Metal-organic framework UiO-66 adsorbent and modified material thereof

A metal-organic framework and modified material technology, which is applied in the fields of alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of poor thermal stability and hydrothermal stability of adsorbents, which cannot meet the requirements of industrial use , Inhomogeneous pore structure and other issues, to achieve good thermal stability and hydrothermal stability, good industrial application prospects, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

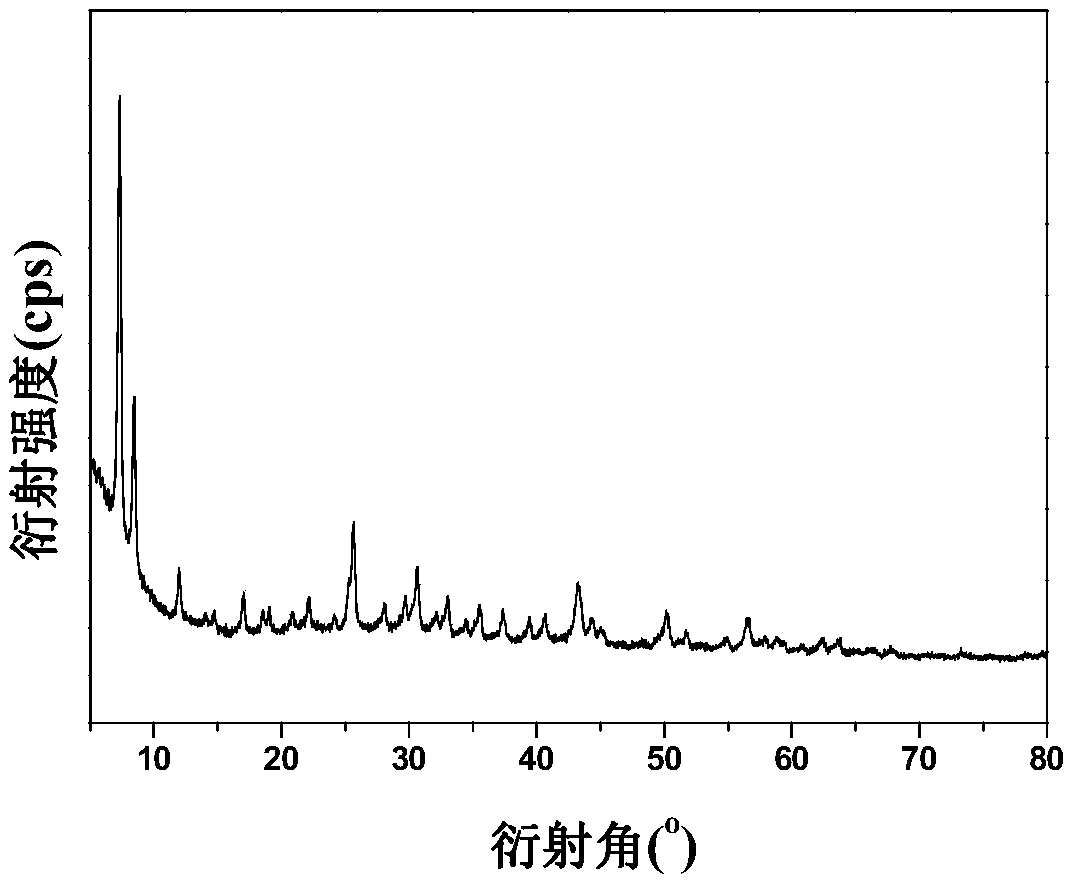

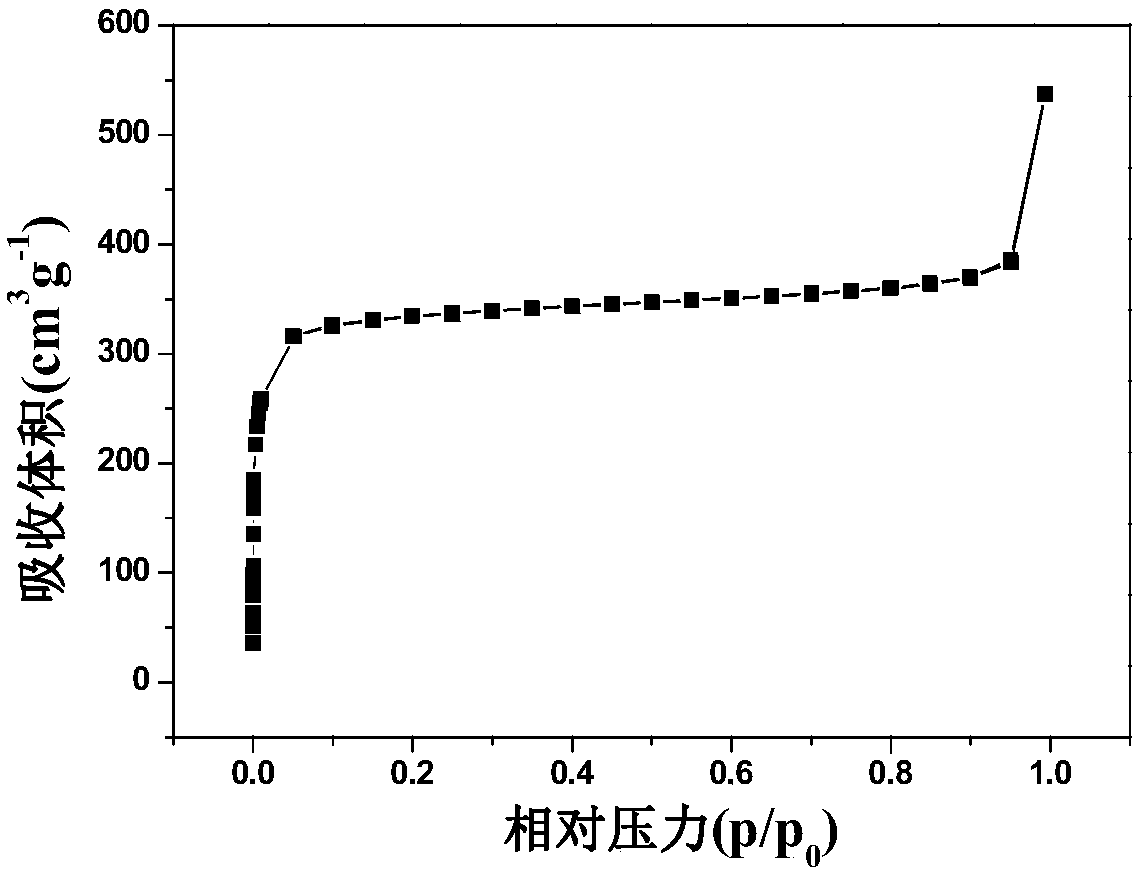

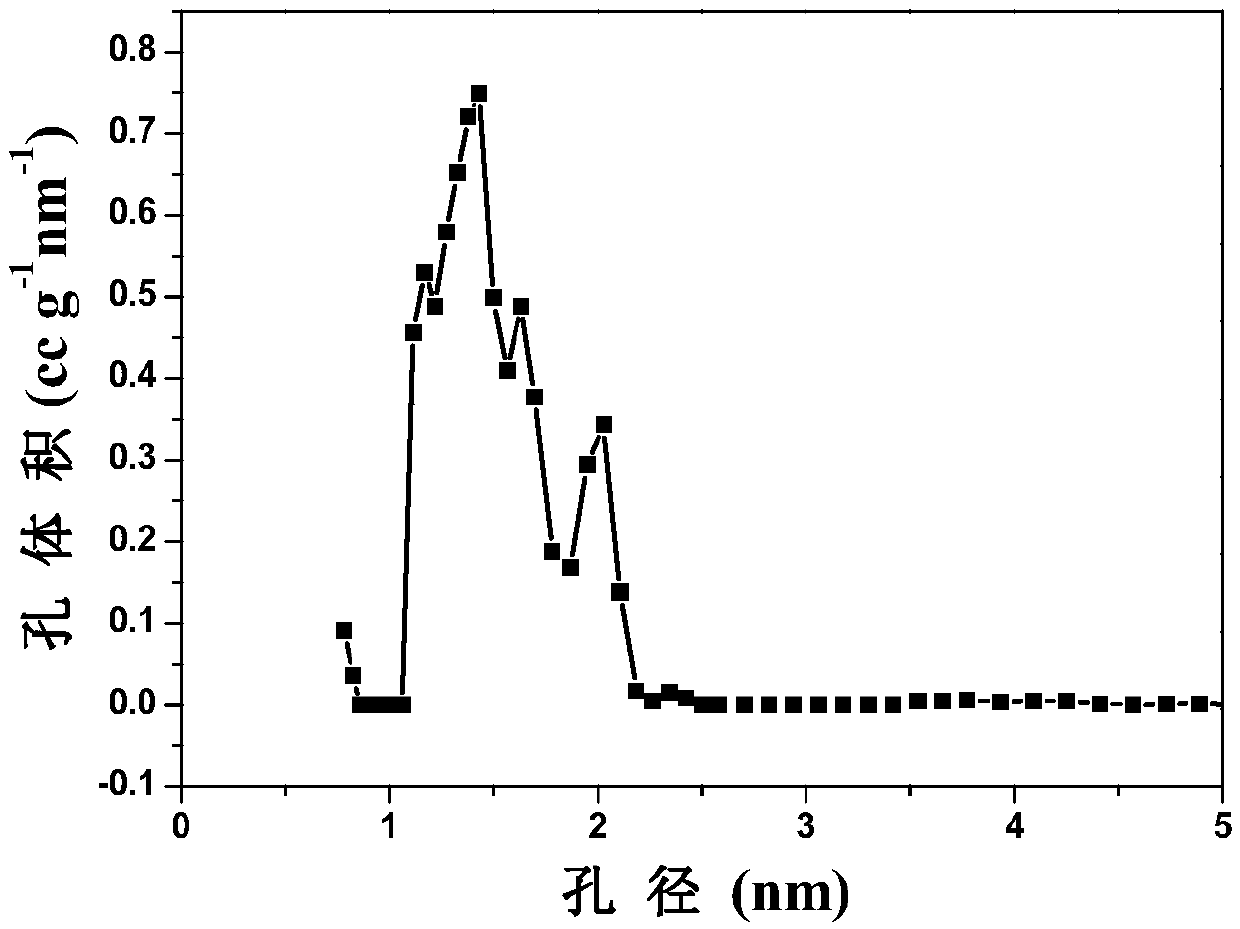

[0037] Weigh 0.053g of zirconium chloride and 0.034g of terephthalic acid and dissolve them completely in 5mL of N,N-dimethylformamide solvent; React at 120° C. for 24 hours; wash, filter, and dry the obtained product to obtain a solid Zr-based metal-organic framework adsorbent UiO-66. Its XRD, N 2 Adsorption-desorption, pore size distribution and TEM results are as follows figure 1 , as shown in 2, 3, and 4.

