Gel cleaning agent used for kitchen

A gel-like, detergent-based technology, applied in detergent materials, detergent compositions, detergent compounding agents, etc., can solve problems such as short contact time, high cost, and high pH value of detergents, and achieve raw material safety and environmental protection, The effect of reducing application cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

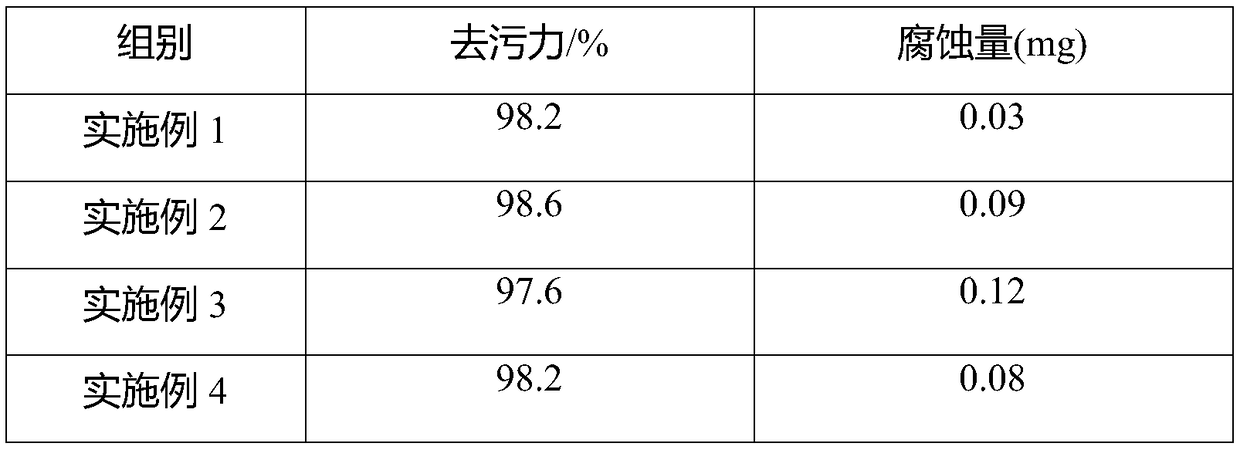

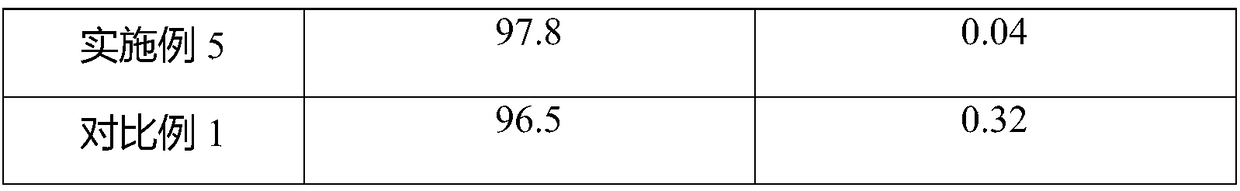

Examples

Embodiment 1

[0021] Kitchen gel-like cleaner: by weight percentage, isomerized fatty acid ester ethyl sulfonate 5%; sodium glutamate diacetate 4.5%; diethylene glycol butyl ether 5%; potassium hydroxide 0.75%; Mu 1.5%; 83.25% is water.

[0022] The preparation method is: add 83.25% of water, 1.5% of carbomer, stir and dissolve evenly; add 4.5% of sodium glutamate diacetate, 5% of isomeric fatty acid ethyl sulfonate, 5% of diethylene glycol butyl ether, and stir Dissolve evenly; adjust the pH to 6.8-7.2 with 0.75% potassium hydroxide, and the viscosity is 2000-6000mPa·S.

[0023] The pH of the formula system in this example is 7.0, and it is in the form of a transparent gel when it is left standing. When it is sheared and thinned by any conventional spray head, it is sprayed in a mist form, and it quickly recovers in a gel form after contacting the oily surface. Adsorbed on the oily surface, when the gel-like detergent reacts with the oily surface, it can be rinsed off with water directly....

Embodiment 2

[0025] Kitchen gel cleaner: by weight percentage, isomerized fatty acid ester ethyl sulfonate 1.5%; octylphenol polyoxyethylene ether 3%; disodium edetate 4%; diethylene glycol butyl ether 4%; potassium hydroxide 0.49%; carbomer 1%; xanthan gum 0.5%; water 85.51%.

[0026] The preparation method is: add 85.51% of water, 1% of carbomer, 0.5% of xanthan gum, stir and dissolve evenly; 4% alcohol butyl ether, stir and dissolve evenly; use 0.49% potassium hydroxide to adjust the pH to 7.0-7.5, and the viscosity is 5000-10000mPa·S.

[0027] The pH of the formulation system in this example is 7.2, and it is in the form of a transparent gel when it is left standing. When it is sheared and thinned by any conventional spray head, it will be sprayed in a mist form, and it will return to a gel form after contacting the oily surface, and it will be firmly adsorbed. On the oily surface, the droplets are heavier than those in Example 1 during the atomization process, and can be used in plac...

Embodiment 3

[0029] Kitchen gel cleaner: by weight, octylphenol ethoxylate 3%; disodium edetate 4%; diethylene glycol butyl ether 4%; potassium hydroxide 0.55%; Mu 1%; xanthan gum 0.5%; water 86.95%.

[0030] The preparation method is: add 86.95% of water, 1% of carbomer, 0.5% of xanthan gum, stir and dissolve evenly; add 4% of disodium edetate, 3% of octylphenol polyoxyethylene ether, diethylene glycol 4% butyl ether, stir and dissolve evenly; use 0.55% potassium hydroxide to adjust the pH to 7.0-7.5, and the viscosity is 2000-5000mPa·S.

[0031] The pH of the formula system in this example is 8.5, and it is in the form of a transparent gel when it is left standing. It is sheared and thinned by the spray head and sprayed out in the form of a mist. After contacting the oily surface, it quickly recovers to be in the form of a gel, and is firmly adsorbed on the oily surface. , when the gel-like cleaner reacts with the oily surface, it can be rinsed off with water directly. Compared with Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com