A solvothermal green and high-efficiency regeneration method of scr denitration catalyst for sintering flue gas failure

A denitrification catalyst and catalyst technology, applied in the field of denitrification catalysis, can solve the problem of high processing cost, achieve the effects of avoiding secondary pollution, high regeneration activity, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

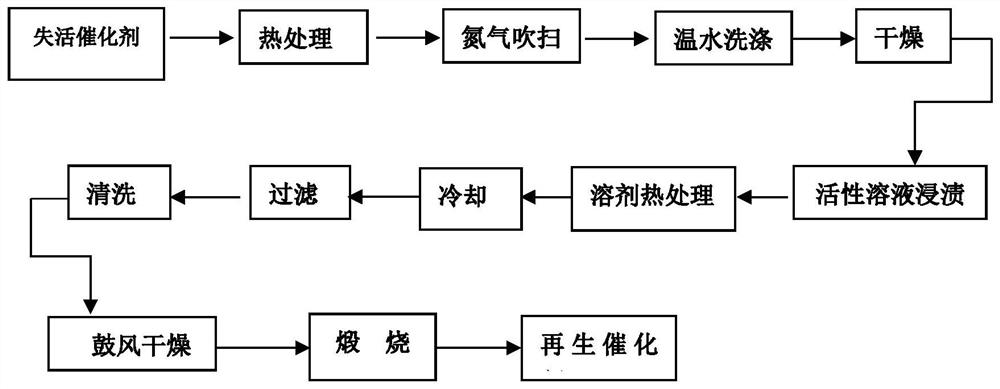

Method used

Image

Examples

Embodiment 1

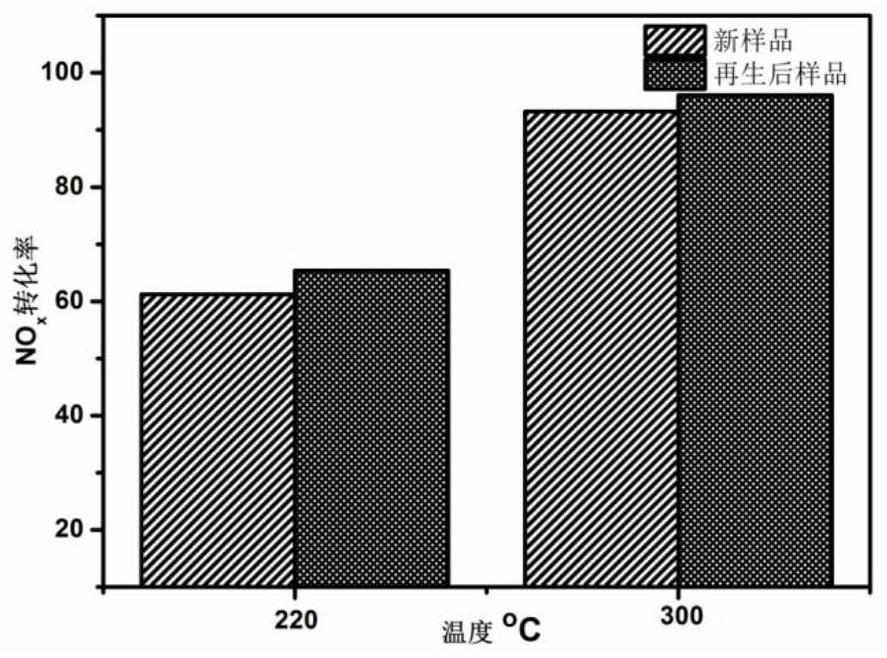

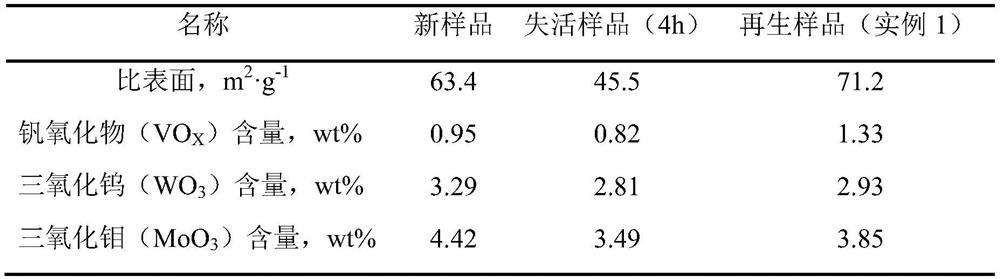

[0031] The deactivated SCR denitrification catalyst was first heat-treated at 400°C and purged with high-pressure nitrogen for 1 hour to remove dust and sulfate on the surface of the catalyst; then the treated catalyst was washed with warm water at 70°C and dried at 110°C for 12 hours; The catalyst is immersed in the activity recovery solution for activity recovery. The activity recovery solution is a mixture of 0.0146g vanadyl acetylacetonate, 0.032g ammonium metatungstate, 0.054g ammonium molybdate, and 50ml water, ethanol and DMF. As a solvent (the volume ratio of water, ethanol and DMF is 1:1:1), the inactivated sample was stirred with the mixed solution for 30min, and immersed for 2h; Water heating at 180°C for 6 hours in the reaction kettle; the heat-treated catalyst solution was naturally cooled to room temperature, filtered, washed with water, and air-dried at 120°C for 12 hours; finally calcined at 500°C for 2 hours under the protection of nitrogen to obtain the regene...

Embodiment 2

[0038] The deactivated SCR denitrification catalyst was first heat-treated at 400°C and purged with high-pressure nitrogen for 1 hour to remove dust and sulfate on the surface of the catalyst; then the treated catalyst was washed with warm water at 70°C and dried at 120°C for 12 hours; The catalyst is immersed in the activity recovery solution for activity recovery. The activity recovery solution is a mixture of 0.0146g vanadyl acetylacetonate, 0.032g ammonium metatungstate, 0.054g ammonium molybdate, and 50ml water, ethanol and DMF. As a solvent (the volume ratio of water, ethanol and DMF is 1:1:1), the inactivated sample was stirred with the mixed solution for 30min, and immersed for 2h; Heat water at 160°C for 6 hours in the reaction kettle; the heat-treated catalyst solution was naturally cooled to room temperature, filtered, washed with water, and air-dried at 120°C for 12 hours; finally calcined at 500°C for 2 hours under the protection of nitrogen to obtain the regenerated...

Embodiment 3

[0040] The deactivated SCR denitrification catalyst was first heat-treated at 400°C and purged with high-pressure nitrogen for 1 hour to remove dust and sulfate on the surface of the catalyst; then the treated catalyst was washed with warm water at 70°C and dried at 110°C for 12 hours; The catalyst is immersed in the activity recovery solution for activity recovery. The activity recovery solution is a mixture of 0.0146g vanadyl acetylacetonate, 0.032g ammonium metatungstate, 0.054g ammonium molybdate, and 50ml water, ethanol and DMF. As a solvent (the volume ratio of water, ethanol and DMF is 1:1:1), the inactivated sample was stirred with the mixed solution for 30min, and immersed for 2h; Heat water at 200°C for 2 hours in the reaction kettle; the heat-treated catalyst solution was naturally cooled to room temperature, filtered, washed with water, and dried at 150°C for 8 hours; finally calcined at 500°C for 1 hour under the protection of nitrogen to obtain the regenerated cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com