Flexible iron niobate nanowire array electrode and preparation method and application thereof

A technology of nanowire arrays and array electrodes, which is applied in the direction of active material electrodes, negative electrodes, battery electrodes, etc., can solve the problems of unsuccessful preparation of ferric niobate materials, and achieve good electron conduction, good reproducibility, The effect of shortening the diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example shows a preparation method of a flexible iron niobate nanowire array electrode and its application in sodium ion batteries.

[0031] Proceed as follows:

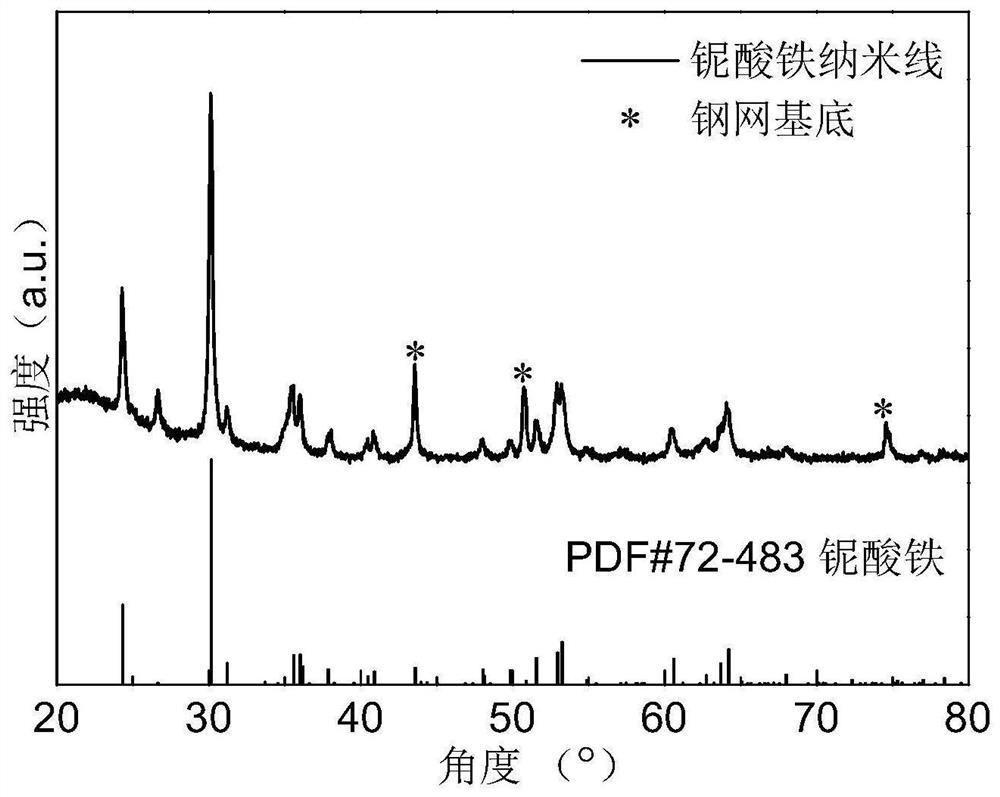

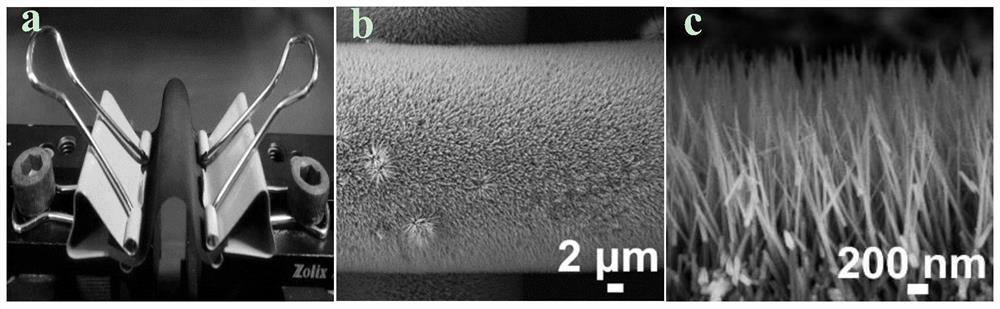

[0032] (1) Place the stainless steel mesh in absolute ethanol to ultrasonically remove surface impurities and then dry it for use; (2) Mix 0.6g niobium pentachloride, 0.9g hydrofluoric acid (mass percentage concentration 40%), and 3mL deionized water , 60mL of absolute ethanol are mixed evenly and then moved to an autoclave with a polytetrafluoroethylene substrate, then place the stainless steel mesh in step (1), and cool to room temperature after reacting at 200°C for 16h; (3) put the step ( The material obtained in 2) was heated in a high-purity argon atmosphere at a rate of 5° C. / min to 700° C. for 3 hours, and then an iron niobate nanowire array electrode was obtained. figure 1 The X-ray diffraction (XRD) phase spectrum of the product is shown. It can be seen from the figure that the diffraction peak...

