A kind of self-emulsifying water-based alkyd resin and self-emulsifying water-based alkyd paint and preparation method

A water-based alkyd resin, self-emulsifying technology, applied in coatings, polyester coatings, etc., can solve the problems of poor chemical resistance, viscosity drop, poor storage stability, etc., and achieve good water resistance and salt spray resistance, Effects of reducing usage consumption and solving water-solubility problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

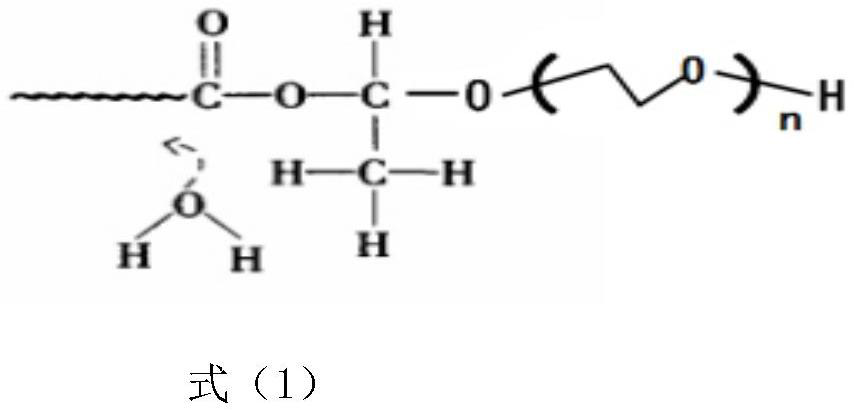

[0028] Embodiment 1 The preparation of self-emulsifying water-based alkyd resin

[0029] (1) Add 35g of linoleic acid, 20g of pentaerythritol, 28g of tetrahydrophthalic anhydride and 0.1g of hypophosphorous acid into the reaction kettle, and start to heat up after passing nitrogen gas for 10-20 minutes;

[0030] (2) It takes 1-3 hours to heat up the mixture in the reactor to 100-130°C, start the agitator and continue to heat up to 160-170°C;

[0031](3) Continue to heat up to 170-200°C at 10-15°C / hour, and keep warm for 2-3 hours until the material in the reactor is transparent;

[0032] (4) measure acid value, when acid value is 50~60mgKOH / g, add 8g secondary alcohol polyoxyethylene ether and carry out esterification;

[0033] (5) When the reaction is stopped and the temperature is lowered to 100-120°C, slowly add 21g of propylene glycol methyl ether dropwise, stir for 10-20min, and measure the acid value. When the acid value is less than 15mgKOH / g, cool down to obtain a sel...

Embodiment 2

[0035] Preparation of self-emulsifying waterborne alkyd resin

[0036] (1) Add 40g of linoleic acid, 20g of pentaerythritol, 25g of tetrahydrophthalic anhydride and 0.1g of benzenesulfonic acid into the reaction kettle, and start to heat up after passing nitrogen gas for 10-20min;

[0037] (2) It takes 1-3 hours to heat up the mixture in the reactor to 100-130°C, start the agitator and continue to heat up to 160-170°C;

[0038] (3) Continue to heat up to 170-200°C at 10-15°C / hour, and keep warm for 2-3 hours until the material in the reactor is transparent;

[0039] (4) measure acid value, when acid value is 50~60mgKOH / g, add 8g secondary alcohol polyoxyethylene ether and carry out esterification;

[0040] (5) When the reaction is stopped and the temperature is lowered to 100-120°C, slowly add 22g of propylene glycol methyl ether dropwise, stir for 10-20min, and measure the acid value. When the acid value is less than 15mgKOH / g, cool down to obtain a self-emulsifying water-ba...

Embodiment 3

[0042] Preparation of self-emulsifying waterborne alkyd resin

[0043] (1) Add 35g of linoleic acid, 21g of pentaerythritol, 30g of tetrahydrophthalic anhydride and 0.1g of benzenesulfonic acid into the reaction kettle, and start to heat up after passing nitrogen gas for 10 to 20 minutes;

[0044] (2) It takes 1-3 hours to heat up the mixture in the reactor to 100-130°C, start the agitator and continue to heat up to 160-170°C;

[0045] (3) Continue to heat up to 170-200°C at 10-15°C / hour, and keep warm for 2-3 hours until the material in the reactor is transparent;

[0046] (4) measure acid value, when acid value is 50~60mgKOH / g, add 8g secondary alcohol polyoxyethylene ether and carry out esterification;

[0047] (5) When the reaction is stopped and the temperature is lowered to 100-120°C, slowly add 21g of propylene glycol methyl ether dropwise, stir for 10-20min, and measure the acid value. When the acid value is less than 15mgKOH / g, cool down to obtain a self-emulsifying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com