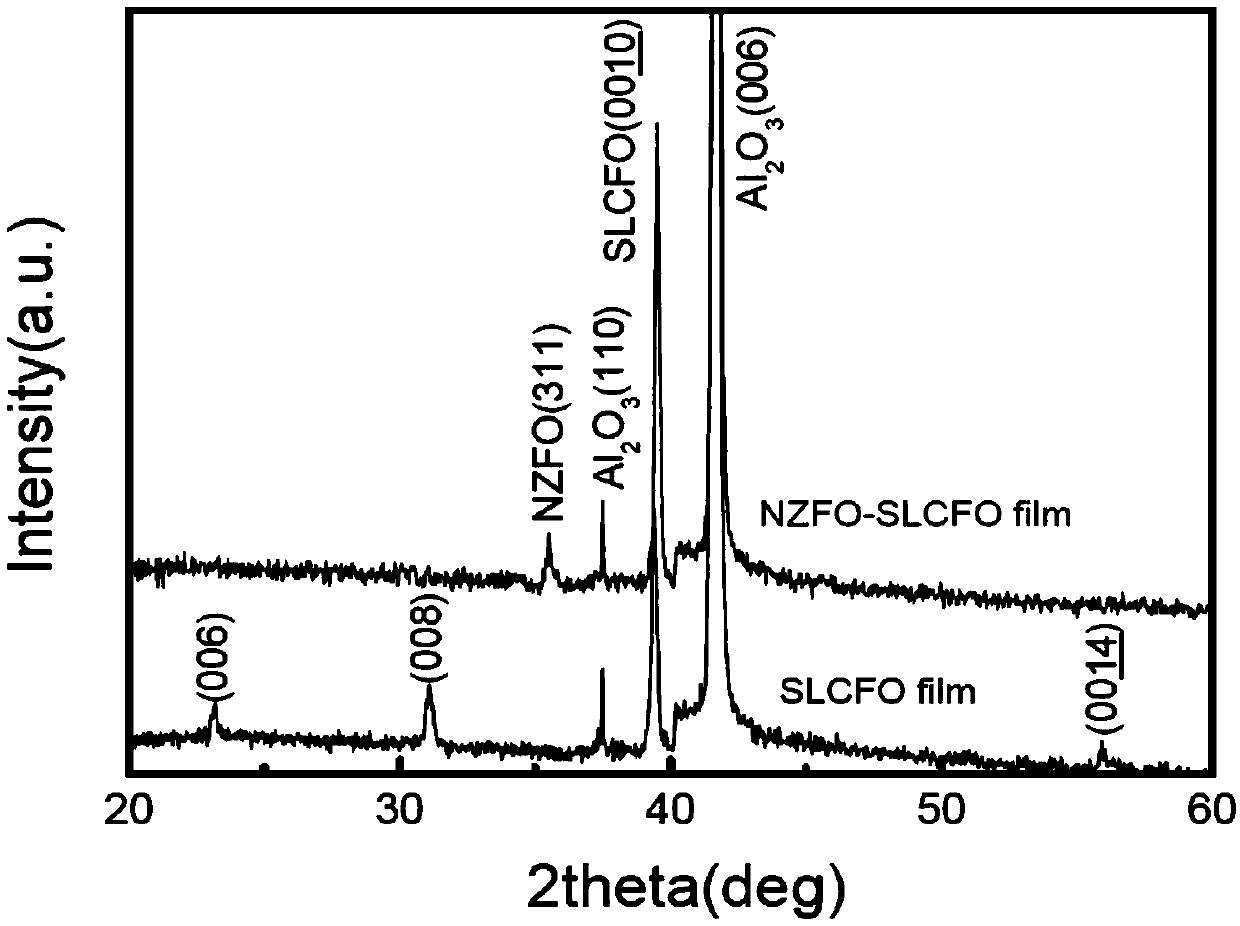

Preparation method of all-oxide soft-hard magnetic composite film (NZFO/SLCFO)3/Al2O3

A composite thin film and oxide technology, which is applied in the application of magnetic film to substrate, chemical vapor deposition application, heat treatment application, etc., can solve the problems of chemical preparation of ferrite multilayer composite thin film materials that have not been seen, and achieve Low cost, improved stability, and the effect of avoiding coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An all-oxide soft-hard magnetic composite film (NZFO / SLCFO) 3 / Al 2 o 3 A preparation method comprising the steps of:

[0027] S1. Weigh nickel nitrate, zinc nitrate, and iron citrate respectively according to the molar ratio of nickel, zinc, and iron at 0.65:0.35:2.0, and dissolve nickel nitrate, zinc nitrate, and iron citrate in monomethyl diethyl ether aqueous solution respectively. , mix evenly, add polyethylene glycol with a molecular weight of 18000, heat to 30°C and stir for reaction, then let stand for 1d to obtain Ni 0.65 Zn 0.35 Fe 2 o 4 Precursor colloid;

[0028] S2. Weigh strontium nitrate, lanthanum nitrate, iron citrate, and cobalt nitrate respectively according to the molar ratio of strontium, lanthanum, iron, and cobalt as 0.75:0.25:11.75:0.25, respectively After dissolving in monomethyl diethyl ether aqueous solution, mix evenly, add polyethylene glycol with a molecular weight of 22000, heat to 70°C and stir for reaction, then let stand for 90 d...

Embodiment 2

[0032] An all-oxide soft-hard magnetic composite film (NZFO / SLCFO) 3 / Al 2 o 3 A preparation method comprising the steps of:

[0033] S1. Weigh nickel nitrate, zinc nitrate, and iron citrate respectively according to the molar ratio of nickel, zinc, and iron of 0.7:0.3:2.0, and dissolve the nickel nitrate, zinc nitrate, and iron citrate in monomethyl diethyl ether aqueous solution respectively. , mix evenly, add polyethylene glycol with a molecular weight of 22000, heat to 70°C and stir for reaction, then let stand for 90d to obtain Ni 0.7Zn 0.3 Fe 2 o 4 Precursor colloid;

[0034] S2. Weigh strontium nitrate, lanthanum nitrate, iron citrate, and cobalt nitrate respectively according to the molar ratio of strontium, lanthanum, iron, and cobalt as 0.8:0.2:11.8:0.2, respectively After dissolving in monomethyl diethyl ether aqueous solution, mix evenly, add polyethylene glycol with a molecular weight of 18000, heat to 30°C and stir for reaction, then let stand for 1d to ob...

Embodiment 3

[0038] An all-oxide soft-hard magnetic composite film (NZFO / SLCFO) 3 / Al 2 o 3 A preparation method comprising the steps of:

[0039] S1. Weigh nickel nitrate, zinc nitrate, and iron citrate respectively according to the molar ratio of nickel, zinc, and iron at 0.6:0.4:2.0, and dissolve nickel nitrate, zinc nitrate, and iron citrate in monomethyl diethyl ether aqueous solution respectively. , mix evenly, add polyethylene glycol with a molecular weight of 20000, heat to 50°C and stir for reaction, then let stand for 40d to obtain Ni 0.6 Zn 0.4 Fe 2 o 4 Precursor colloid;

[0040] S2. Weigh strontium nitrate, lanthanum nitrate, iron citrate, and cobalt nitrate respectively according to the molar ratio of strontium, lanthanum, iron, and cobalt as 0.8:0.2:11.8:0.2, respectively After dissolving in monomethyl diethyl ether aqueous solution, mix evenly, add polyethylene glycol with a molecular weight of 20,000, heat to 50°C and stir for reaction, then let stand for 50 days to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com