Fat trifluoro ethyl ester compound and preparation method thereof

A fatty acid trifluoroethyl ester and trifluoroethyl ester technology, which is applied in the field of fatty trifluoroethyl ester compounds and their preparation, can solve the problems of low reaction efficiency, harsh reaction conditions, poor atom utilization, etc., and achieve increased yield , fewer side reactions, beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

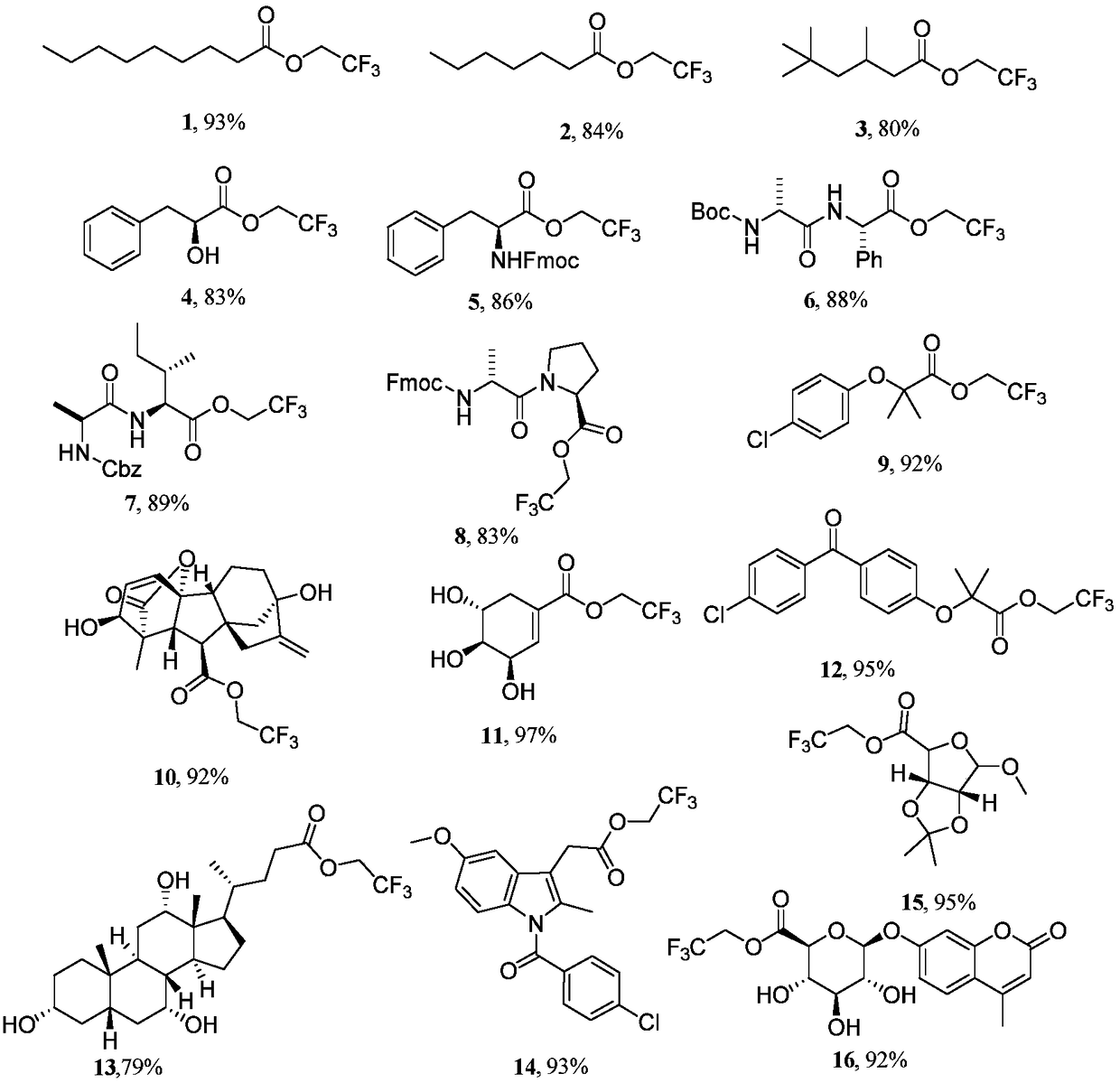

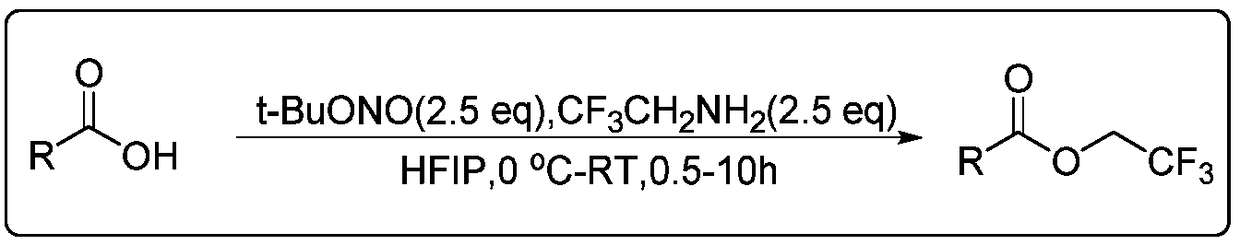

[0027] The following implementations 1-16 are prepared according to the following synthetic route, and compounds 1-16 can be prepared:

[0028]

[0029] The specific operation is: dissolve the fatty acid (0.5mmol, 1equiv) substrate in 1,1,1,3,3,3-hexafluoro-2-propanol, and add tert-butyl nitrite ( 150 μL, 1.25mmol, 2.5equiv) and 2,2,2-trifluoroethylamine (100 μL, 1.25mmol, 2.5equiv), stirred for 5min and raised to room temperature to continue the reaction for 0.5~10h, and depressurized the solution in the reaction system After spinning to dryness, the residue was purified by column chromatography to obtain fatty trifluoroethyl ester compounds.

Embodiment 1

[0031] Substrate: nonanoic acid

[0032] product:

