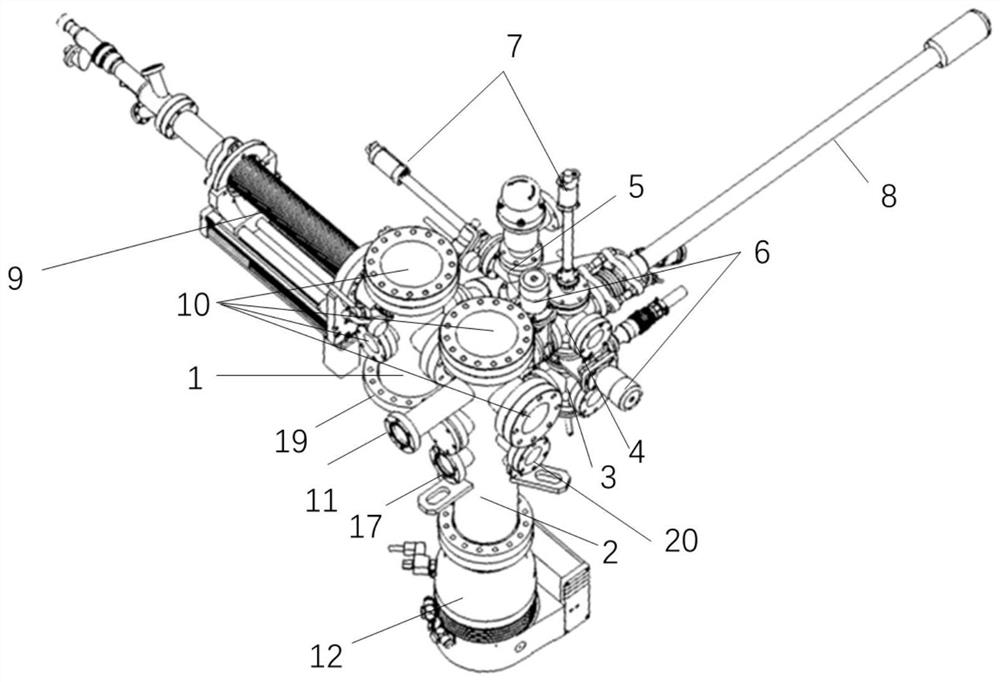

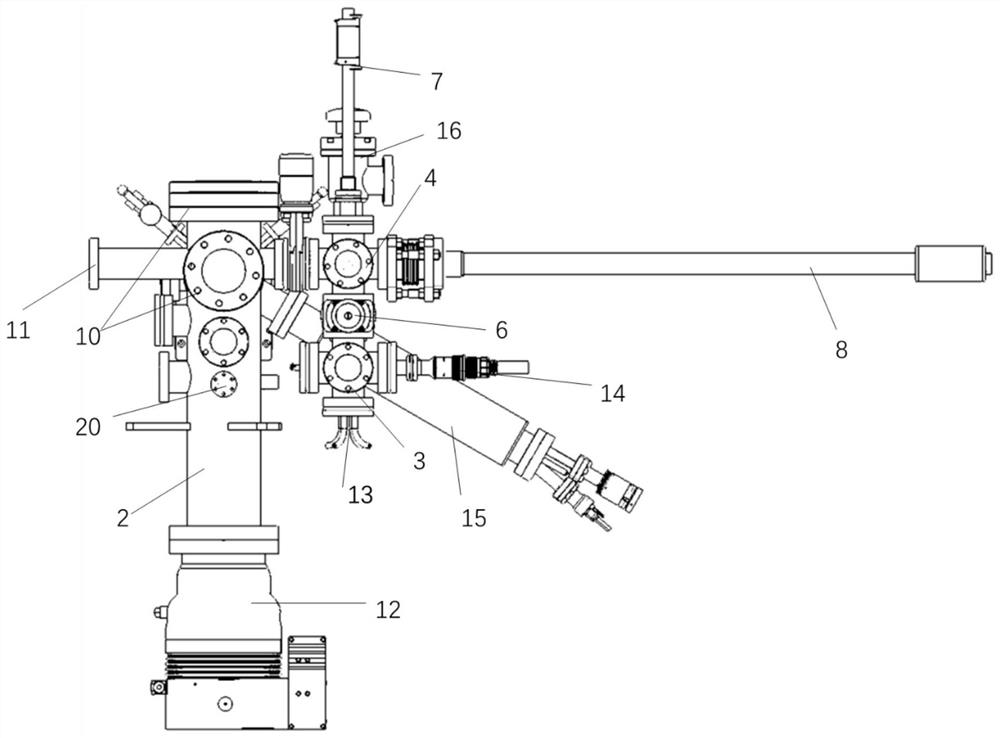

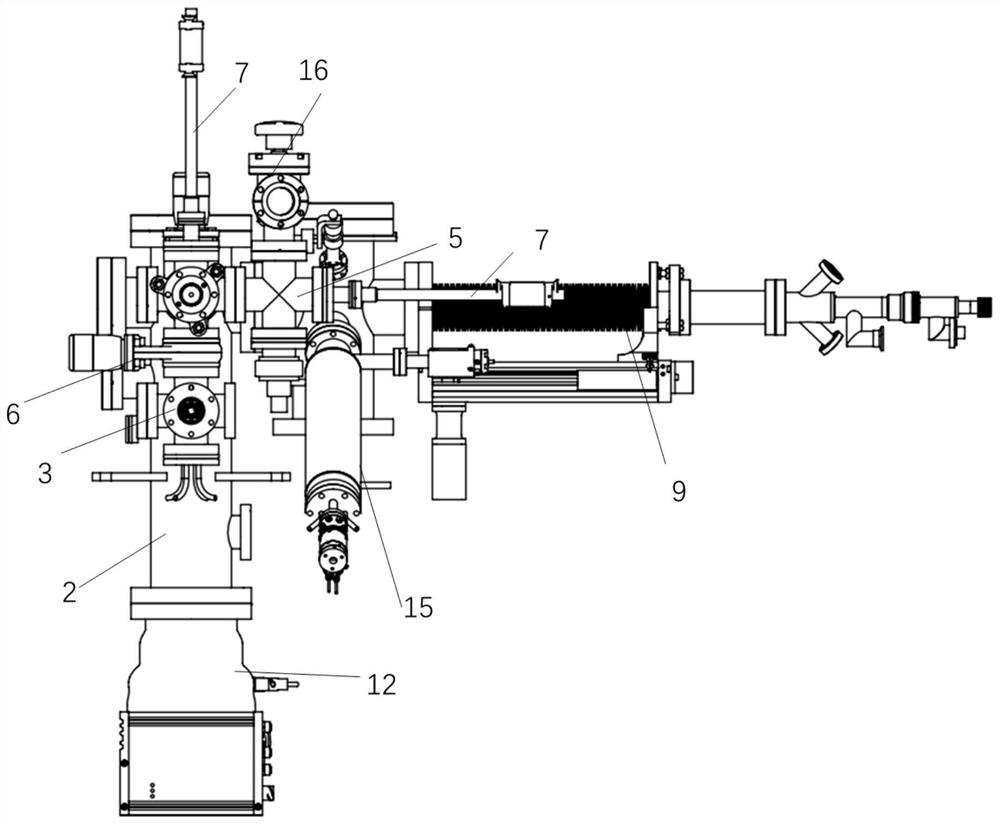

A test device for thin film deposition and catalytic reaction of volatile corrosive substances under ultra-high vacuum conditions

A thin film deposition device and corrosive substance technology, applied in vacuum evaporation plating, chemical analysis by catalysis, coating, etc., can solve the problems of inaccurate activity testing, restricting structure-performance, background pollution, etc., to avoid Pollution and Negative Effects, Achieve Pollution-Free Transfer, Effect of Avoiding Background Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The thin film deposition device based on volatile and corrosive substances under ultra-high vacuum conditions can deposit low-melting point metal Zn oxide ZnO thin film samples, and then transfer them to the ultra-high vacuum system for structural analysis without affecting the ultra-high vacuum system.

[0088] The deposition device based on the volatile sample thin film under ultra-high vacuum condition is connected with the ultra-high vacuum system. Raise the Zn evaporation source to a suitable temperature (~200)°C for degassing. The clean substrate samples (such as Pt(111), Au(111), Cu(111), etc.) prepared in the ultra-high vacuum system can be directly transferred to the growth chamber of the device through the sample transfer rod, and the equipment and the ultra-high Gate valves for vacuum systems. Adjust the position of the substrate sample and the evaporation source through the three-dimensional operation table. Introduce high-purity O through a vacuum leak va...

Embodiment 2

[0090] Based on the thin film deposition device of volatile corrosive substances under ultra-high vacuum conditions, corrosive H 2 MoS in S atmosphere 2 The deposition of thin film samples is then introduced into the ultra-high vacuum system for structural analysis without affecting the ultra-high vacuum system.

