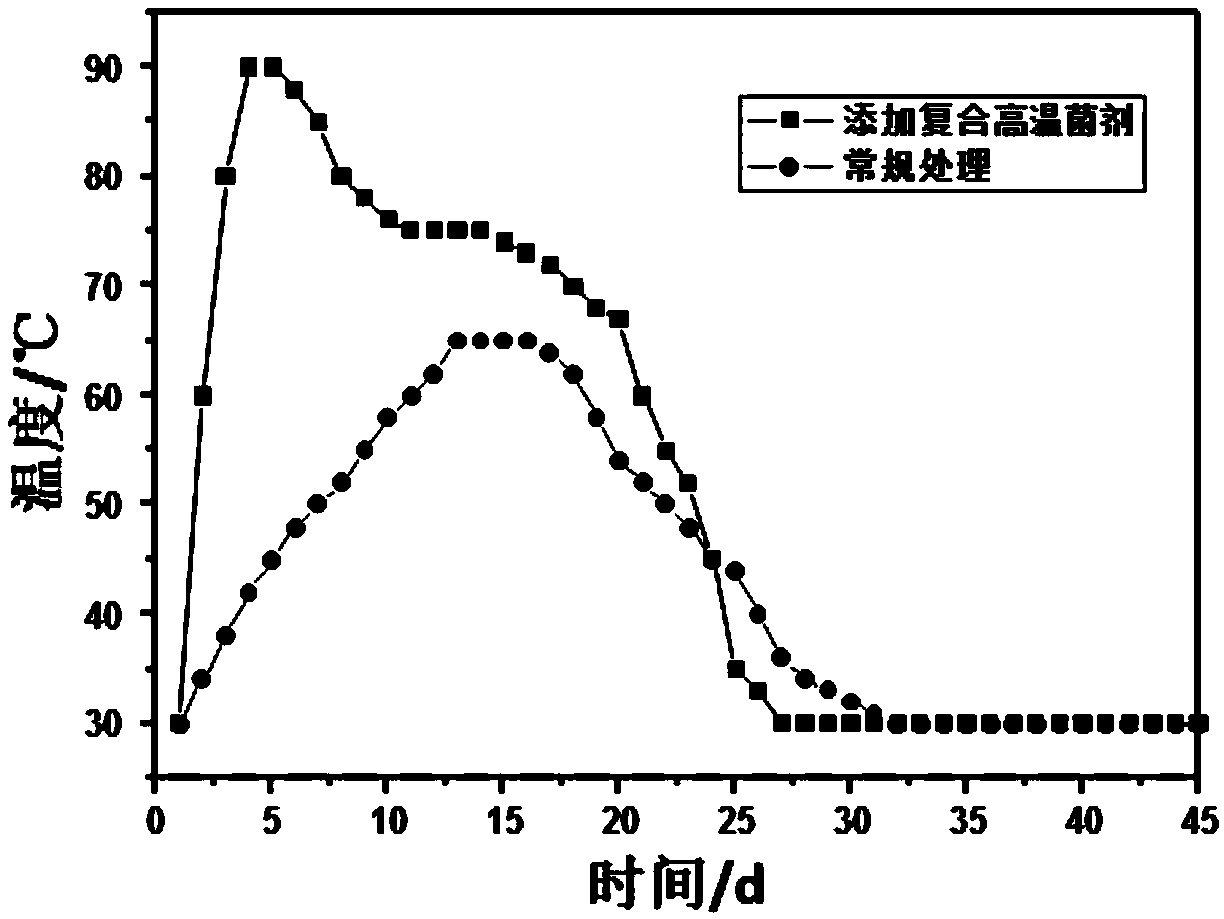

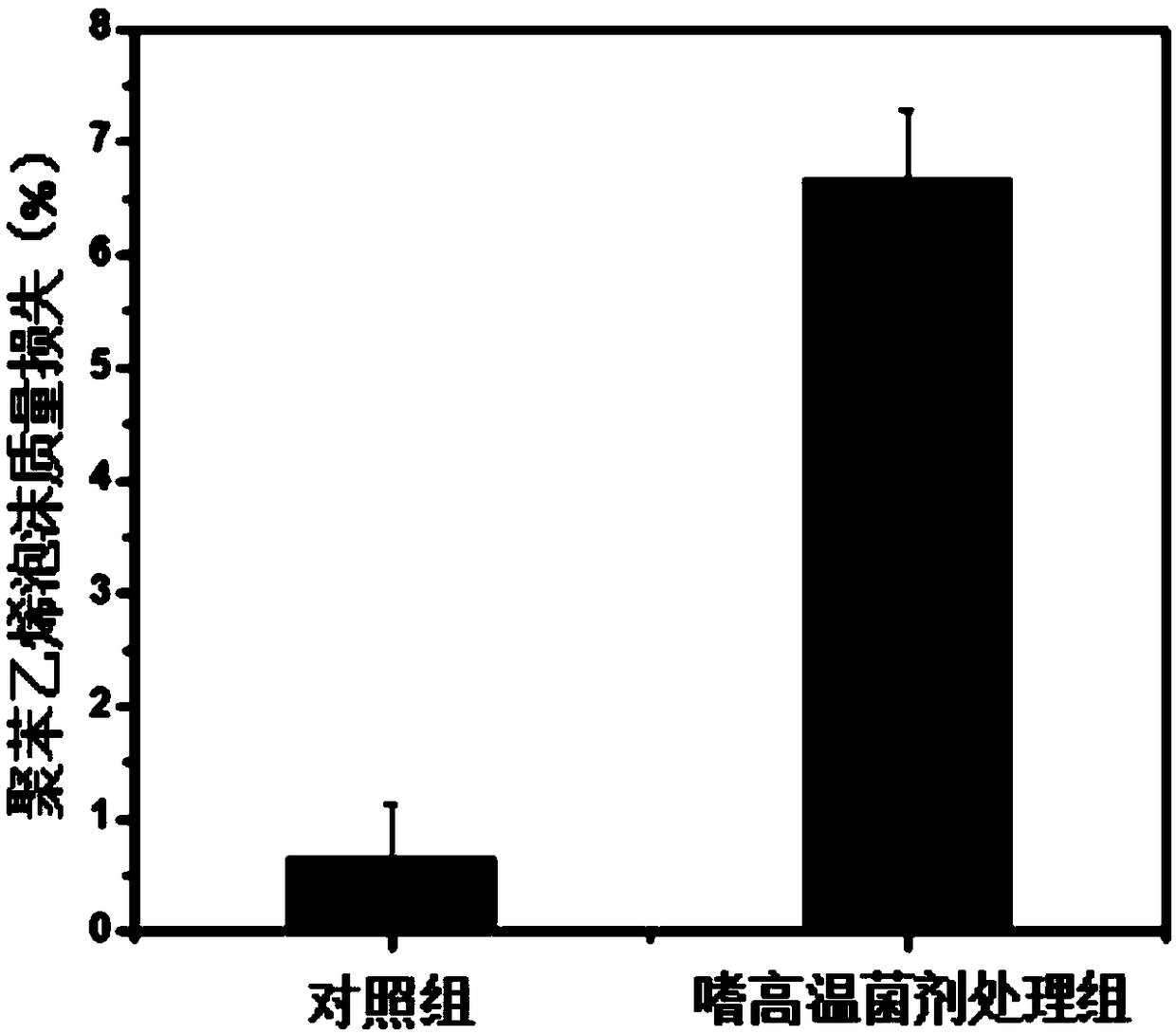

Composite thermophilic microbial agent and method for synergistically decomposing polystyrene in composting

A compound bacterial agent, polystyrene plastic technology, applied in the field of biotechnology and environment, can solve the problems such as no, and achieve the effect of promoting degradation and accelerating oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Compound Thermophilic Bacteria

[0043] 1) According to 2%, the concentration is 10 9 Cfu / mL Thermaerobacter composti FAFU014 shake flask bacterial liquid was inoculated into the seed tank with THERMAEROBACTER TY (JCM medium 734) medium, 70-75°C, ventilation volume 20-100m 3 / h, stirring speed 180-220 rev / min, fermentation time 16 hours, obtain Thermaerobacter compostiFAFU014 seed liquid;

[0044] 2) According to 2%, the concentration is 10 9 cfu / mL Thermus thermophilus FAFU013 shake flask bacterial liquid was inoculated into the seed tank containing DSMZ Medium 74 medium, 70°C, ventilation volume 20-100m 3 / h, stirring speed 180-220 rev / min, fermentation time 16 hours, obtain Thermus thermophilus FAFU013 seed liquid;

[0045] 3) According to 2%, the concentration is 10 9 cfu / mL Geobacillus stearothermophilus FAFU011 shake flask bacterial solution was inoculated into seed tanks containing DSMZ Medium 220 medium respectively, at 60°C, with an air flow ...

Embodiment 2

[0057] Preparation of thermophilic bacteria

[0058] 1) According to the method of Example 1, respectively prepare Thermus thermophilus FAFU013 and Geobacillus stearothermophilus FAFU011 seed solution;