[0033] Compound 1: colorless oil (107mg, 93% yield); IR(KBr)ν max / cm -1 :2959,2930,2859,1762, 1457,1412,1283,1170,1111,1067,979,842,807; 1 H NMR (400MHz, CDCl 3 )δ4.39(q, J=8.5 Hz, 2H, C H 2 CF 3 ), 2.34(t, J=7.5Hz, 2H, COC H 2 ),1.72–1.48(m,2H,COCH 2 C H 2 ), 1.22 (dd, J=12.8, 6.6Hz, 10H, C H 2 ),0.81(t,J=6.8Hz,3H,CH 2 C H 3 );13 C NMR (100MHz, CDCl 3 )δ 171.2(CO), 122.0(q, J=277.1Hz, C f 3 ),59.1(q,J=36.5Hz, C CF 3 ), 32.6 (CO C h 2 ), 30.8 (COCH 2 C h 2 ), 28.13, 28.08, 28.0, 23.7, 21.6, 13.0 (CH 2 C h 3 ); 19 F NMR (376MHz, CDCl 3 )δ -73.97(t, J=8.3Hz, C F 3 ); 19 F { 1 H}NMR (376MHz, CDCl 3 )δ-73.97(s,C F 3 ); HRMS(ESI): m / zcalcd for C 11 h 29 f 3 o 2 Na + [M+Na] + 263.1229, found 263.1242.

Embodiment 2

[0035] Substrate: Heptanoic acid

[0036] product:

[0037] Compound 2: colorless oil (89mg, 84% yield); IR(KBr)ν max / cm -1 :2961,2931,2858,1756,1419, 1285,1172,1107,909,807,735; 1 H NMR (400MHz, CDCl 3 )δ4.47(q, J=8.5Hz, 2H, C H 2 CF 3 ), 2.42(t,J=7.5Hz,2H,COC H 2 ), 1.66 (p, J=7.5Hz, 2H, C H 2 CH 3 ),1.48–1.22(m,6H),0.88(t,J=6.9Hz,3H,C H 3 ); 13 C NMR (100MHz, CDCl 3 )δ172.2(CO), 123.0(q, J=277.1Hz, C h 2 CF 3 ), 60.1(q, J=36.4Hz, C f 3 ), 33.7 (CO C h 2 ),31.4( C h 2 ),28.7( C h 2 ),24.7( C h 2 ),22.5( C h 2 ),14.0 ( C h 3 ); 19 F NMR (376MHz, CDCl 3 )δ-73.85(t, J=8.5Hz, C F 3 ); 19 F { 1 H}NMR (376MHz, CDCl 3 ) δ-73.85(s,C F 3 ); HRMS(ESI):m / z calcd for C 9 h 15 f 3 o 2 Na + [M+Na] + 235.0916,found235.0916.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com