A device and method for single-stage continuous preparation of carbon nanotubes

A technology of carbon nanotubes and catalysts, applied in the field of single-stage continuous preparation of carbon nanotubes, which can solve the problems of short residence time, easy agglomeration of carbon nanotubes, and low conversion rate of raw gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

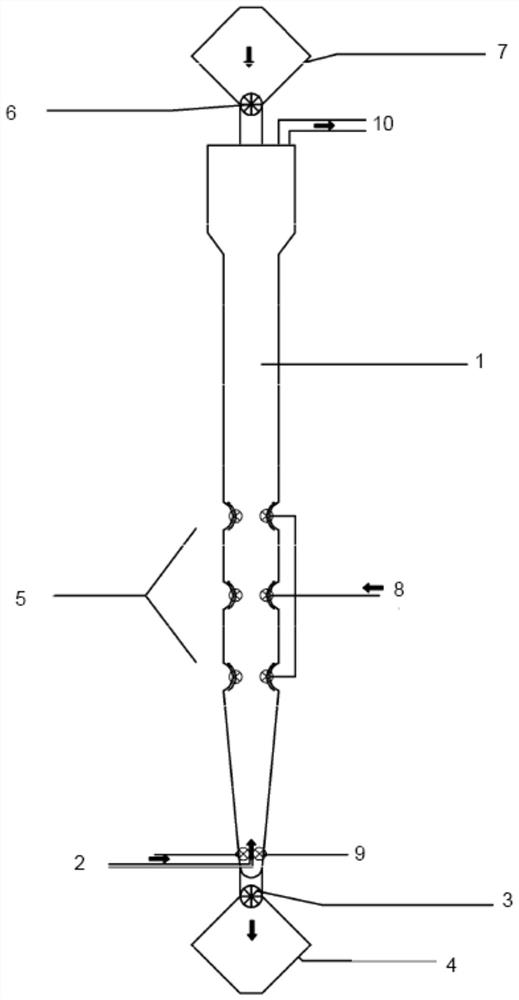

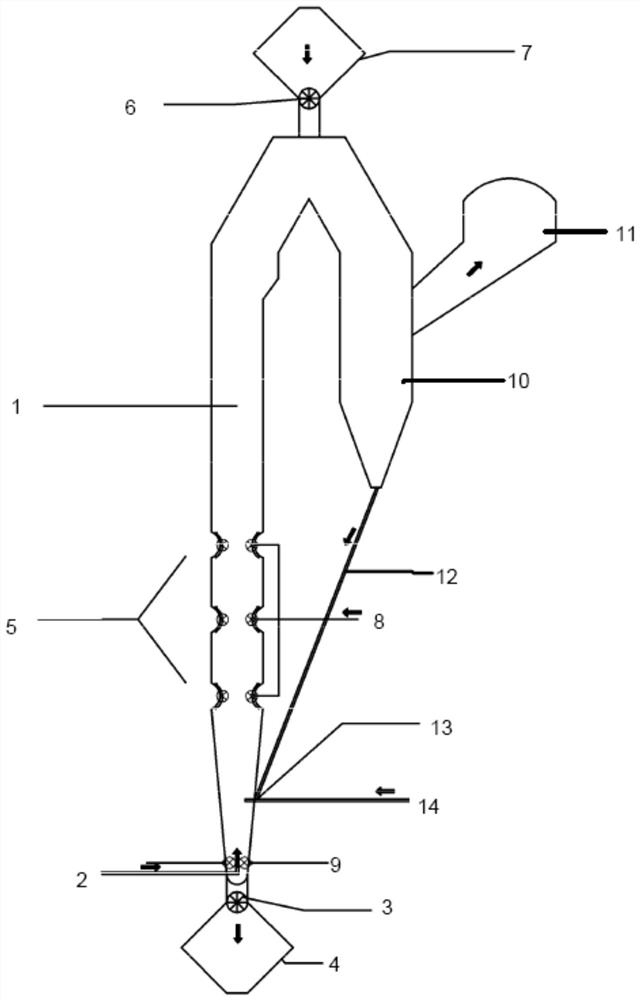

[0143] based on figure 1 In the shown reaction device, the carbon source is propylene, the catalyst is an iron-based catalyst, and the total iron content is 29.12%.

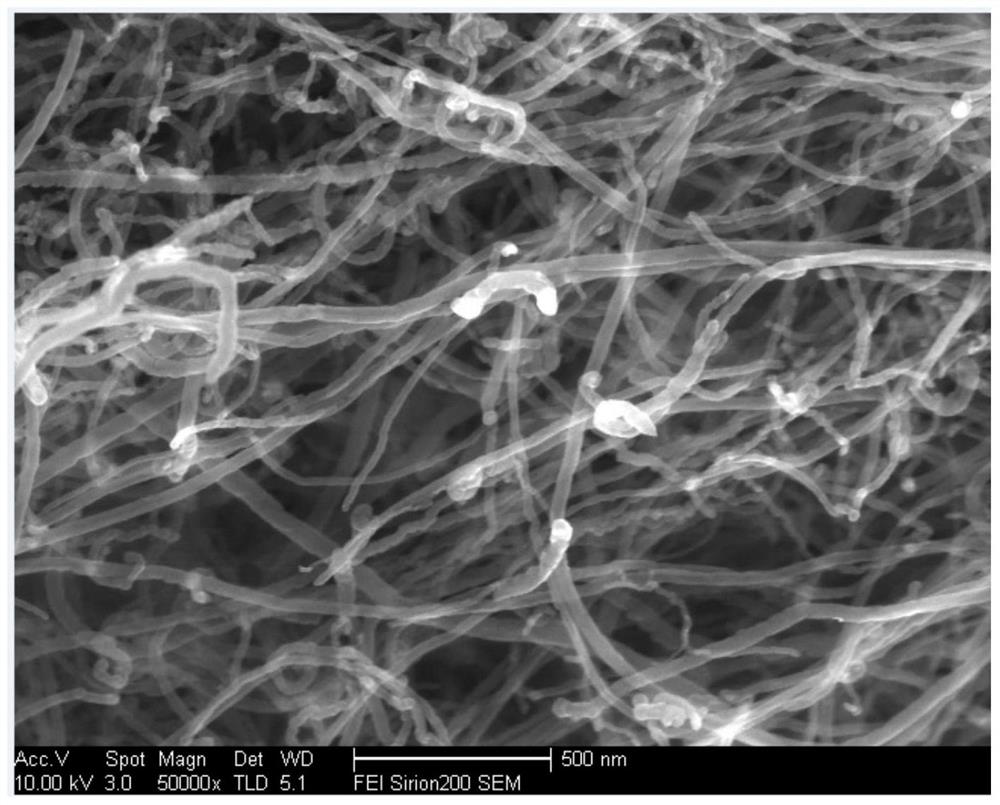

[0144] Nitrogen was introduced from the mixed gas inlet for 20 minutes before the reaction, N 2 The flow rate is 8.0m / s, and the temperature of the main reactor is raised to 650°C under the protection of nitrogen. The catalyst feeding port starts to feed continuously and stably 60g / h, and the mixed gas of propylene: nitrogen 1:2 is passed into the reactor from the mixed gas inlet, and the gas flow rate is 1.2m / s, forming a fluidized state; the main reactor is annular The air curtain at the variable diameter and the bottom is opened for pulse purge, the exhaust lock valve is open, and the continuous production is 3 hours, producing 9.25kg of carbon nanotubes. The SEM picture of carbon nanotubes is as follows image 3 shown.

[0145] The parameters and properties of the obtained carbon nanotube products are as f...

Embodiment 2

[0148] based on figure 1 In the preparation device shown, the carbon source is propane, the catalyst is a nickel-based catalyst, the total nickel content is 9.15%, and the iron content is 31%.

[0149] Nitrogen was passed through the mixed gas inlet for 30 minutes before the reaction, N 2 The flow rate is 8.0m / s, and the temperature of the main reactor is raised to 730°C under the protection of nitrogen. The catalyst feeding port starts to feed 30g / h continuously, and the mixed gas of propane: nitrogen 1:2.5 is passed into the reactor from the mixed gas inlet, and the gas flow rate is 0.9m / s, forming a fluidized state; the main reactor is annular The air curtain at the variable diameter and the bottom is opened for pulse purge, the exhaust lock valve is open, and the continuous production is 2 hours, the production of carbon nanotubes is 3.51kg. The SEM picture of carbon nanotubes is as follows Figure 4 shown.

[0150] The parameters and properties of the obtained carbon n...

Embodiment 3

[0153] based on figure 1 In the preparation device shown, the carbon source is ethylene, and red cobalt catalyst is used, and the total cobalt content is 36.39%.

[0154] Nitrogen was passed through the mixed gas inlet for 60 minutes before the reaction, N 2 The flow rate is 8.0m / s, and the temperature of the main reactor is raised to 690°C under the protection of nitrogen. The catalyst feeding port starts to feed continuously and stably 50g / h, and the mixed gas of ethylene: nitrogen of 1:3 is passed into the reactor from the mixed gas inlet, and the gas flow rate is 0.8m / s, forming a fluidized state; the main reactor is annular The air curtain at the variable diameter and the bottom is opened for pulse purge, the exhaust lock valve is open, and the continuous production is 3 hours, producing 4.57kg of carbon nanotubes. The SEM picture of carbon nanotubes is as follows Figure 5 shown.

[0155] The parameters and properties of the obtained carbon nanotube product are as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com