Long-acting moisturizing gel with deep penetration and preparation method

A technology of moisturizing gel and deep penetration, applied in the field of skin care products, can solve the problems of short moisturizing duration, poor slow release, difficult deep penetration, etc., and achieve the effects of improving moisturizing effect and durability, preventing loss and promoting skin expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

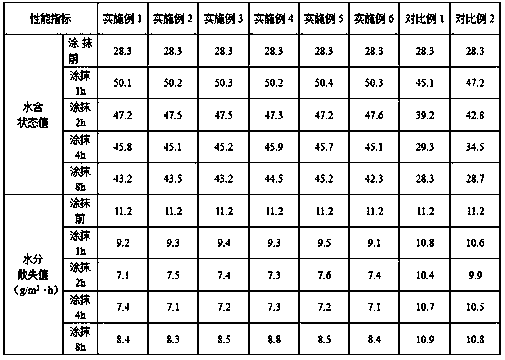

Examples

Embodiment 1

[0029] (1) Mix low-molecular-weight hyaluronic acid, silica airgel, and chitosan to make a colloid; in the colloid, 63 parts by weight of low-molecular-weight hyaluronic acid, 24 parts by weight of silica airgel, 13 parts by weight of chitosan;

[0030] (2) Add polylactic acid hollow fibers to the colloidal liquid prepared in step (1), disperse uniformly by ultrasonic waves, and then perform vacuum treatment to fill the colloidal liquid in the hollow pores of polylactic acid hollow fibers to obtain composite fibers; polylactic acid The average outer diameter of the hollow fiber is 0.5mm, the average wall thickness is 0.1mm, and the average length is 2mm; the ultrasonic frequency of ultrasonic dispersion is 48kHz, and the power density is 0.7W / cm 2 , the time is 30min; the vacuum degree of vacuum treatment is 30Pa, and the treatment time is 32min;

[0031] (3) Mix the composite fiber prepared in step (2) with azone, menthol, organic amine, stearic acid, monoglyceride, carbo re...

Embodiment 2

[0033] (1) Mix low-molecular-weight hyaluronic acid, silica airgel, and chitosan to make a colloid; in the colloid, 70 parts by weight of low-molecular-weight hyaluronic acid, 20 parts by weight of silica airgel, 10 parts by weight of chitosan;

[0034] (2) Add polylactic acid hollow fibers to the colloidal liquid prepared in step (1), disperse uniformly by ultrasonic waves, and then perform vacuum treatment to fill the colloidal liquid in the hollow pores of polylactic acid hollow fibers to obtain composite fibers; polylactic acid The average outer diameter of the hollow fiber is 0.4mm, the average wall thickness is 0.1mm, and the average length is 1mm; the ultrasonic frequency of ultrasonic dispersion is 40kHz, and the power density is 0.5W / cm 2 , the time is 50min; the vacuum degree of vacuum treatment is 10Pa, and the treatment time is 40min;

[0035](3) Mix the composite fiber prepared in step (2) with azone, menthol, organic amine, stearic acid, monoglyceride, carbo res...

Embodiment 3

[0037] (1) Mix low-molecular-weight hyaluronic acid, silica airgel, and chitosan to make a colloid; in the colloid, 55 parts by weight of low-molecular-weight hyaluronic acid, 30 parts by weight of silica airgel, 15 parts by weight of chitosan;

[0038] (2) Add polylactic acid hollow fibers to the colloidal liquid prepared in step (1), disperse uniformly by ultrasonic waves, and then perform vacuum treatment to fill the colloidal liquid in the hollow pores of polylactic acid hollow fibers to obtain composite fibers; polylactic acid The average outer diameter of the hollow fiber is 0.8mm, the average wall thickness is 0.2mm, and the average length is 3mm; the ultrasonic frequency of ultrasonic dispersion is 60kHz, and the power density is 0.8W / cm 2 , the time is 20min; the vacuum degree of vacuum treatment is 50Pa, and the treatment time is 20min;

[0039] (3) Mix the composite fiber prepared in step (2) with azone, menthol, organic amine, stearic acid, monoglyceride, carbo re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com