Zeolite synthesized from fly ash and a method for treating high-concentration ammonia-nitrogen wastewater by zeolite

A fly ash and zeolite technology, applied in water/sewage treatment, chemical instruments and methods, animal husbandry wastewater treatment, etc., can solve problems such as poor denitrification effect, poor buffering capacity of high ammonia nitrogen wastewater, and inhibition of microbial activity. Achieve the effects of improving wastewater treatment efficiency, realizing resource utilization, and reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

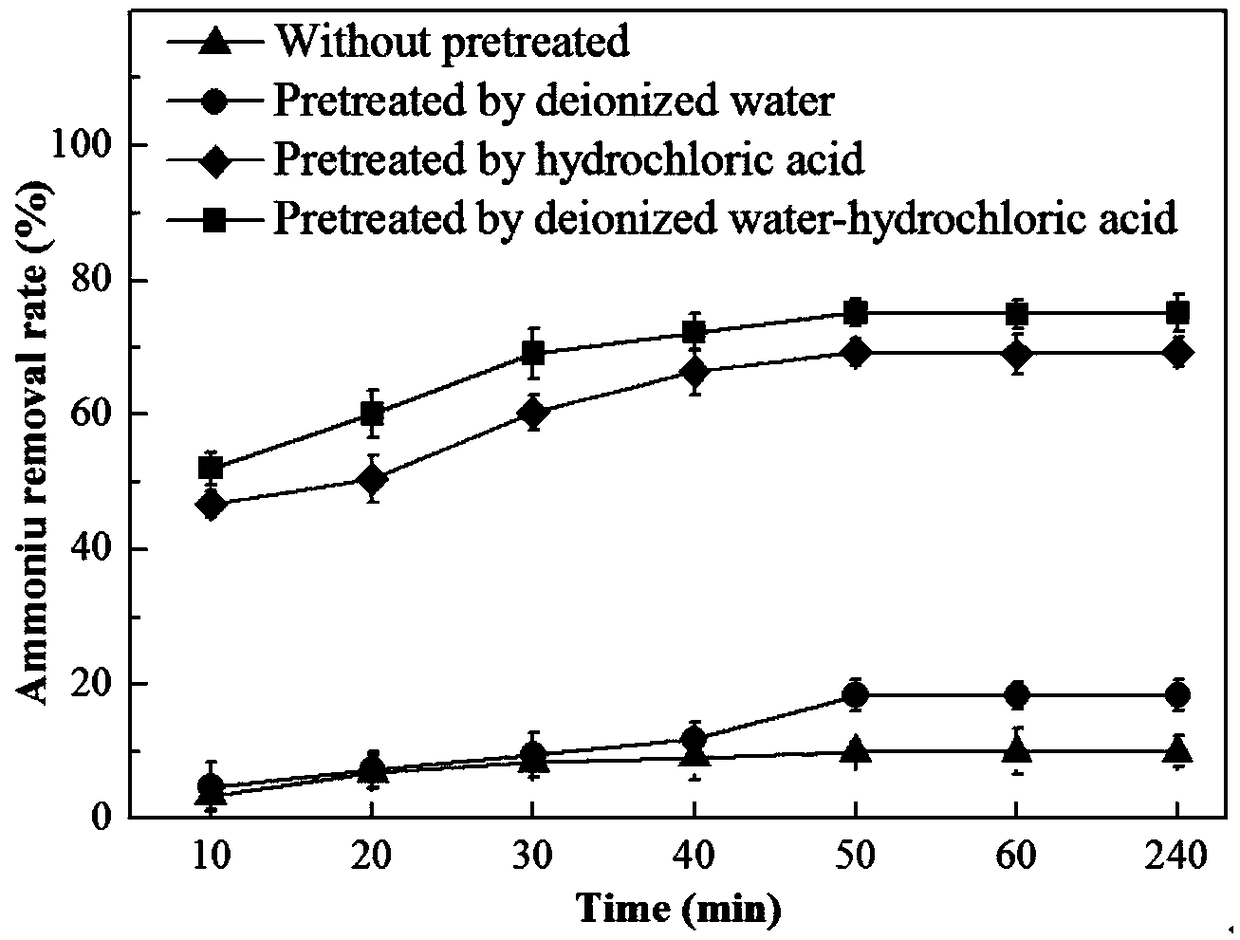

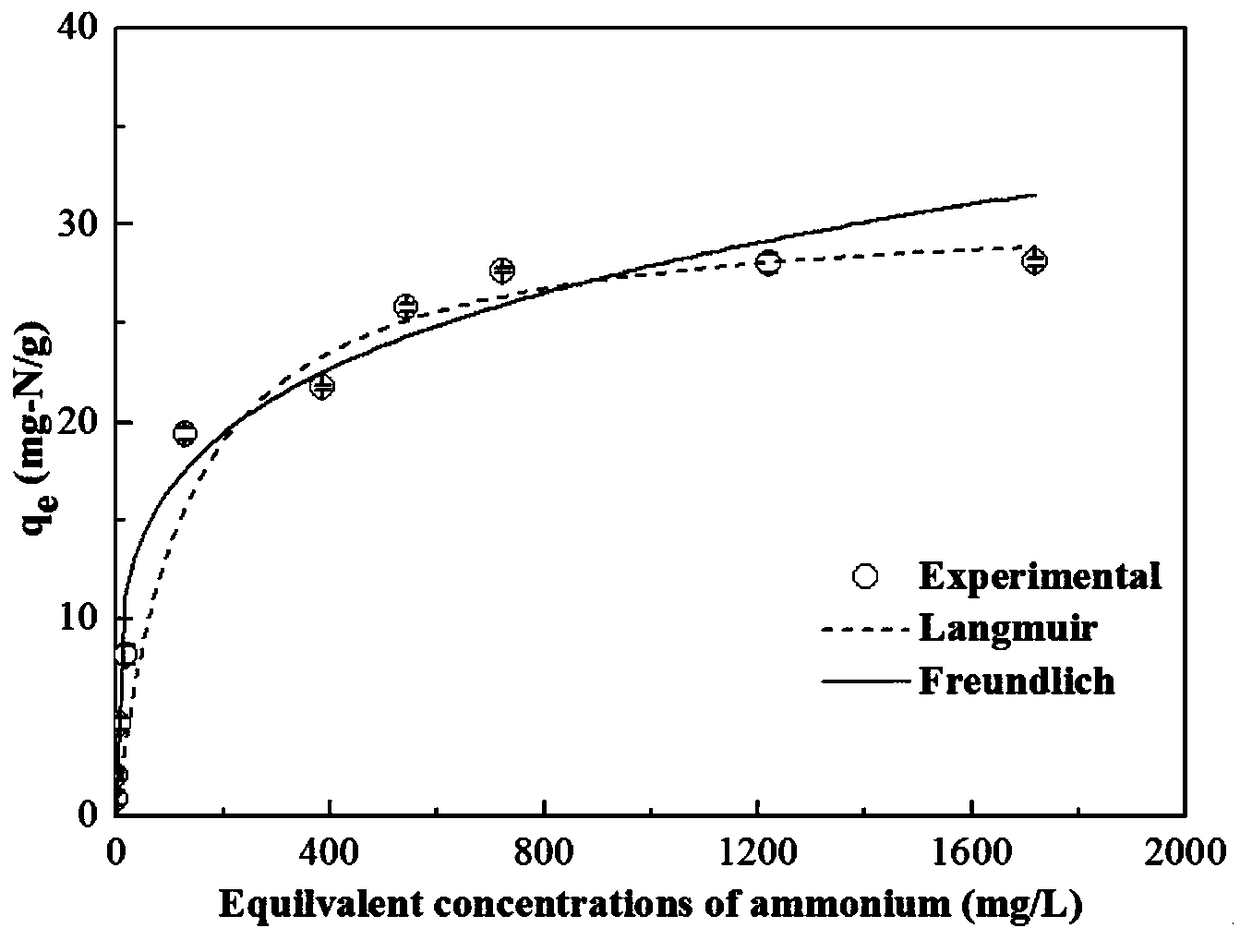

[0031] Embodiment 1: a kind of method utilizing fly ash zeolite to pretreat high-concentration ammonia nitrogen wastewater, the synthesis of its zeolite comprises the steps:

[0032] (1) Fly ash pretreatment

[0033] Mix the fly ash and deionized water in a beaker at an appropriate volume ratio evenly, then place it in a magnetic stirrer in a constant temperature water area, stir for 48 hours at 25°C and 1800r / min for water washing pretreatment. After washing with water, centrifuge for solid-liquid separation, and discard the supernatant. And use absolute ethanol to clean the centrifuged water-washed fly ash, and repeat the operation 3 times. Take the dried fly ash and sieve it in a 200-mesh standard sieve. The material that passed the sieving was the washed fly ash prepared in this experiment, which was stored in a desiccator for later use.

