Boron-doped graphene/polyaniline composite aerogel and preparation method thereof

A composite airgel and graphene technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of not having compression recovery performance and compressible supercapacitors, and achieve good compression recovery performance, structural enhancement, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A boron-doped graphene / polyaniline composite airgel, comprising the steps of:

[0029] 1) 20 μL of aniline and 20 μL of a sodium tetraborate solution with a concentration of 20 mg / mL were added to 25 mL of a graphene oxide solution with a concentration of 2 mg / mL;

[0030] 2) The above mixed solution was subjected to a hydrothermal reaction at 80°C for 15 hours to obtain a composite hydrogel;

[0031] 3) Soak the obtained composite hydrogel in ethanol / deionized aqueous solution with a volume ratio of 1:5 for dialysis for 8 hours, and then freeze at -15°C for 8 hours;

[0032] 4) The lyophilized composite gel was naturally air-dried at 15°C for 48 hours to obtain the boron-doped graphene / polyaniline composite airgel.

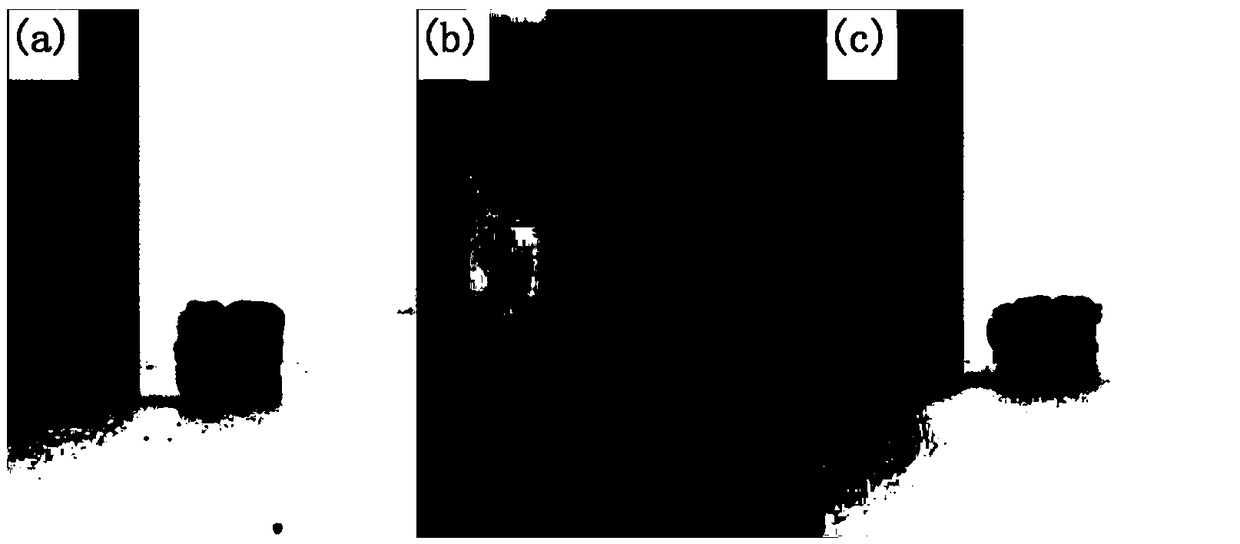

[0033] figure 1 The obtained boron-doped graphene / polyaniline composite airgel of this embodiment is a schematic diagram of the state before bearing 500g weight, when bearing 500g weight and after removing 500g weight; it can be seen from the figure that...

Embodiment 2

[0035] A boron-doped graphene / polyaniline composite airgel, comprising the steps of:

[0036] 1) Add 110 μL of aniline and 50 μL of sodium tetraborate solution with a concentration of 50 mg / mL into 30 mL of graphene oxide solution with a concentration of 4 mg / mL, respectively;

[0037] 2) The above mixed solution was subjected to a hydrothermal reaction at 120°C for 14 hours to obtain a composite hydrogel;

[0038] 3) The obtained composite hydrogel was soaked in ethanol / deionized aqueous solution with a volume ratio of 1:200 for dialysis for 9 hours, and then frozen at -10°C for 9 hours;

[0039] 4) After the lyophilized composite gel was naturally air-dried at 25° C. for 24 hours, a boron-doped graphene / polyaniline composite airgel was obtained.

[0040] After testing, the boron-doped graphene / polyaniline composite airgel obtained in this example can exhibit good compression recovery performance.

Embodiment 3

[0042] A boron-doped graphene / polyaniline composite airgel, comprising the steps of:

[0043] 1) 80 μL of aniline and 60 μL of sodium tetraborate solution with a concentration of 40 mg / mL were added to 30 mL of graphene oxide solution with a concentration of 4 mg / mL;

[0044] 2) The above mixed solution was subjected to a hydrothermal reaction at 100°C for 15 hours to obtain a composite hydrogel;

[0045] 3) Soak the obtained composite hydrogel in ethanol / deionized aqueous solution with a volume ratio of 1:80 for dialysis for 4 hours, and then freeze at -10°C for 24 hours;

[0046] 4) After the lyophilized composite gel was naturally air-dried at 40° C. for 24 hours, a boron-doped graphene / polyaniline composite airgel was obtained.

[0047] After testing, the boron-doped graphene / polyaniline composite airgel obtained in this example can exhibit good compression recovery performance.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap