Flexible nano-porous/amorphous composite material for hydrogen production by electrolyzing water and preparation method thereof

An amorphous composite material, nanoporous technology, applied in the direction of electrode shape/type, electrode, electrolysis process, etc., can solve the problems of insufficient catalytic activity and low specific surface area of the strip, and achieve good mechanical bending flexibility and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

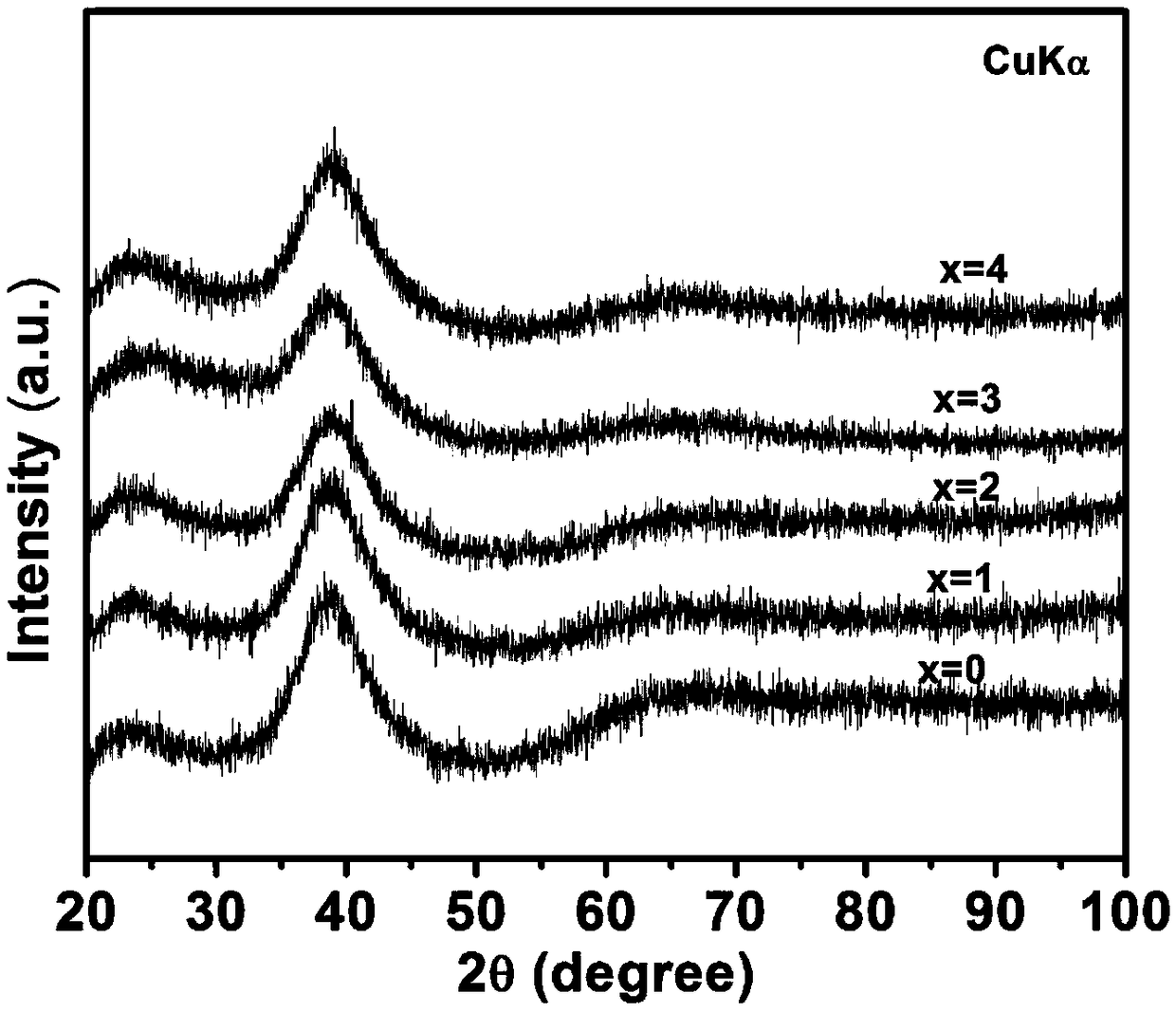

[0031] With Ni 40 Zr 40 Ti 20-x Pt x (x=0, x=1, x=2, x=3 and x=4) are used as the nominal composition of the precursor alloy, and the required elements are weighed and proportioned, and the pure elements (Ni 99.99 wt%, Zr 99.99wt%, Pt99.99wt%), converted into mass (5g) according to the atomic percentage of the alloy and weighed, and then adopting the method of high-purity argon atmosphere vacuum arc melting to obtain Ni 40 Zr 40 Ti 20-x Pt x(x=0, x=1, x=2, x=3 and x=4) master alloy button ingots are smelted for 3 to 4 times to ensure uniform composition of the master alloy ingots.

