Composite depolymerizing agent for delta-valerolactone polymer, and using method of composite depolymerizing agent

A depolymerization agent, valerolactone technology, applied in the direction of organic chemistry, etc., can solve the problem of no good polymerization inhibition effect, achieve excellent depolymerization effect, simple operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of composite depolymerization agent of δ-valerolactone polymer, described composite depolymerization agent comprises depolymerization agent, stabilizer and water removal agent, and described depolymerization agent is made of stannous octoate and / or 1,3-di It is composed of substituting imidazole carbene; the stabilizer is selected from alkyl phosphorous acid; the dewatering agent is selected from calcium carbonate. The composite depolymerizing agent is prepared by mixing the depolymerizing agent: stabilizer: dewatering agent at a ratio of 100:5:15 (by mass).

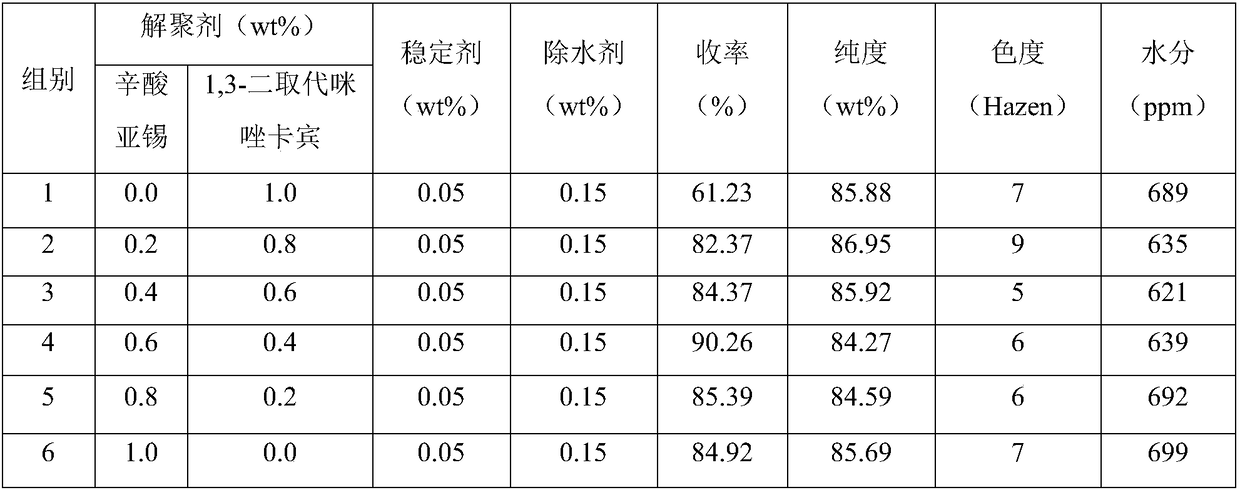

[0019] The depolymerization experiment was divided into 6 groups according to the content of stannous octoate and 1,3-disubstituted imidazocarbene in the composite depolymerization agent. Group 1: no stannous octoate, only 1,3-disubstituted imidazocarbene; Group: The mass ratio of stannous octoate and 1,3-disubstituted imidazocarbene is 1:4; Group 3: The mass ratio of stannous octoate and 1,3-disubstituted ...

