Aluminum molybdate-based microwave dielectric composite ceramic and preparation method thereof

A technology of microwave dielectric and composite ceramics, which is applied in the field of aluminum molybdate-based microwave dielectric composite ceramics and its preparation, can solve problems such as low dielectric constant, achieve low dielectric constant, no abnormal growth of crystal grains, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The corresponding preparation method of aluminum molybdate-based microwave dielectric composite ceramics proposed by the present invention comprises the following steps and contents:

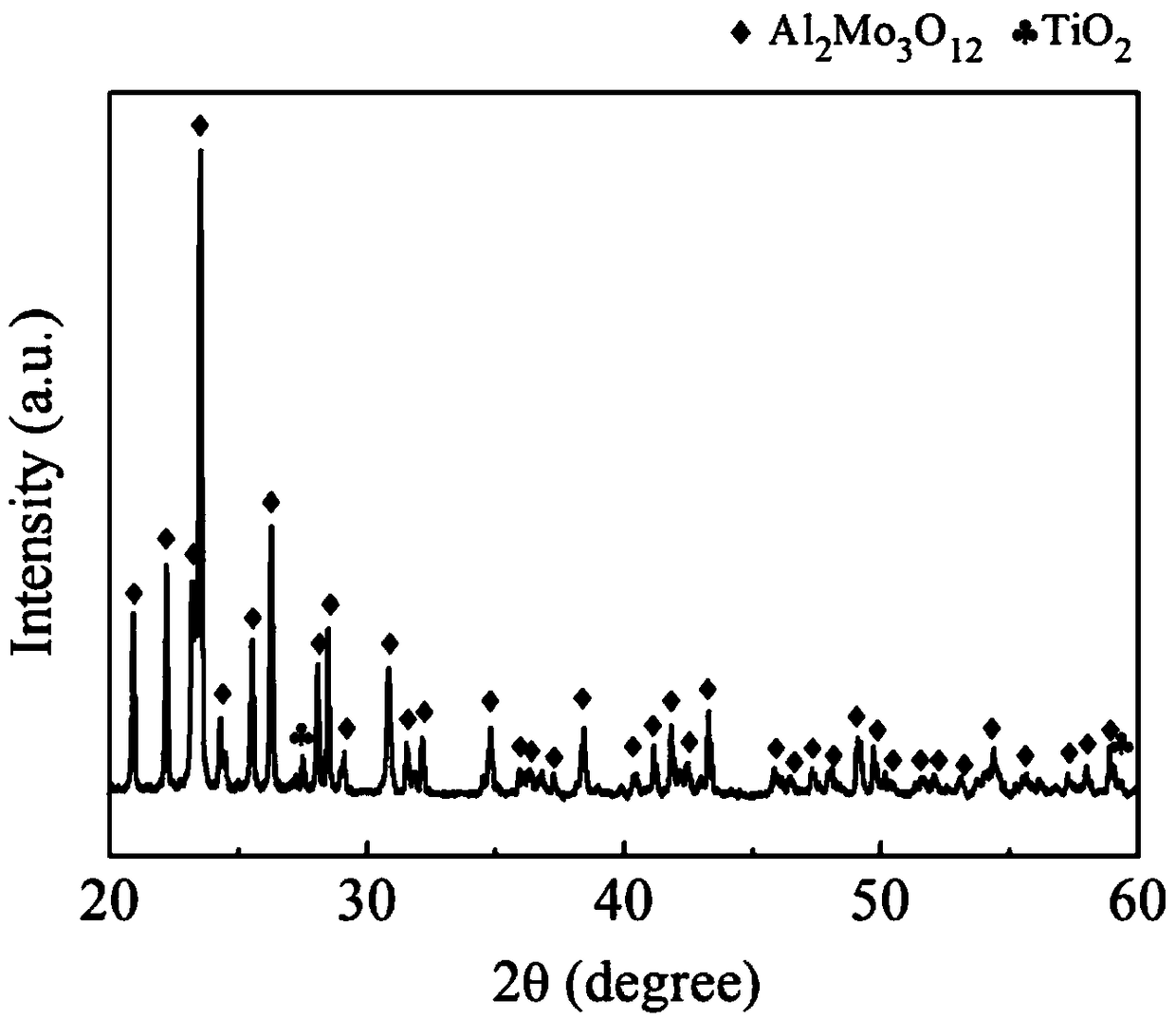

[0041] (1) First, according to Al 2 Mo 3 o 12 The stoichiometric ratio weighs high-purity Al 2 o 3 and MoO 3 powder; then, put it into the ball mill tank, and add deionized water as solvent, high wear-resistant ZrO 2 The balls are balls for ball milling; after the obtained slurry is dried, it is put into a muffle furnace for calcination to obtain the Al 2 Mo 3 o 12 Precursor. spare.

