

[0116] The titanium dioxide contains 0.1% titanium dioxide P25.

[0117] The nanoscale antifouling additive is inorganic modified graphene oxide.

[0118] The preparation method of the described i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com