Plasma seawater purifying equipment

A plasma and seawater technology, applied in seawater treatment, electrochemical water/sewage treatment, water/sewage treatment, etc., can solve the problems of equipment volume increase, large volume, high power consumption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

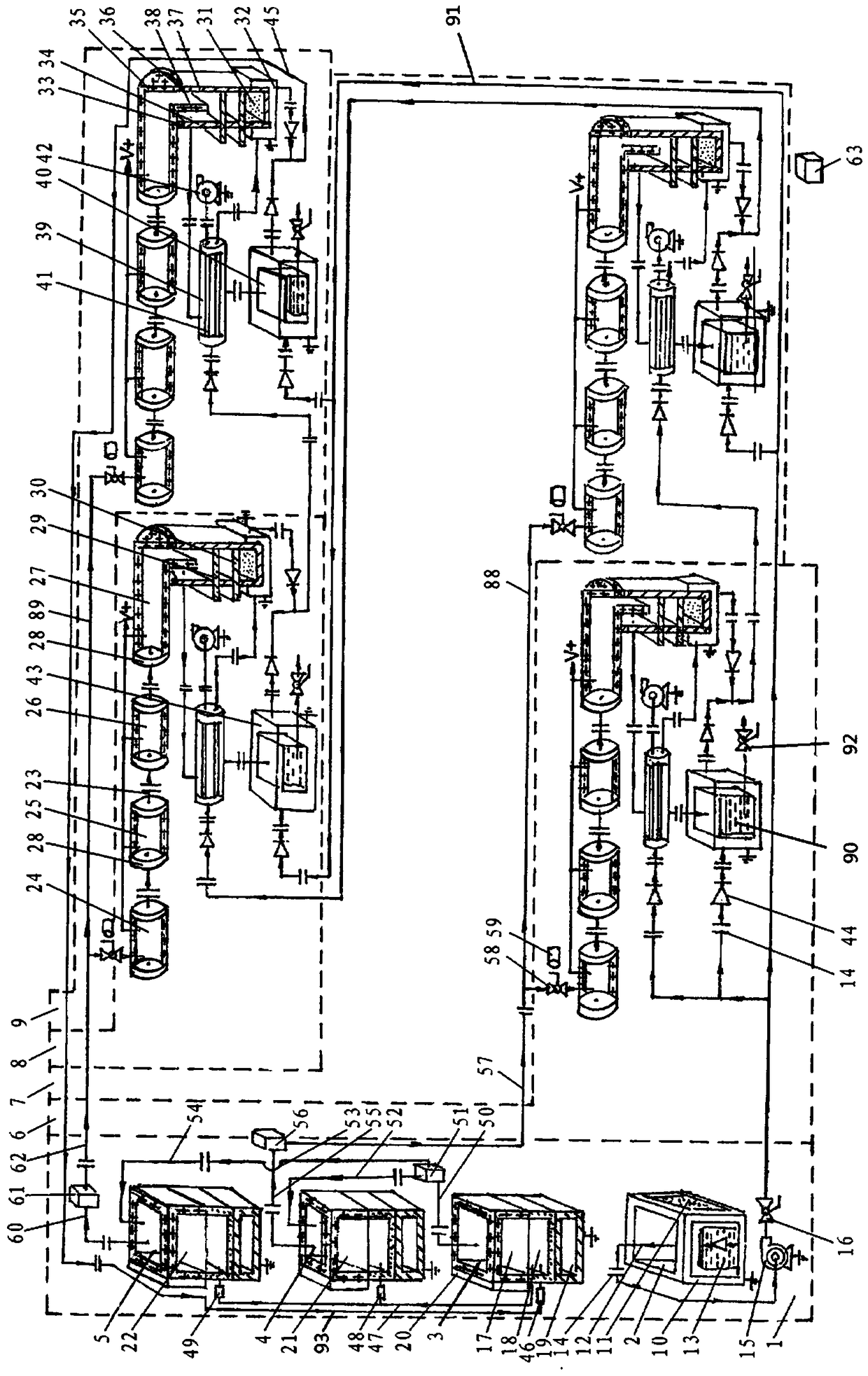

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, briefly explaining the flow process in which unpurified seawater is heated to nearly 100°C for four times, and describing in detail the process of plasma purification of seawater obtained by the country on the "Drinking Water Hygienic Standard" (GB5749- 2006) working principle of normal temperature standard drinking water.

[0049] see figure 1 , the plasma purification seawater equipment of the embodiment of the present invention, it comprises seawater plasma supply network 1, the first seawater purification unit 6, the second seawater purification unit 7, the third seawater purification unit 8, the fourth seawater purification unit 9; seawater plasma supply The network 1 includes a seawater supply network 2 , a seawater evaporation ionization network 3 , a first seawater boiling ionization network 4 , and a second seawater boiling ionization netw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com