Fabric with zirconium-based shield and weaving process of fabric

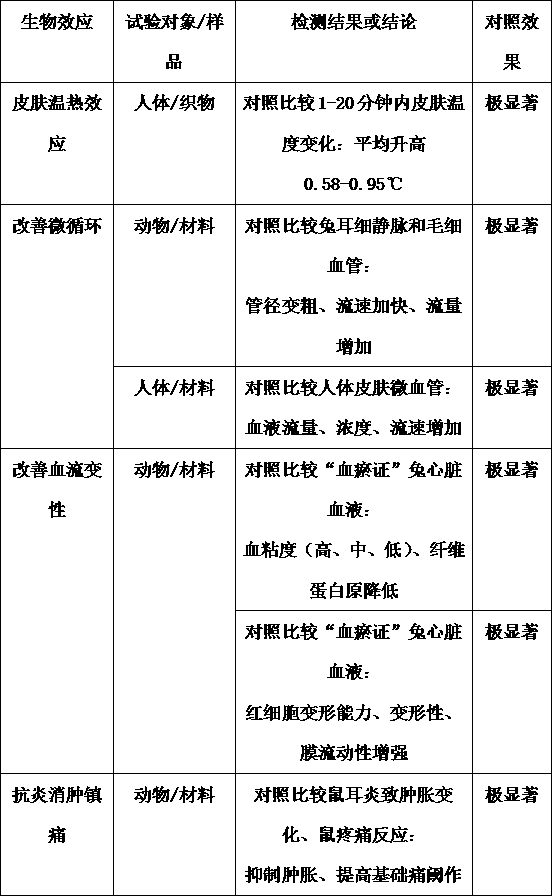

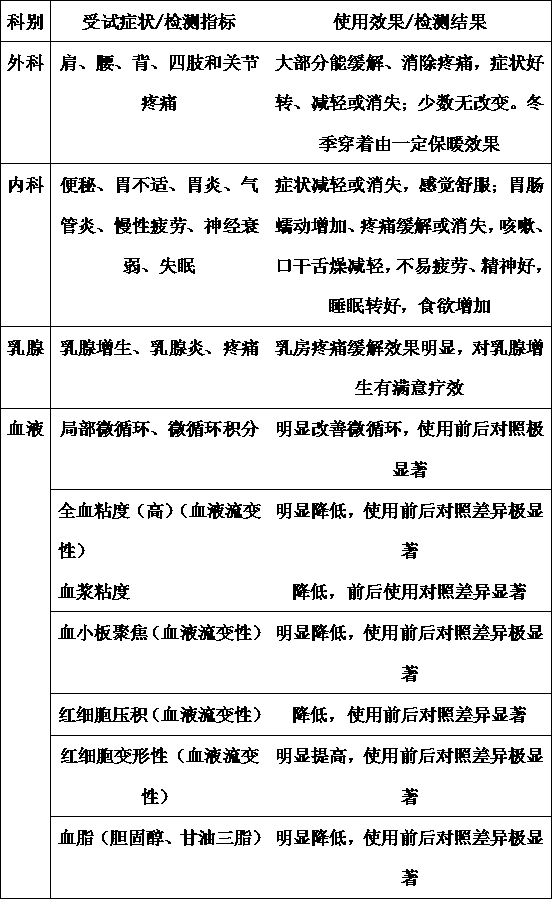

A zirconium-based shield and fabric technology, applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of poor zirconium nanometer effect and short service life, and achieve the goal of improving microcirculation, improving immunity, and promoting the recovery of inflammation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A fabric with a zirconium-based shield, the fabric is blended with cotton and zirconium fiber yarn, the blended weight ratio is 34% cotton and 66% zirconium fiber yarn, and the zirconium fiber yarn is polyester filament or polyester staple fiber.

[0023] A weaving process for fabrics with zirconium-based shields, the specific steps are as follows:

[0024] A, prepare zirconium fiber yarn:

[0025] a. Select nano zirconia;

[0026] b. Grinding the selected nano zirconia into powder through a jet mill, which is nano zirconia powder;

[0027] c. Blending the nano zirconium dioxide powder through polyester and slicing it into zirconium masterbatch;

[0028] D, nano zirconium dioxide powder, anionic surfactant, nitrate, tin tetrachloride are successively dissolved in water, and the mass concentration of preparation zirconium oxychloride is 5% impregnation salt solution containing zirconium;

[0029] e, immersing the fiber in a zirconium-containing impregnating salt solu...

Embodiment 2

[0033] A fabric with a zirconium-based shield, the fabric is blended with cotton and zirconium fiber yarn, the blended weight ratio is 56% cotton and 44% zirconium fiber yarn, and the zirconium fiber yarn is polyester filament or polyester staple fiber.

[0034] A weaving process for fabrics with zirconium-based shields, the specific steps are as follows:

[0035] A, prepare zirconium fiber yarn:

[0036] a. Select nano zirconia;

[0037] b. Grinding the selected nano zirconia into powder through a jet mill, which is nano zirconia powder;

[0038] c. Blending the nano zirconium dioxide powder through polyester and slicing it into zirconium masterbatch;

[0039] D, nano zirconium dioxide powder, anionic surfactant, nitrate, tin tetrachloride are dissolved in water successively, the mass concentration of preparation zirconium oxychloride is the dipping salt solution containing zirconium of 6%;

[0040] e, immersing the fiber in a zirconium-containing impregnating salt soluti...

Embodiment 3

[0044] A fabric with a zirconium-based shield, the fabric is blended with cotton and zirconium fiber yarn, the blended weight ratio is 78% cotton and 22% zirconium fiber yarn, and the zirconium fiber yarn is polyester filament or polyester staple fiber.

[0045] A weaving process for fabrics with zirconium-based shields, the specific steps are as follows:

[0046] A, prepare zirconium fiber yarn:

[0047] a. Select nano zirconia;

[0048] b. Grinding the selected nano zirconia into powder through a jet mill, which is nano zirconia powder;

[0049] c. Blending the nano zirconium dioxide powder through polyester and slicing it into zirconium masterbatch;

[0050] D, nano zirconium dioxide powder, anionic surfactant, nitrate, tin tetrachloride are dissolved in water successively, the mass concentration of preparation zirconium oxychloride is the impregnating salt solution containing zirconium of 7%;

[0051] e, immersing the fiber in a zirconium-containing impregnating salt s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com