Preparation method of protein-polyphenol-polysaccharide covalent complex and application of protein-polyphenol-polysaccharide covalent complex

A compound and protein technology, applied in applications, food science, food ingredients as emulsifiers, etc., can solve the problems of many by-products, difficult to achieve product purification, etc., to achieve simple method, good antioxidant capacity and thermal stability, The effect of improving emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

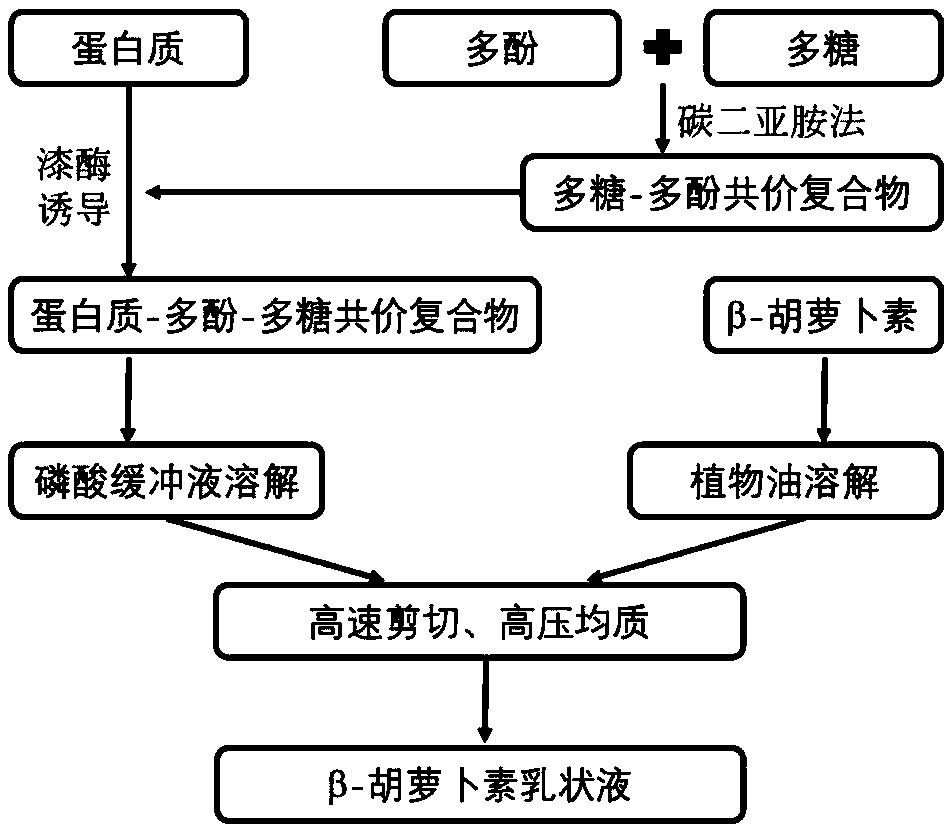

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of β-lactoglobulin-ferulic acid-chitosan covalent complex, the steps are as follows:

[0029] (1) Disperse 0.50 g of chitosan in 70 mL of deionized water, adjust the chitosan solution to pH 6.0, and swell overnight to fully dissolve it. Add 1.20g of ferulic acid, 2.38g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1.43g of N-hydroxysuccinimide into 30mL of absolute ethanol, 4 ° C and stirred for 1 h to obtain a mixed solution. The chitosan solution was added to the above mixed solution, stirred at 4° C. for 1 h, and then the temperature was raised to 25° C. and the stirring reaction was continued for 24 h. The reaction product was placed in a 12kDa dialysis bag and dialyzed with deionized water for 24 hours; then the mixed solution in the dialysis bag was centrifuged at 4500 rpm for 1 hour, and the supernatant was placed in a 12kDa dialysis bag and dialyzed with deionized water for 48 hours. Then freeze-dry to obtain the cov...

Embodiment 2

[0036] The preparation method of lactoferrin-chlorogenic acid-chitosan covalent complex, the steps are as follows:

[0037](1) Disperse 0.50 g of chitosan in 70 mL of deionized water, adjust the chitosan solution to pH 6.0, and swell overnight to fully dissolve it. Add 14.19g of chlorogenic acid, 2.38g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1.43g of N-hydroxysuccinimide into 30mL of absolute ethanol at 4°C Stir for 1 h to obtain a mixed solution. The chitosan solution was added to the above mixed solution, and stirred at 4 °C for 1 h. Subsequently, the temperature was raised to 25° C. and the stirring reaction was continued for 24 h. The reaction product was placed in a 12kDa dialysis bag and dialyzed with deionized water for 24 hours; then the mixed solution in the dialysis bag was centrifuged at 4500 rpm for 1 hour, and the supernatant was placed in a 12kDa dialysis bag and dialyzed with deionized water for 48 hours. Then freeze-dry to obtain a...

Embodiment 3

[0040] The preparation method of α-lactalbumin-chlorogenic acid-sodium alginate covalent compound, the steps are as follows:

[0041] (1) Disperse 0.50 g of sodium alginate in 70 mL of deionized water, adjust the pH of the sodium alginate solution to 6.0, and swell overnight to fully dissolve it. Add 0.88g chlorogenic acid, 0.96g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.58g N-hydroxysuccinimide to 30mL absolute ethanol, 4 ° C and stirred for 1 h to obtain a mixed solution. Sodium alginate solution was added to the above mixed solution, and stirred at 4 °C for 1 h. Subsequently, the temperature was raised to 25° C., and the stirring reaction was continued for 24 h. The reaction product was placed in a 12kDa dialysis bag and dialyzed with deionized water for 24 hours; then the mixed solution in the dialysis bag was centrifuged at 4500 rpm for 1 hour, and the supernatant was placed in a 12kDa dialysis bag and dialyzed with deionized water for 48 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com