Embodiment 2

[0038] This example shows a preparation method of a flexible iron niobate nanowire array electrode and its application in sodium ion batteries.

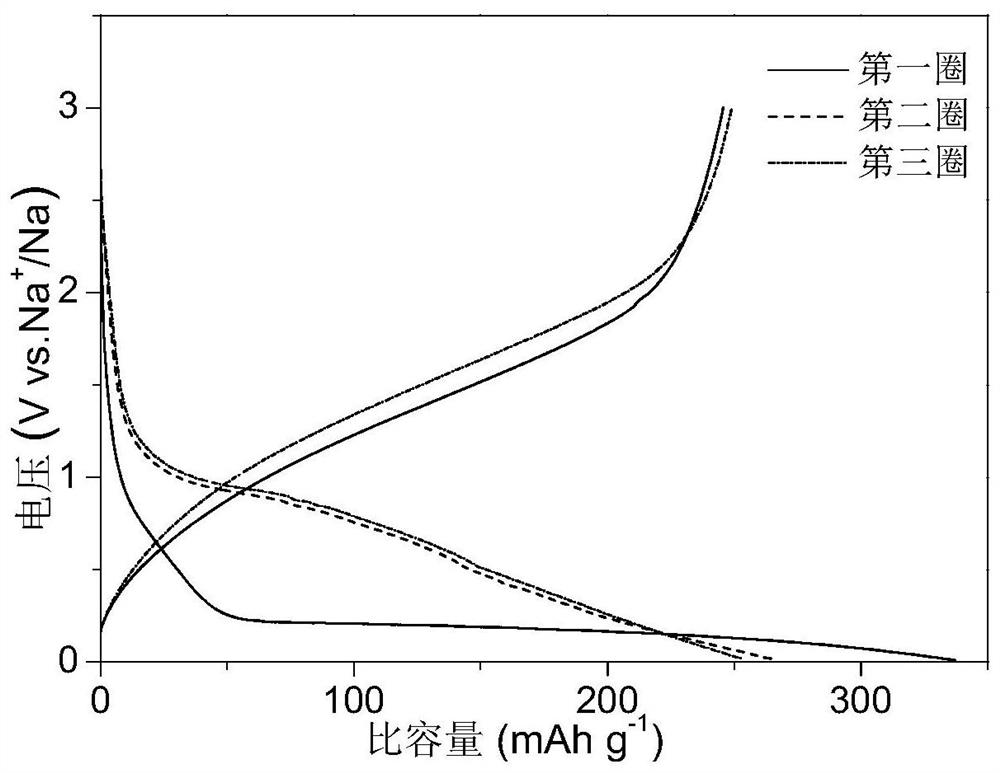

[0039](1) Place the stainless steel mesh in absolute ethanol to ultrasonically remove surface impurities and dry it for use; (2) Mix 0.8g niobium pentachloride, 1.1g hydrofluoric acid (40% by mass percentage concentration), 4.0mL deionized Mix water and 80mL of absolute ethanol evenly, then move to an autoclave with a polytetrafluoroethylene substrate, place the stainless steel mesh in step (1), react at 200°C for 16h, and then cool to room temperature; (3) ( The material obtained in 2) was heated in a high-purity argon atmosphere at a rate of 5° C. / min to 700° C. for 3 hours, and then an iron niobate nanowire array electrode was obtained. Cut the obtained iron niobate material into 1×1cm 2 The electrode sheet is used as the negative electrode material of the sodium ion battery, with 1mol / L NaClO 4 / EC (ethylene carbonate) / PC (prop...

Embodiment 3

[0042] This example shows a preparation method of a flexible iron niobate nanowire array electrode and its application in sodium ion batteries.

[0043] (1) Place the stainless steel mesh in absolute ethanol to ultrasonically remove surface impurities and then dry it for use; (2) Mix 0.6g niobium pentachloride, 0.9g hydrofluoric acid (mass percentage concentration 40%), and 3mL deionized water , 60mL of absolute ethanol are mixed evenly and then moved to an autoclave with a polytetrafluoroethylene substrate, then place the stainless steel mesh in step (1), and cool to room temperature after reacting at 210°C for 18h; (3) put the step ( The material obtained in 2) was heated up to 700° C. for 3 hours at a rate of 5° C. / min in a high-purity argon atmosphere to obtain an iron niobate nanowire array material.

[0044] According to XRD analysis, the prepared material is basically consistent with the standard card (PDF#72-483). It can be seen from the SEM characterization that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com