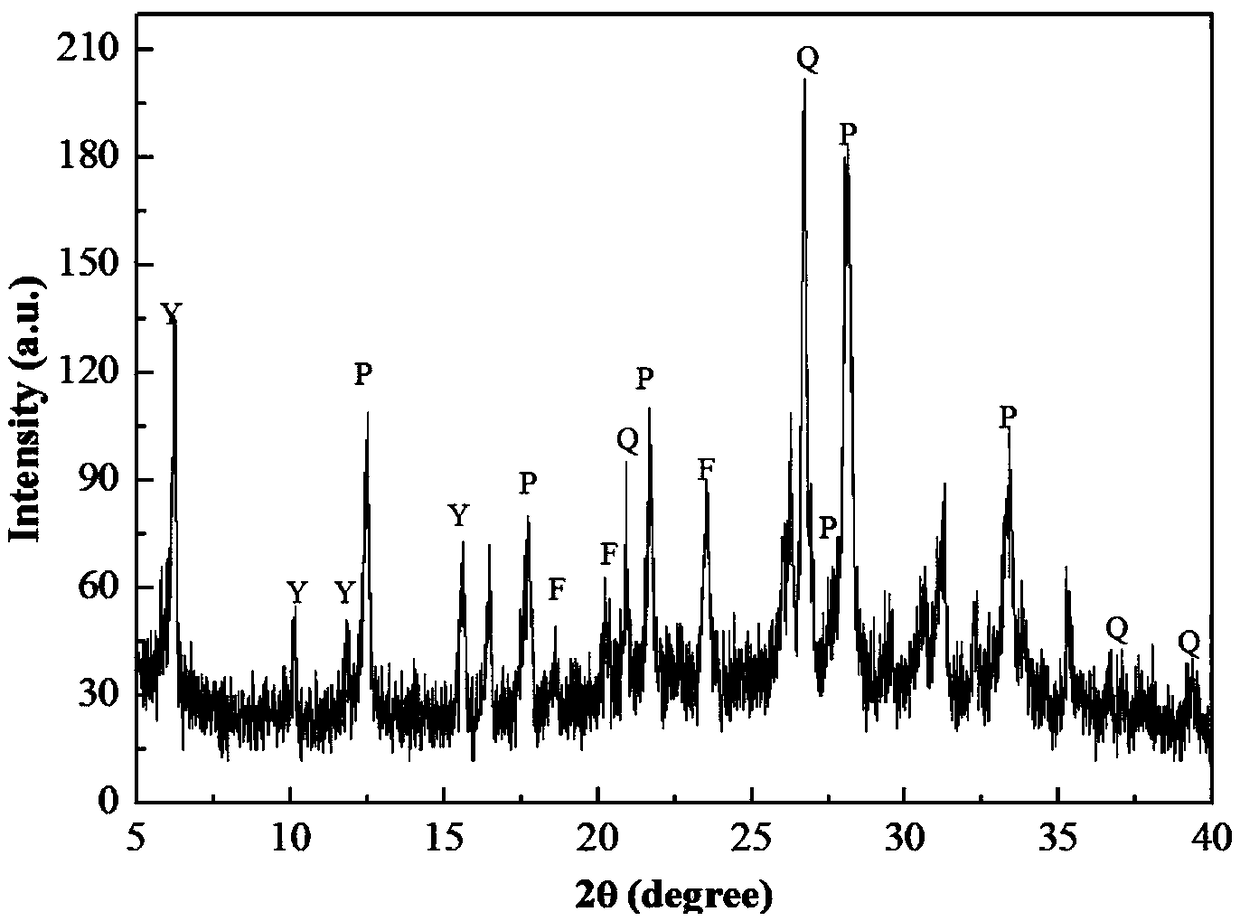

[0034] (2) Preparation of zeolite

[0035] The pretreated fly ash and 2M NaOH solution were mixed uniformly in the autoclave at a r...

Embodiment 2

[0037] Embodiment 2: a kind of method utilizing fly ash zeolite to pretreat high-concentration ammonia nitrogen wastewater, the synthesis of its zeolite comprises the steps:

[0038] (1) Fly ash pretreatment

[0039] Mix fly ash and 2mol / L HCL solution in a beaker at a volume ratio of 11:1 (V / W), then place it in a magnetic stirrer in a constant temperature water area, stir for 1 hour at 80°C and 1800r / min for pickling preprocessing. After pickling, centrifuge for solid-liquid separation and discard the supernatant. Use deionized water to clean the residual Cl- in the acid-washed fly ash, and use 0.1mol / L AgNO after centrifugation 3 Solution detection of Cl in the supernatant - content. Repeat the above operation until no Cl can be detected in the supernatant - The presence.

[0040] Thereafter, 95% absolute ethanol and acid-washed fly ash were mixed evenly and centrifuged for solid-liquid separation, and the operation was repeated 3 times. The obtained fly ash was drie...

Embodiment 3

[0042] Embodiment 3: a kind of method utilizing fly ash zeolite to pretreat high-concentration ammonia nitrogen wastewater, the synthesis of its zeolite comprises the following steps:

[0043] Mix the fly ash and deionized water in a beaker at an appropriate volume ratio, and then place it in a magnetic stirrer in a constant temperature water area, stir for 48 hours at 25°C and 180r / min for water washing pretreatment. After washing with water, centrifuge at 5000r / min for 30min for solid-liquid separation, and discard the supernatant. And use absolute ethanol to clean the centrifuged water-washed fly ash, and repeat the operation 3 times. Take the dried fly ash and sieve it in a 200-mesh standard sieve. The material that passed the sieving was the washed fly ash prepared in this experiment, which was stored in a desiccator for later use.

[0044] Mix the above-mentioned water-washed fly ash and 2mol / L HCL solution in a beaker at a volume ratio of 9:1 (V / W), then place it in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com