Negative electrode for lithium battery and preparation method thereof and lithium battery

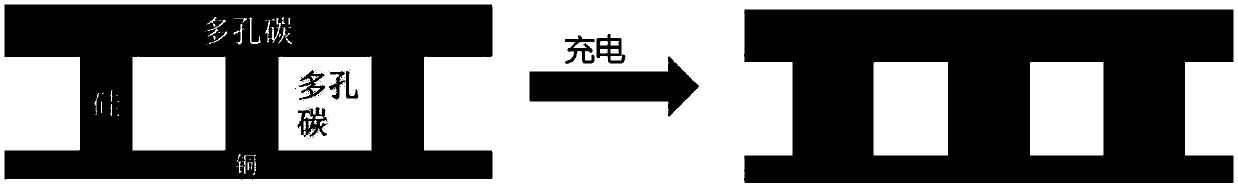

A lithium battery and negative electrode technology, applied in the field of lithium battery electrodes, can solve problems such as poor cycle stability, limit the energy density of lithium ion batteries, affect battery capacity, etc., and achieve the goal of ensuring stability, maintaining integrity and stability, and maintaining performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

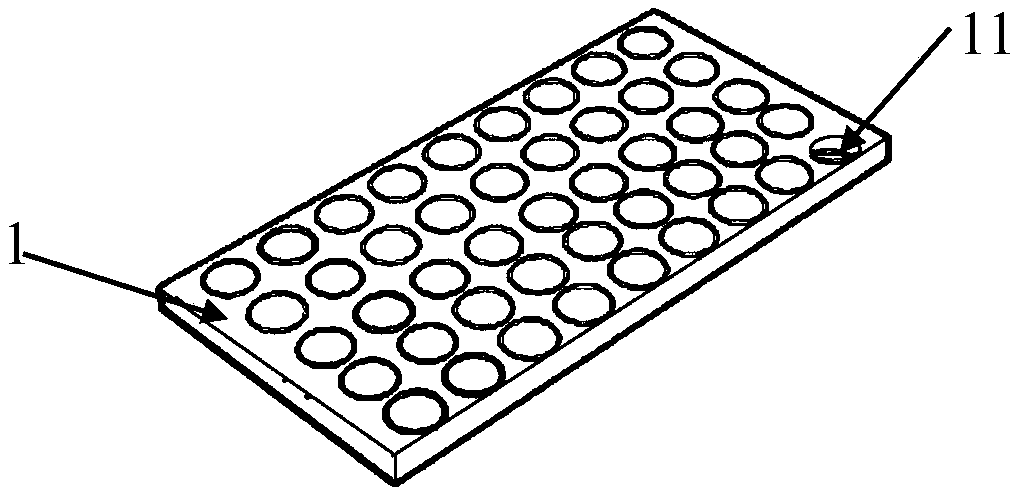

[0068] A circular hole mask plate with a thickness of 40 μm, a through hole diameter of 10 μm, and a distance between circle centers of 30 μm was tightly attached to the copper current collector.

[0069] Weigh silicon powder (average particle size 100nm), PVDF and acetylene black and disperse them in N-methylpyrrolidone to make silicon slurry. The weight ratio of each component in the material is 90:5:5.

[0070] Apply the silicon slurry on the copper current collector with the mask plate; then gently remove the mask plate, leaving a cylindrical silicon molding unit on the copper current collector; then place it in a vacuum oven, Take it out after baking at 120°C for 2 hours to obtain a copper current collector / cylindrical silicon electrode.

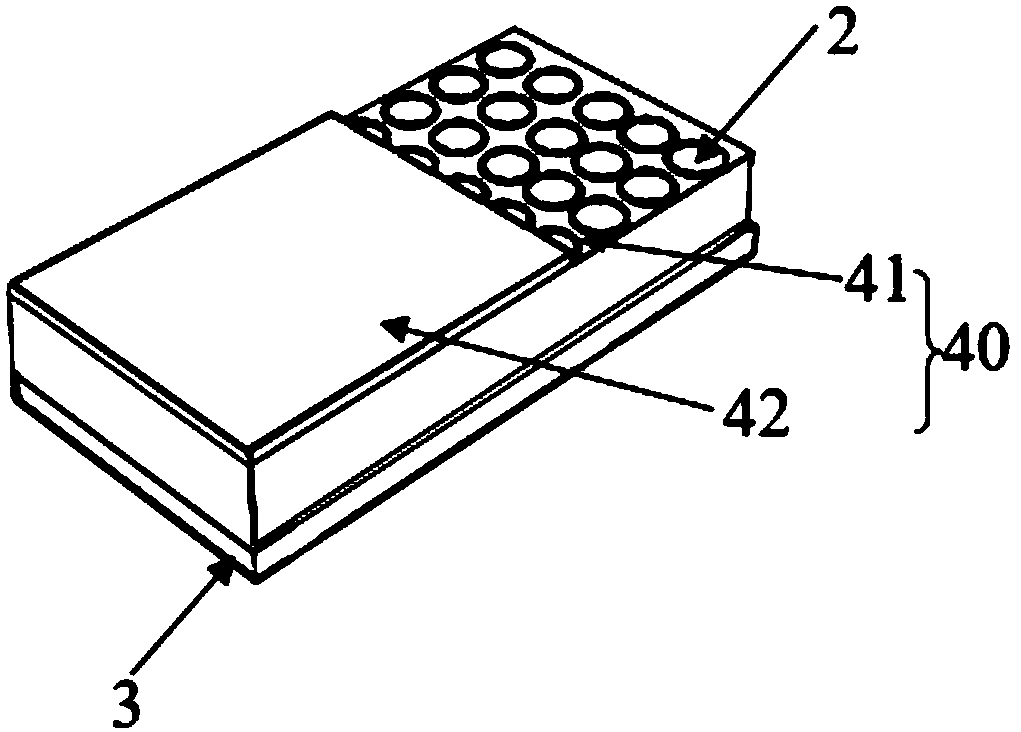

[0071] Weigh graphene, PTFE and acetylene black and disperse them in N-methylpyrrolidone to make graphene slurry. The weight ratio of each component in the material is 80:10:10. Then apply graphene slurry on the exposed current collect...

Embodiment 2

[0074] A circular hole mask with a thickness of 100 μm, a through hole diameter of 50 μm, and a distance between circle centers of 70 μm was tightly attached to the copper current collector.

[0075] Weigh silicon powder (average particle size is 150nm), natural graphite, PVDF and acetylene black and disperse in N-methylpyrrolidone to make silicon-natural graphite slurry. The weight ratio of each component in the material is 80:10: 5:5.

[0076] The silicon-natural graphite slurry is coated on the copper current collector with a mask plate; then the mask plate is gently removed, leaving a cylindrical silicon-natural graphite on the copper current collector; then it is placed on the In a vacuum oven, bake at 120°C for 2 hours and take it out to obtain a copper current collector / (cylindrical silicon-natural graphite) electrode.

[0077] Weigh graphene, PTFE and acetylene black and disperse them in N-methylpyrrolidone to make graphene slurry. The weight ratio of each component i...

Embodiment 3

[0080] First, a square-hole mask plate with a thickness of 100 μm, a through-hole side length of 100 μm, and a center-to-hole distance of 160 μm was tightly attached to the nickel current collector. Weigh silicon powder (average particle size is 50nm), hard carbon, polyacrylonitrile and acetylene black and disperse in N-methylpyrrolidone to make silicon-hard carbon slurry. The weight ratio of each component in the material is 50: 40:5:5. Coat the silicon-hard carbon slurry on the nickel current collector with the mask plate; then gently remove the mask plate, leaving a square column-shaped silicon-hard carbon on the nickel current collector; then place it on the In a vacuum oven, bake at 120 degrees for 2 hours and take it out to obtain a nickel current collector / (square columnar silicon-hard carbon) electrode.

[0081] Weigh mesoporous carbon (average pore diameter about 5nm), PTFE and acetylene black and disperse them in N-methylpyrrolidone to make mesoporous carbon slurry....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com