[0032] Ni 40 Zr 40 Ti 20-x Pt x (x=0, x=1, x=2, x=3 and x=4) the alloy ingot is heated and melted by induction, and then the molten metal liquid rises slowly so that it touches the tip of the high-speed rotating water-cooled copper roller, and the metal liquid is Rapidly flung out and rapidly cooled to prepare Ni 40 Zr 40 Ti 20-x Pt x (x=0, x=1, x=2, x=3 and x=4) alloy wires, the dia...

Embodiment 2

[0034] With Ni 40 Zr 40 Ti 20-x Pt x (x=0, x=1, x=2, x=3 and x=4) are used as the nominal composition of the precursor alloy, and the required elements are weighed and proportioned, and the pure elements (Ni 99.99 wt%, Zr 99.99wt%, Pt99.99wt%), converted into mass (5g) according to the atomic percentage of the alloy, and then adopting the method of high-purity argon atmosphere vacuum arc melting to obtain Ni with different precious metal contents 40 Zr 40 Ti 20-x Pt x (x=1, x=2, x=3 and x=4) master alloy button ingots are smelted 3 to 4 times to ensure uniform composition of the master alloy ingots.

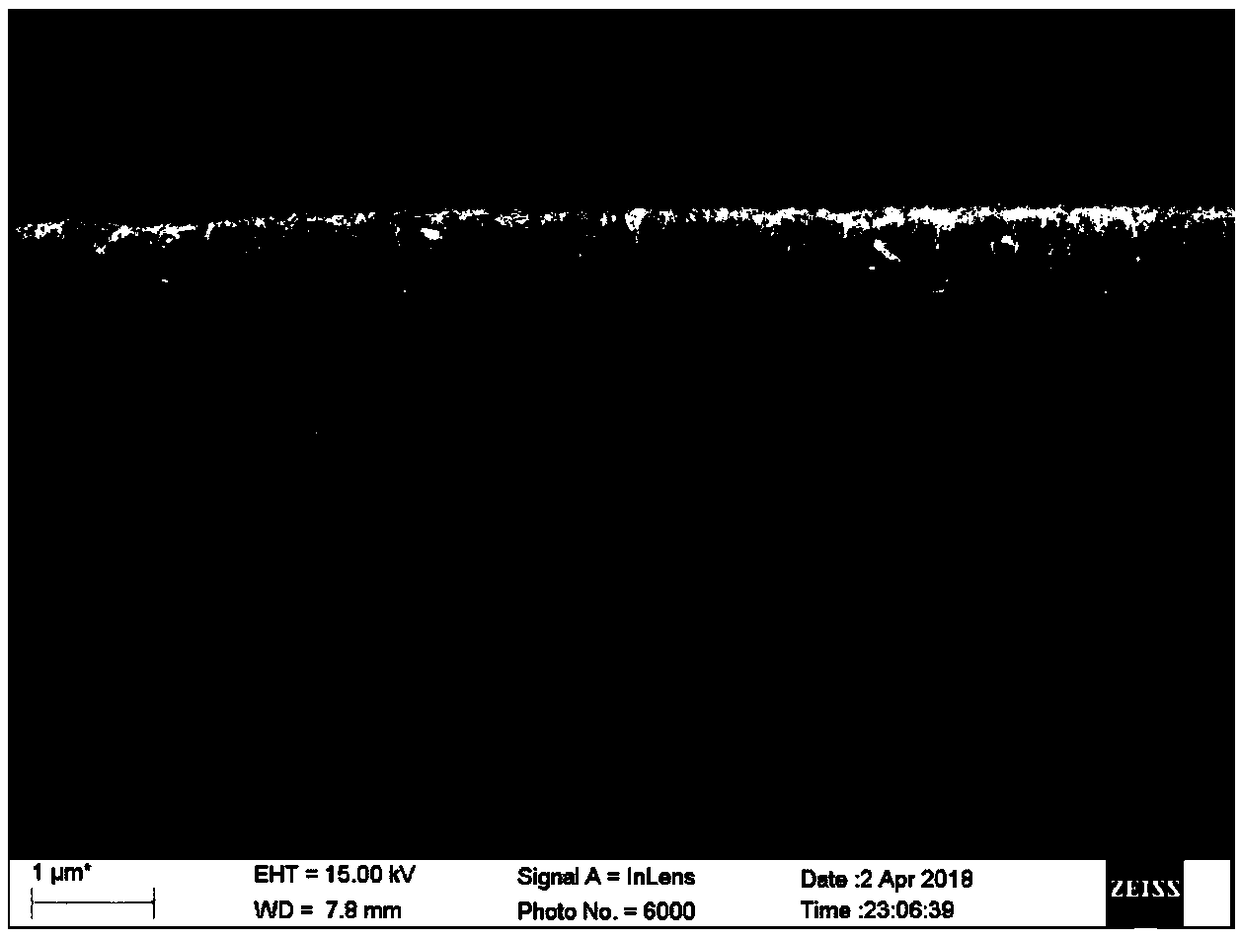

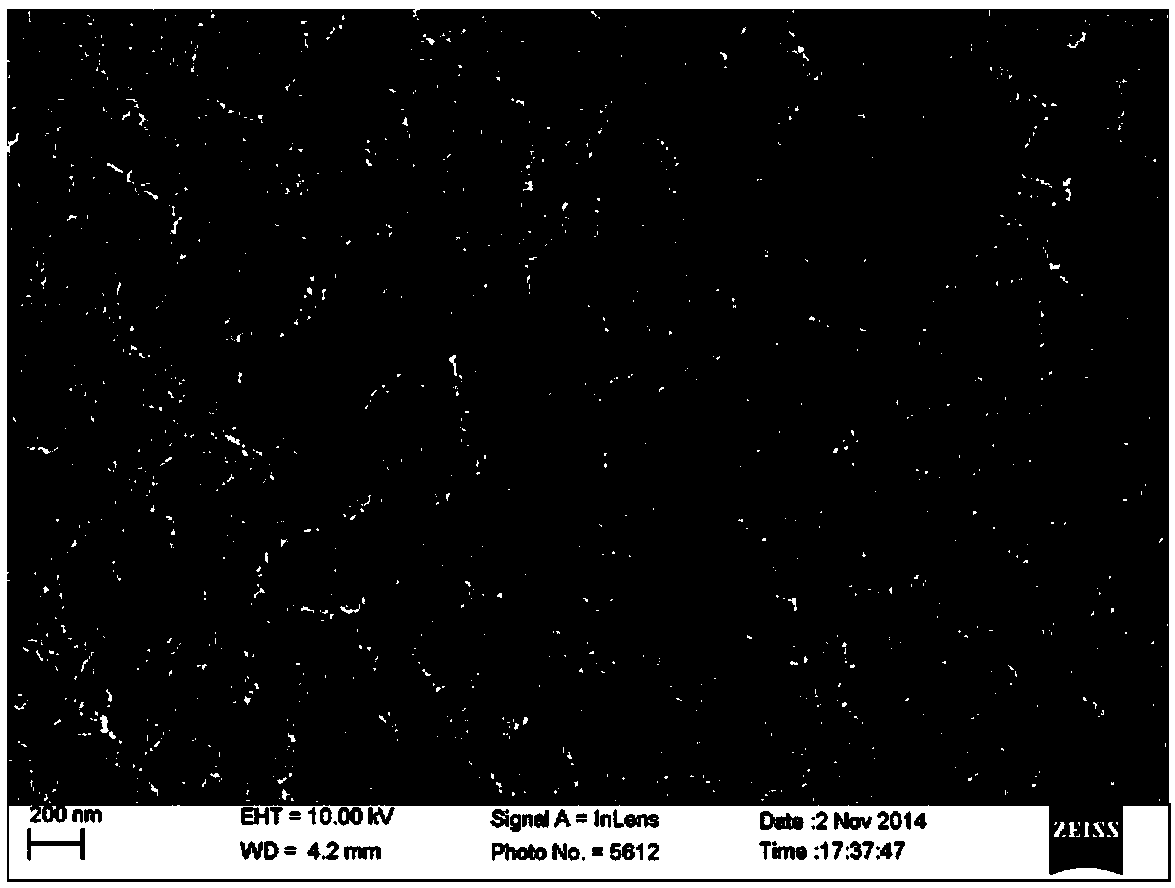