[0091] The thin film deposition device for volatile and corrosive substances based on ultra-high vacuum conditions is connected with an ultra-high vacuum system. In the growth chamber, the ion source and Ar can be used to etch the gold single crystal in situ to obtain the Au single crystal substrate that meets the requirements. Raise the Mo source to a suitable temperature (~1800°C) for degassing. Adjust the position of the substrate sample and the evaporation source through the three-dimensional operation table. Inject high-purity H through a vacuum leak valve 2 S(99.999%) to 1×10 -6 mbar, deposited MoS 2 Film to proper coverage. then close H 2 S gas. The c...

Embodiment 3

[0094] In the present invention, based on the catalytic reaction test device under the ultra-high vacuum condition, the catalytic reaction test of the sample in the ultra-high vacuum system under the condition of close to the atmospheric pressure can be carried out, and the reacted sample is then introduced into the ultra-high vacuum system for structural analysis without the need for ultra-high vacuum. The vacuum system is affected. The catalytic reaction test device based on the ultra-high vacuum condition is connected with the ultra-high vacuum system. The clean substrate samples (such as FeO / Pt(111), FeO / Au(111)) prepared in the ultra-high vacuum system can be directly transferred to the reaction chamber through the sample transfer rod, and the connection between the device and the ultra-high vacuum system is closed. Gate valve. Open the gas inlet in the reaction chamber to introduce CO and O at an atmospheric pressure 2 The mixed gas, record the initial reaction gas pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com