Embodiment 2

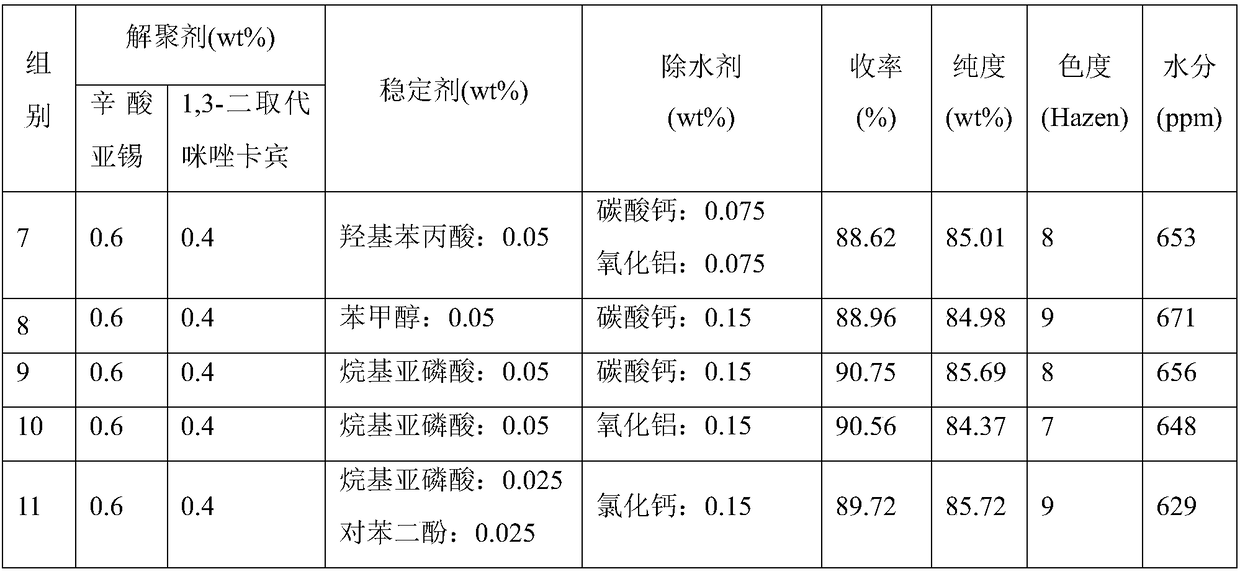

[0025] Mix and prepare the depolymerizing agent with the mass ratio of depolymerizing agent: stabilizer: dewatering agent being 100:5:15. Wherein the depolymerization agent is stannous octoate and 1,3-disubstituted imidazocarbene, the mass ratio of stannous octoate and 1,3-disubstituted imidazolcarbene is 3:2; the stabilizer is composed of alkyl phosphorous acid, aromatic phosphorous acid , hydroxyphenylpropionic acid, benzyl alcohol or hydroquinone or one or more of them; the dewatering agent is composed of one or two of clay, alumina, silica gel, zeolite, calcium chloride, calcium carbonate or potassium bicarbonate more than one composition.

[0026] The depolymerization experiment was divided into 5 groups according to the difference between the stabilizer and the dehydrating agent in the composite depolymerizing agent. Group 7: the stabilizer was hydroxyphenylpropionic acid, the dehydrating agent was calcium carbonate and aluminum oxide, and The mass ratio is 1:1; Group 8...

Embodiment 4

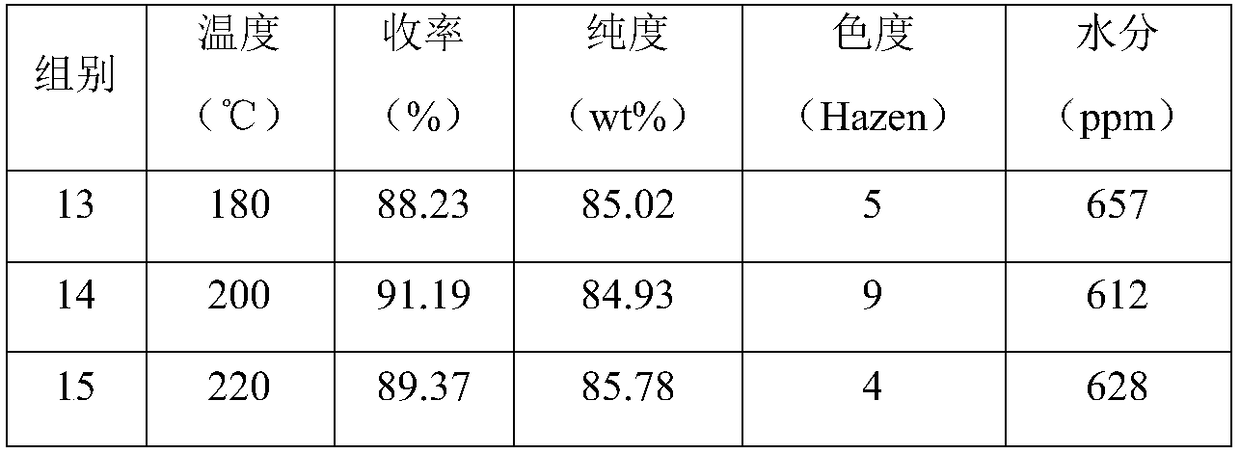

[0037] A kind of composite depolymerization agent of δ-valerolactone polymer, described composite depolymerization agent comprises depolymerization agent, stabilizer and water removal agent, and described depolymerization agent is made of stannous octoate and 1,3-disubstituted imidazole Composed of carbene; the stabilizer is made of alkyl phosphorous acid; the dewatering agent is made of calcium carbonate. The composite depolymerizer is prepared by mixing stannous octoate: 1,3-disubstituted imidazocarbene: alkyl phosphorous acid: calcium carbonate at a ratio of 60:40:5:15 (by mass).

[0038]The depolymerization experiment was divided into three groups according to the different depolymerization reaction temperatures: Group 13, the reaction temperature was 180°C; Group 14, the reaction temperature was 200°C; Group 15, the reaction temperature was 220°C.

[0039] The depolymerization steps of δ-valerolactone polymers are as follows: 300g of δ-valerolactone polymers melted under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com