[0038] The dynamic adsorption capacity evaluation of the adsorbent was carried out in a fixed-bed continuous flow differential reactor. The reactor was a glass U-shaped tube with an inner diameter of 4 mm. The loading amount of the adsorbent was 200 mg. The toluene in the final gas was analyzed online by a GC-2060 gas chromatograph equipped with a hydrogen flame detector, and the adsorption amount was calculated by a breakthrough curve. The results of the breakthrough curve are shown in Figure 5 . Tests show that the UiO-66 adsorbent prepared by this method has a r...

Embodiment 2

[0040]Weigh 0.053g zirconium chloride, 0.034g terephthalic acid, weigh a certain amount of CTAB according to the CTAB / Zr molar ratio of 0.1, and dissolve them completely in 5mL N,N-dimethylformamide solvent; transfer the solution React in a stainless steel reaction kettle with a polytetrafluoroethylene liner at 120°C for 24 hours; wash, filter, and dry the obtained product, perform ethanol Soxhlet extraction, and dry to obtain a modified adsorbent. The evaluation method of the adsorbent is the same as in Example 1. Tests show that the UiO-66 adsorbent prepared by this method has a relatively high toluene adsorption capacity at room temperature (25°C).

Embodiment 3

[0042] Weigh 0.053g zirconium chloride, 0.034g terephthalic acid, weigh a certain amount of CTAB according to the CTAB / Zr molar ratio of 0.3, and dissolve them completely in 5mL N,N-dimethylformamide solvent; transfer the solution React in a stainless steel reaction kettle with a polytetrafluoroethylene liner at 120°C for 24 hours; wash, filter, and dry the obtained product, perform ethanol Soxhlet extraction, and dry to obtain a modified adsorbent. The evaluation method of the adsorbent is the same as in Example 1. Tests show that the UiO-66 adsorbent prepared by this method has a relatively high toluene adsorption capacity at room temperature (25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com