Method for repairing heavy metal contaminated soil by modified nanoscale zero-valent iron synergizing with microorganisms

A technology of nano-zero-valent iron and microbial remediation, applied in the restoration of polluted soil, etc., can solve the problems of enhanced adsorption, reduction and fixation of soil heavy metals, accelerated nano-iron corrosion, easy passivation of nano-zero-valent iron, etc., to achieve enhanced Dispersibility and oxidation resistance, good economic value, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

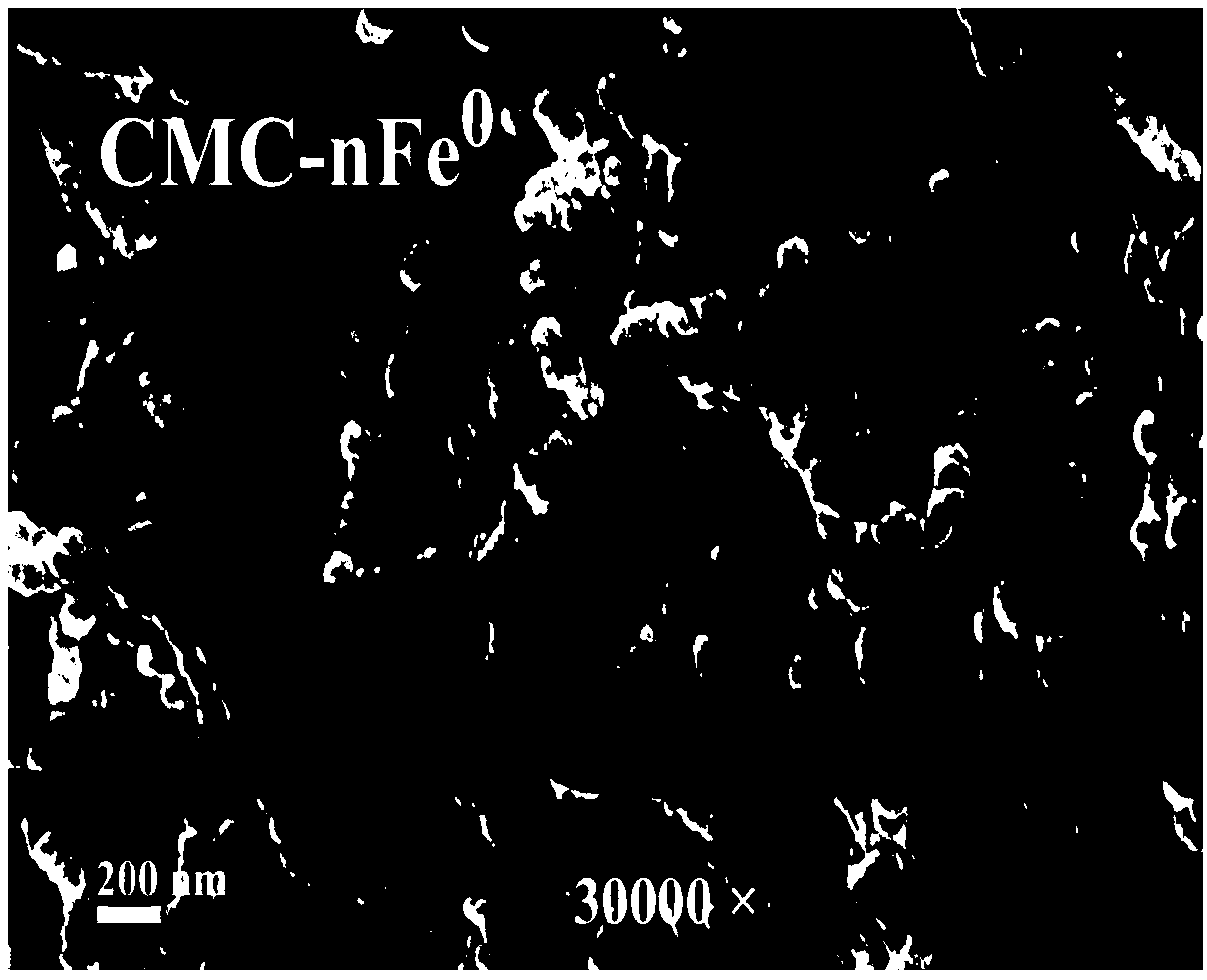

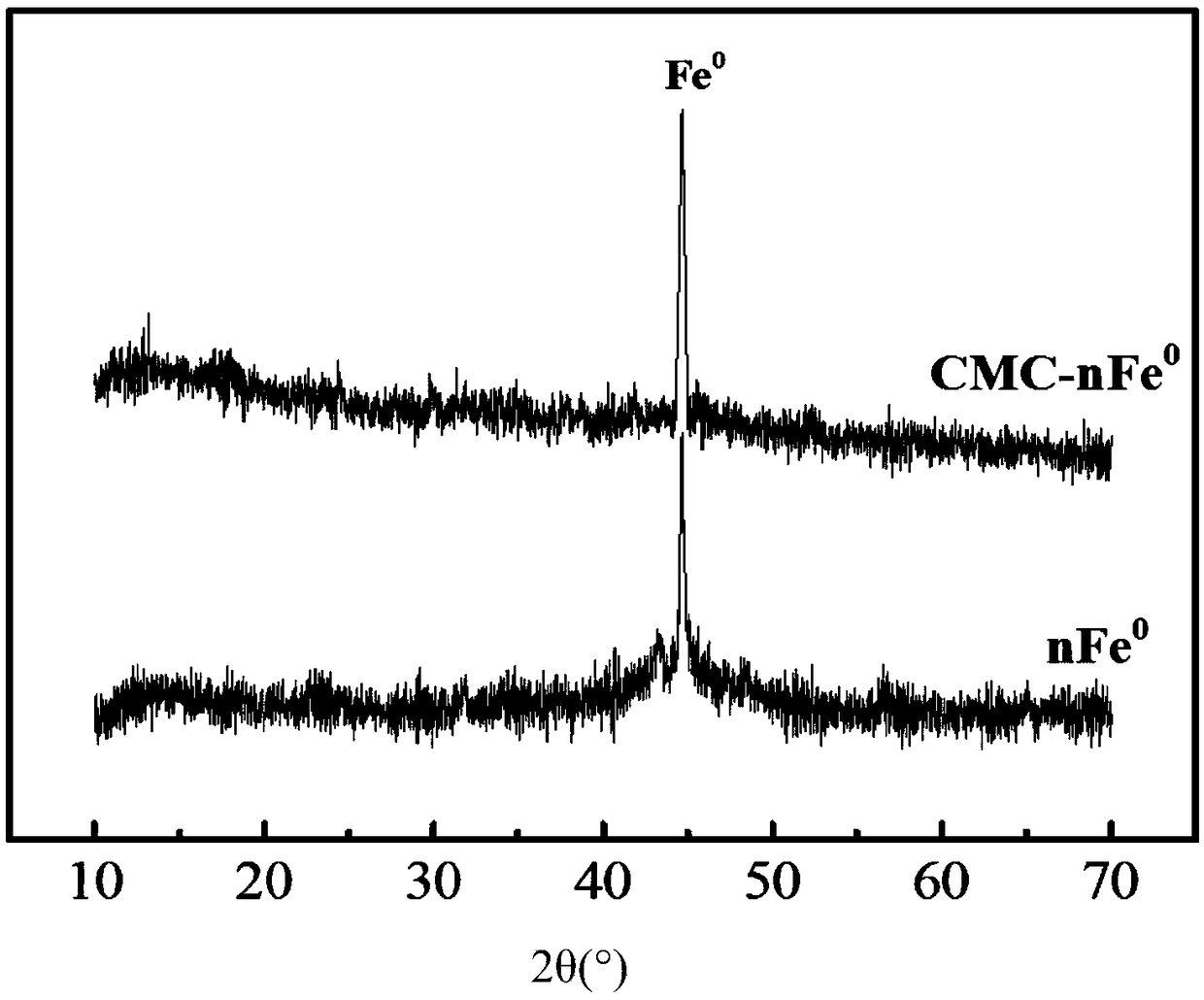

[0032] A kind of preparation method of carboxymethyl cellulose modified nano zero valent iron, it comprises the following steps:

[0033] Preparation of carboxymethyl cellulose modified nanometer zero-valent iron (CMC-nFe) by liquid phase reduction method 0 ): Under nitrogen protection, 50mL of CMC solution with a mass concentration of 0.5% and 100mL of FeSO with a concentration of 0.05mol / L 4 ·7H 2 O Stir and mix well (FeSO 4 ·7H 2 The mass ratio of O to CMC is 5.6:1); then under stirring (300r / min), add 100mL of NaBH with a concentration of 0.15mol / L dropwise at a speed of 1mL / min 4 solution until no bubbles are produced and then continue to stir for 20 minutes to ensure that the reaction is complete. After washing with absolute ethanol and deoxygenated water to neutrality, the CMC-nFe with a concentration of 1g / L is obtained. 0 The suspension is stored in a brown bottle for later use.

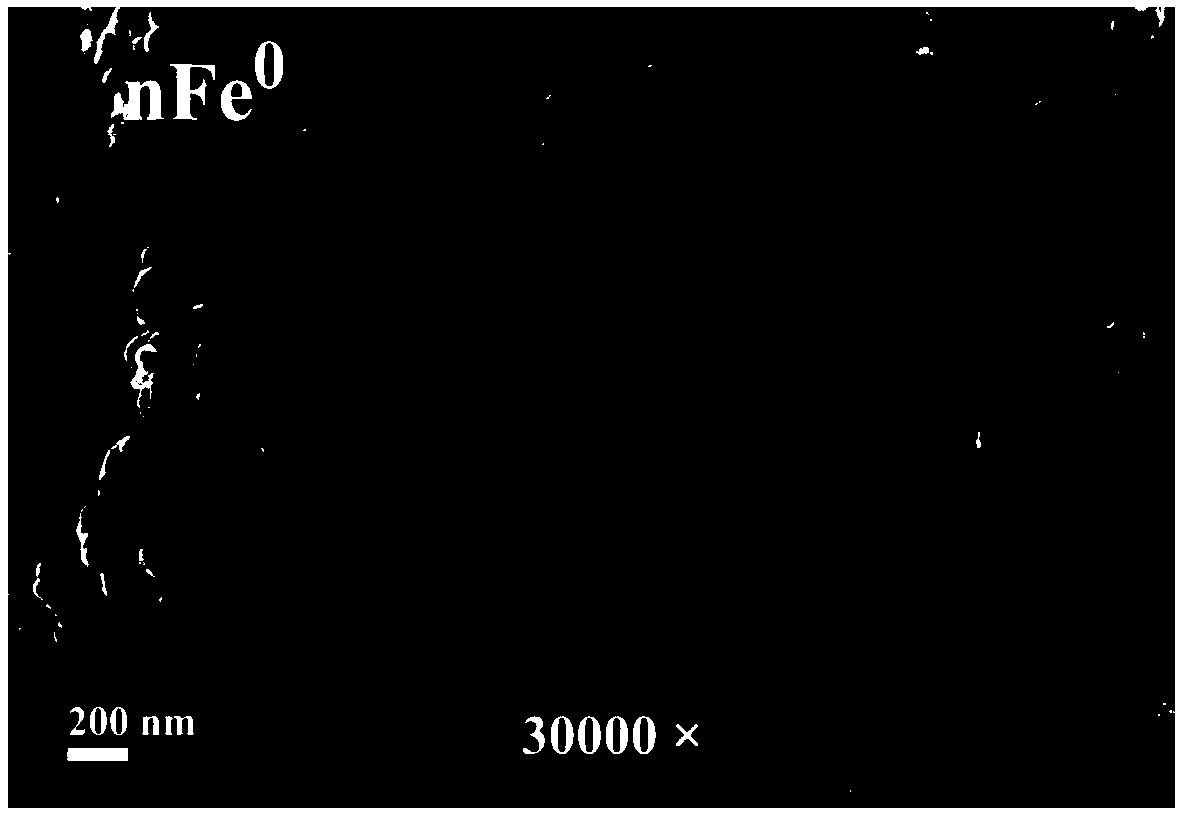

[0034] Unmodified nano zero valent iron (nFe 0 ): Using the same method as above b...

Embodiment 2

[0048] A kind of preparation method of carboxymethyl cellulose modified nano zero valent iron, it comprises the following steps:

[0049] Preparation of carboxymethyl cellulose modified nanometer zero-valent iron (CMC-nFe) by liquid phase reduction method 0 ): Under nitrogen protection, 50mL of CMC solution with a mass concentration of 0.5% and 100mL of FeSO with a concentration of 0.05mol / L 4 ·7H 2 O Stir and mix well (FeSO 4 ·7H 2 The mass ratio of O to CMC is 5.6:1); then under stirring (300r / min), add 100mL of NaBH with a concentration of 0.15mol / L dropwise at a speed of 1mL / min 4 solution until no bubbles are produced and then continue to stir for 20 minutes to ensure that the reaction is complete. After washing with absolute ethanol and deoxygenated water to neutrality, the CMC-nFe with a concentration of 1g / L is obtained. 0 The suspension is stored in a brown bottle for later use.

[0050] A method for modifying nano-zero-valent iron to cooperate with microorganism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com