[0035] The master alloy ingot is re-melted by induction heating with a medium-frequency power supply using a vacuum stripping device, and is continuously and rapidly sprayed onto a water-cooled rotating copper roller under the action of high-purity argon with a pressure of about 0.2MPa to prepare Ni 40 Zr 40 Ti 20-x Pt x (x=0, x=1, x=2, x=3 and x=4) thin alloy strips, t...

Embodiment 3

[0038] With Ni 40 Zr 40 Ti 20-x Au x (x=1, x=2, x=3 and x=4) are used as the nominal composition of the precursor alloy, and the required elements are weighed and proportioned, and the pure elements (Ni 99.99wt%, Zr 99.99wt%, Au99.99wt%), converted into mass (5g) according to the atomic percentage of the alloy, and then adopting the method of high-purity argon atmosphere vacuum arc melting to obtain Ni with different precious metal contents 40 Zr 40 Ti 20-x Au x (x=1, x=2, x=3 and x=4) master alloy button ingots are smelted 3 to 4 times to ensure uniform composition of the master alloy ingots.

[0039] The master alloy ingot is re-melted by induction heating with a medium-frequency power supply using a vacuum stripping device, and is continuously and rapidly sprayed onto a water-cooled rotating copper roller under the action of high-purity argon with a pressure of about 0.2MPa to prepare Ni 40 Zr 40 Ti 20-x Pt x (x=1, x=2, x=3 and x=4) thin alloy strips, the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com