Preparation method of choline bitartrate

A technology of choline bitartrate and choline, which is applied in the field of preparation technology of choline bitartrate, can solve the problems of high solubility of choline bitartrate, short service life of resin, and low product quality, and achieve high product quality and high product quality. Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

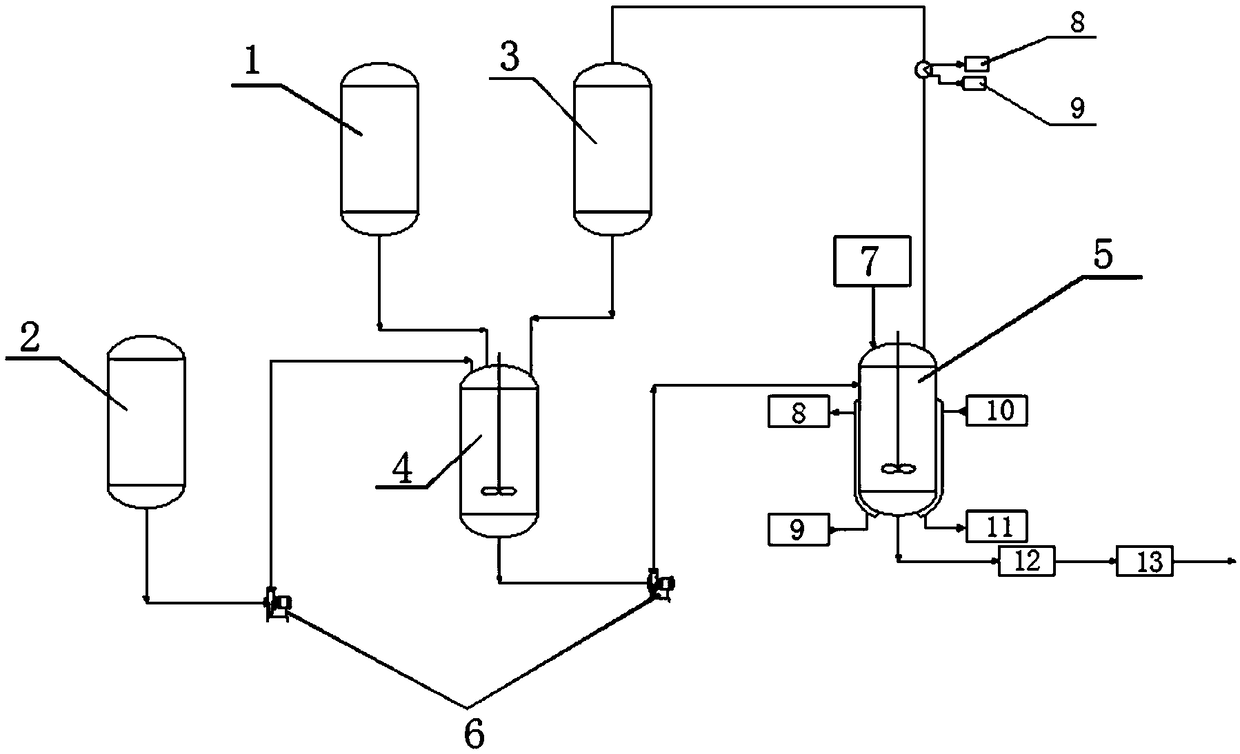

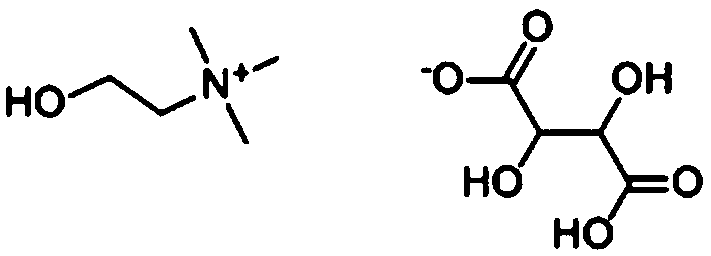

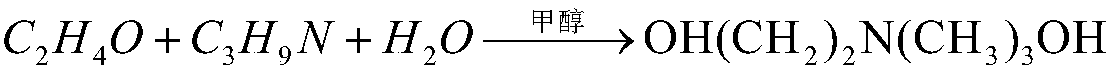

Method used

Image

Examples

Embodiment 1

[0039] 1500kg of aqueous ethylene oxide solution and 1000kg of methanol solution with a mass concentration of 40% are added into the choline reactor 4 replaced by nitrogen gas by gravity respectively, and 810kg of pure trimethylamine is added into the choline reactor 4 by pump 6, and the reaction pressure Be 0.2MPaG, react after 1 hour, send in the choline bitartrate reactor 5 with pump 6 choline solution 3310kg (choline content 1650kg). 2045kg of tartaric acid solids are added into the choline hydrogen tartrate reactor 5 with a sealed hopper again, the reaction pressure is 1kPaG, and the reaction temperature is 20°C. After reacting for 3 hours, feed low-pressure steam 10 into the jacket, and evaporate after 2 hours , then feed circulating water to cool down, and after being cooled to 45°C, the material is put into the centrifuge 12, and the solid material is sent to the drum dryer 13 for drying after the centrifugation, so as to obtain 3450kg of finished product choline bitart...

Embodiment 2

[0041] Respectively mass concentration is 50% ethylene oxide aqueous solution 1200kg, methanol solution 1000kg is added in the choline reactor 4 that has been replaced by nitrogen gas, pure trimethylamine 810kg joins in the choline reactor 4 by pump 6, reaction pressure Be 0.6MPaG, react after 1 hour, send in the choline bitartrate reactor 5 with pump 6 choline solution 3010kg (choline content 1650kg). Then 2045kg of tartaric acid solids are added to the choline bitartrate reactor 5 with a sealed hopper, the reaction pressure is 5kPaG, and the reaction temperature is 70°C. After reacting for 3 hours, feed the low-pressure steam 10 into the jacket, evaporate after 1.5 hours , then feed circulating water to cool down, and after being cooled to 45°C, the material is put into the centrifuge 12, and the solid material is sent to the drum dryer 13 for drying after the centrifugation, so as to obtain 3450kg of finished product choline bitartrate.

Embodiment 3

[0043] Respectively mass concentration is 60% ethylene oxide aqueous solution 1000kg, methanol solution 1000kg add in the choline reaction kettle 4 that has been replaced by nitrogen gas, pure trimethylamine 810kg joins in the choline reaction kettle 4 by pump, and reaction pressure is 0.4MPaG, after reacting 1 hour, choline solution 3010kg (choline content 1650kg) is sent in the choline bitartrate reactor 5 with pump 6. 2045kg of tartaric acid solids are added to the choline hydrogen tartrate reactor 5 with a sealed hopper, the reaction pressure is 3kPaG, and the reaction temperature is 50°C. After reacting for 3 hours, feed the low-pressure steam 10 into the jacket, evaporate after 1 hour , then feed circulating water to cool down, and after being cooled to 45°C, the material is put into the centrifuge 12, and the solid material is sent to the drum dryer 13 for drying after the centrifugation, so as to obtain 3450kg of finished product choline bitartrate.

[0044] In the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com