Method for preparing cathode material for LiVPO4F lithium-ion batteries by means of double-layer carbon coating

A lithium ion battery, lithium vanadium fluorophosphate technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems to be improved, achieve ultra-stable cycle performance, easy operation, and reduce the effect of grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

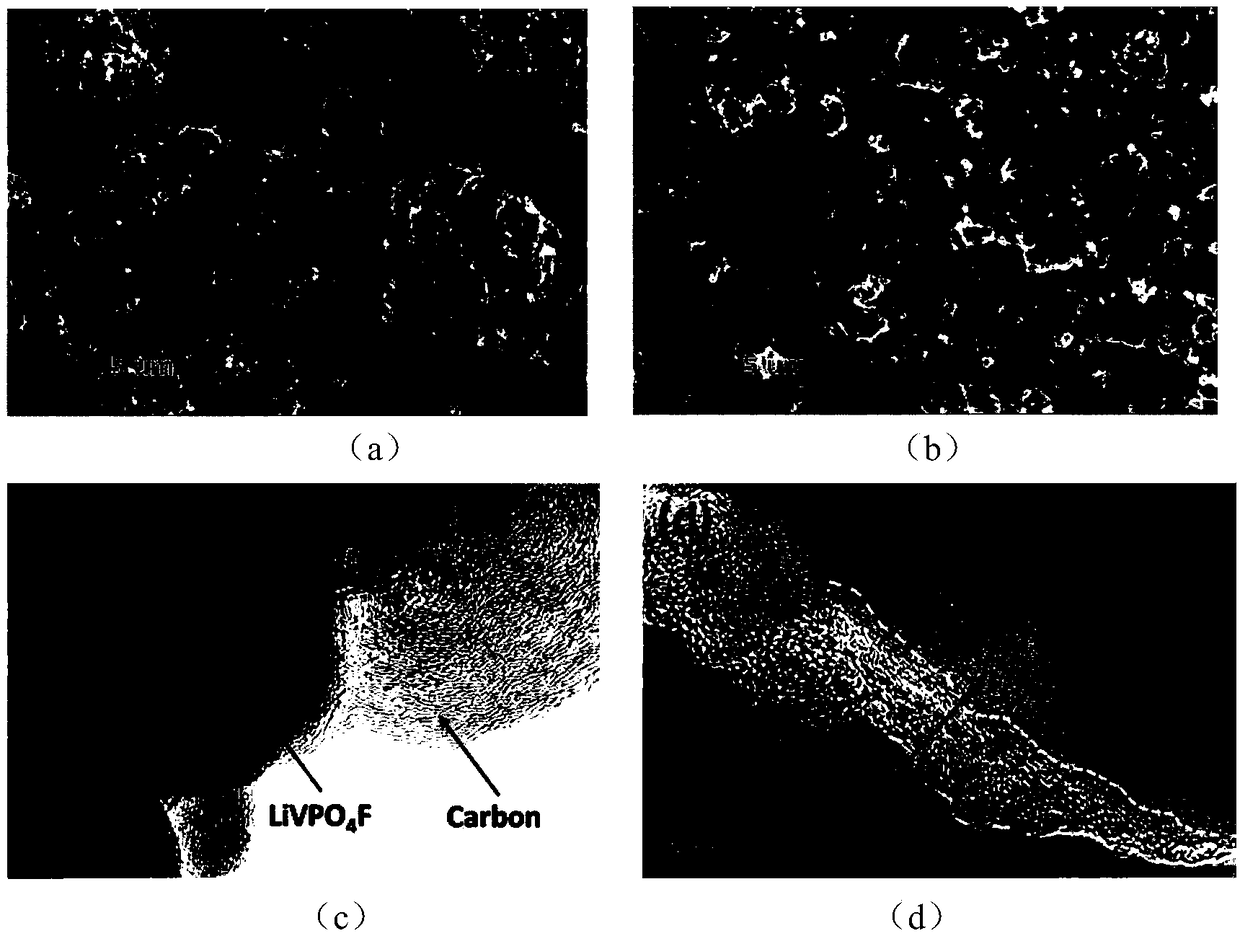

[0030] 1) Mix vanadium salt, carbon source and phosphate source uniformly according to the ratio of V:P molar ratio=1:1, C:P molar ratio=1.5:1, heat treatment at 600°C for 12h under nitrogen atmosphere, then pulverize and grind, Obtain mesophase product;

[0031] 2) Mix the mesophase product, lithium fluoride and carbon source uniformly according to the ratio of Li:V:P:F molar ratio = 1:1:1:1, C:P molar ratio = 0.02:1, and then heat-treat at 800°C 1h, then pulverize and grind, and obtain double-layer carbon coating after sieving to prepare LiVPO 4 F Lithium-ion battery cathode material.

[0032] Vanadium salt is V 2 o 5 .

[0033] The carbon source in step 1) is citric acid.

[0034] The carbon source in step 2) is sucrose.

[0035] The phosphate source is H 3 PO 4 .

Embodiment 2

[0037] 1) Mix vanadium salt, carbon source and phosphate source uniformly according to the ratio of V:P molar ratio=1:1, C:P molar ratio=1.5:1, heat treatment at 800°C for 1h under nitrogen atmosphere, then pulverize and grind, Obtain mesophase product;

[0038] 2) Mix the mesophase product, lithium fluoride and carbon source uniformly according to Li:V:P:F molar ratio = 1:1:1:1, C:P molar ratio = 0.1:1, and then heat-treat at 700°C 3h, then pulverize and grind, and obtain double-layer carbon coating after sieving to prepare LiVPO 4 F Lithium-ion battery cathode material.

[0039] Vanadium salt is V 2 o 3 .

[0040] The carbon source in step 1) is sucrose.

[0041] The carbon source in step 2) is VC.

[0042] Phosphate source is NH 4 h 2 PO 4 .

Embodiment 3

[0044] 1) Mix vanadium salt, carbon source and phosphate source uniformly according to the ratio of V:P molar ratio=1:1, C:P molar ratio=1.5:1, heat treatment at 700°C for 7h under nitrogen atmosphere, then pulverize and grind, Obtain mesophase product;

[0045] 2) Mix the mesophase product, lithium fluoride and carbon source uniformly according to Li:V:P:F molar ratio = 1:1:1:1, C:P molar ratio = 0.15:1, and then heat-treat at 600°C 7h, then pulverize and grind, and obtain double-layer carbon coating after sieving to prepare LiVPO 4 F Lithium-ion battery cathode material.

[0046] Vanadium salt is NH 4 VO 3 .

[0047] The carbon source in step 1) is VC.

[0048] The carbon source in step 2) is glucose.

[0049] The phosphate source is (NH 4 ) 2 HPO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com