Preparation method for high-temperature-resistant thermal-insulation aerogel felt

An aerogel felt, high temperature resistant technology, applied in the field of aerogel felt, can solve the problems of low solid content, low mechanical strength, poor machinability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

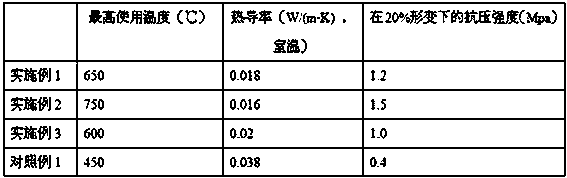

Examples

Embodiment 1

[0030] A kind of preparation method of high temperature resistant heat insulation airgel felt, the steps are as follows:

[0031] (1) Disperse SiC whiskers (200nm in diameter) and cellulose in a graphene aqueous suspension (solid content: 3g / L) to obtain suspension A;

[0032] (2) Add hollow glass microspheres to suspension A under stirring to obtain suspension B;

[0033] (3) Mix ethyl orthosilicate, absolute ethanol and water evenly, then add 2mol / L NH 4 Stir F solution and 0.2moL / L ammonia water evenly to obtain silica sol C;

[0034] (4) Add the suspension B into the silica sol C under stirring, and use it to soak the glass fiber mat after stirring evenly (in actual operation, the glass fiber mat can be placed in a container in advance, and then injected into the second The mixture of silica sol and slurry B), impregnate the glass fiber mat on a vibrating platform (vibration power is 1.6 KW, vibration frequency is 400 HZ, vibration time is 1 h), after dipping for 48 h, t...

Embodiment 2

[0043] A kind of preparation method of high temperature resistant heat insulation airgel felt, the steps are as follows:

[0044] (1) Disperse SiC whiskers (diameter: 150nm) and cellulose in graphene aqueous suspension (solid content: 2g / L) to obtain suspension A;

[0045] (2) Add hollow glass microspheres to suspension A under stirring to obtain suspension B;

[0046](3) Mix ethyl orthosilicate, absolute ethanol and water evenly, then add 2mol / L NH 4 Stir F solution and 0.2moL / L ammonia water evenly to obtain silica sol C;

[0047] (4) Add the suspension B into the silica sol C under stirring, and use it to soak the glass fiber mat after stirring evenly (in actual operation, the glass fiber mat can be placed in a container in advance, and then injected into the second Mixture of silica sol and slurry B), impregnate the glass fiber mat on a vibration platform (vibration power 1.3KW, vibration frequency 300 HZ, vibration time 1.5h), after 36h of impregnation, take out the gla...

Embodiment 3

[0056] A kind of preparation method of high temperature resistant heat insulation airgel felt, the steps are as follows:

[0057] (1) Disperse SiC whiskers (100nm in diameter) and cellulose in graphene aqueous suspension (solid content: 5g / L) to obtain Suspension A;

[0058] (2) Add hollow glass microspheres to suspension A under stirring to obtain suspension B;

[0059] (3) Mix ethyl orthosilicate, absolute ethanol and water evenly, then add 2mol / L NH 4 Stir F solution and 0.2moL / L ammonia water evenly to obtain silica sol C;

[0060] (4) Add the suspension B into the silica sol C under stirring, and use it to soak the glass fiber mat after stirring evenly (in actual operation, the glass fiber mat can be placed in a container in advance, and then injected into the second Mixture of silica sol and slurry B), impregnate the glass fiber mat on a vibrating platform (vibration power 1.8 KW, vibration frequency 500HZ, vibration time 2h), after 24h of impregnation, take out the gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com