[0059] 2) Take the concentrated sludge of a sewage treatment plant in Fujian (see Table 3 for the basic properties of the sludge), in the fermenter, adjust the sludge to a solid content of 4%, add 0.2% foam enemy, 2g / L yeast powder , 0.5g / L ammonium chloride, 0.5g / L sucrose, 0.5g / L soluble starch, 0.3g / L potassium dihydrogen phosphate, adjust the pH to 7.0, stir well, sterilize at 100°C for 45 minutes, cool to 75°C spare;

[0060] 3) First inoculate the Thermaerobacter composti FAFU014 seed liquid into the fermentation medium at 1.5% inoculum amount, and inoculate at 75°C with an air flow of 20-100m 3 / h, stirring speed 180-220 rpm, pre-fermentation for 18 hours; then inoculate Geobacillus stearothermophilus FAFU011 seed liquid at 2.5%, control the fermentation temperature a...

Embodiment 3

[0070] Preparation of thermophilic bacteria

[0071] (1) According to the method of Example 1, respectively prepare Thermus thermophilus FAFU013 and Geobacillus stearothermophilus FAFU011 seed solutions;

[0072] (2) Take the concentrated sludge of a sewage treatment plant in Fujian (the basic properties of the sludge are shown in Table 5). In the fermenter, adjust the sludge to a solid content of 4%, add 0.2% foam enemy, 2g / L Yeast powder, 0.5g / L ammonium chloride, 0.5g / L sucrose, 0.5g / L soluble starch, 0.3g / L potassium dihydrogen phosphate, adjust the pH to 7.0, stir well, sterilize at 100°C for 45 minutes, cool to Standby at 70°C;

[0073](3) First inoculate the Thermus thermophilus FAFU013 seed liquid at 2%, control the fermentation temperature at 70°C, and carry out pre-fermentation for 16 hours; finally inoculate the Geobacillus stearothermophilus FAFU011 seed liquid at 2.5%, control the fermentation temperature at 65°C, and carry out post-fermentation for 20 hours. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com