[0042] (2) Al synthesized with step (1) 2 Mo 3 o 12 The precursor is the matrix, and one or more of titanium dioxide, calcium titanate, strontium titanate, samarium sodium titanate, and strontium calcium titanate powder are used as additives, according to the molar ratio of precursor powder to additive powder (0.5~1) : The ratio of (0.1~0.6) weighs each raw material; Then, put into the ball mill...

Embodiment 1

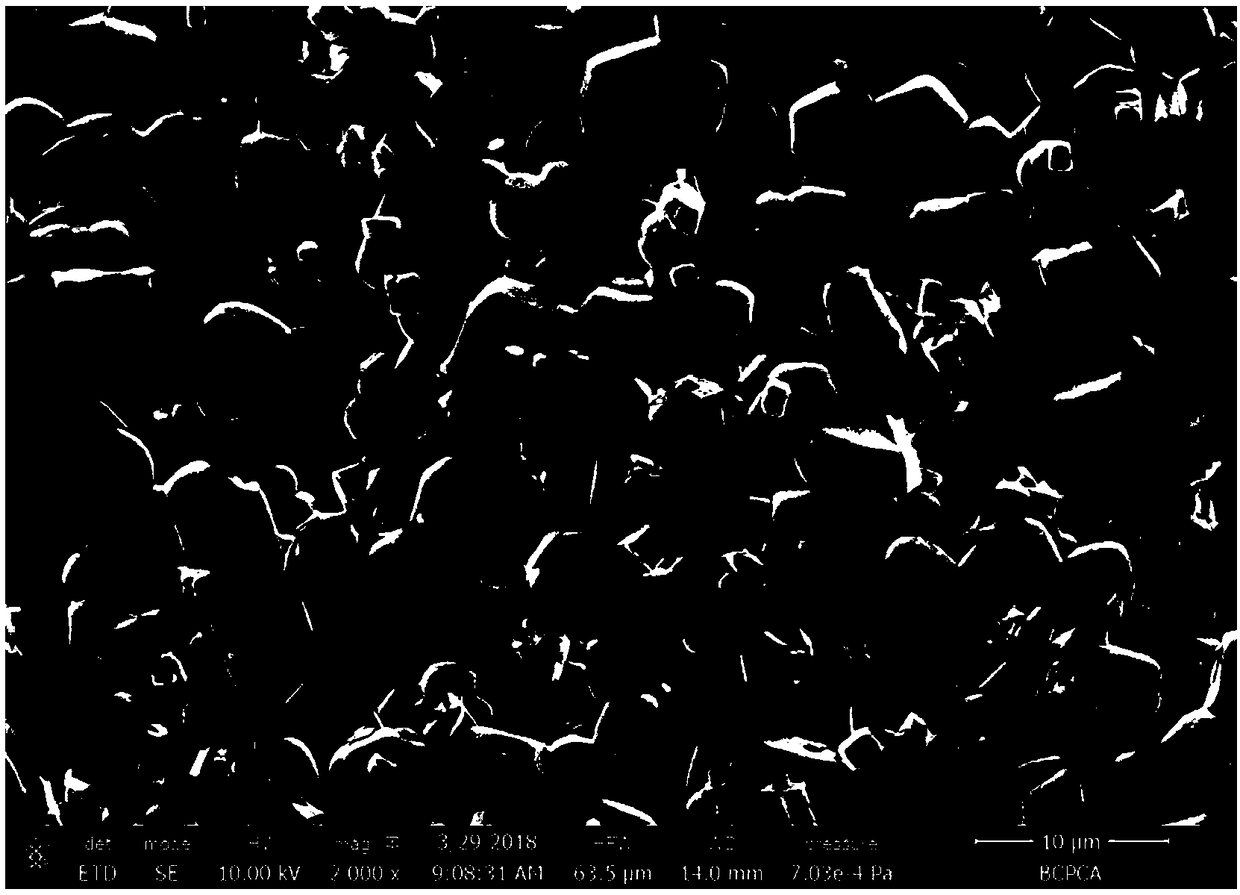

[0051] Example 1: First weigh 1 mole of analytically pure Al 2 o 3 and 3 moles of analytically pure MoO 3 powder, and then put them into the ball mill tank of the high-energy stirring ball mill, and weigh the high wear-resistant ZrO in the ratio of 2:10:5 by the mass ratio of mixed powder, balls, and solvent. 2 Add the balls and deionized water into the ball mill tank, and mix for 18 hours. After the ball milling is completed, the obtained slurry is moved to an oven, heated to 120° C., kept at a temperature of 4 hours, and dried in an atmospheric environment. Then, the dried powder cake was calcined in a muffle furnace with a heating rate of 15°C / min, a calcining temperature of 760°C, a heat preservation of 5 hours, and finally cooling with the furnace. Calcined and crushed Al 2 Mo 3 o 12 The powder of the precursor is put back into the ball mill tank of the clean high-energy stirring ball mill, and press Al2 Mo 3 o 12 Weigh analytically pure TiO at a ratio of 0.7:0.3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com