Solar cell back electrode, solar cell and preparation method of solar cell back electrode

A technology for solar cells and back electrodes, applied in the field of solar cells, can solve the problems of holes, cracks, and large introductions in the film layer, and achieve the effects of improving high temperature tolerance, reducing residual stress, and good high temperature tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

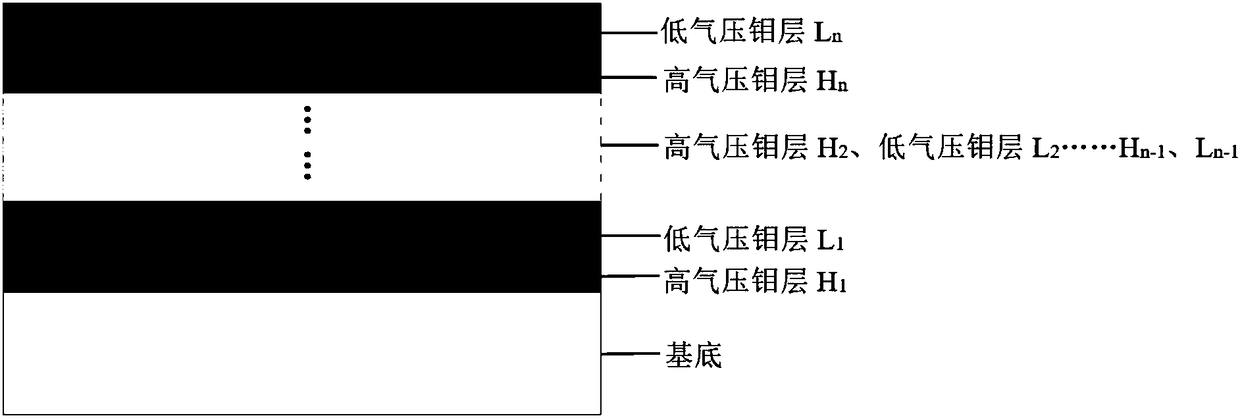

[0028] The preparation method of the back electrode of the solar cell provided by the present invention comprises adopting the magnetron sputtering method to sequentially and alternately deposit high-pressure molybdenum layers and low-pressure molybdenum layers on one side of the substrate as the bottom electrode, and the thickness of each high-pressure molybdenum layer is Each independently is 30-200nm, preferably each independently is 40-150nm, more preferably each independently is 50-100nm, the thickness of each low-pressure molybdenum layer is each independently 40-300nm, preferably each independently is 50-250nm , more preferably each independently is 100-200nm, the pressure of depositing each high pressure molybdenum layer is each independently 0.7-3.0Pa, preferably each independently is 1.0-2.5Pa, more preferably each independently is 1.0-2.0Pa, deposits The pressure of each low-pressure molybdenum layer is independently 0.01-0.5Pa, preferably independently 0.05-0.4Pa, m...

specific Embodiment approach

[0034] According to a specific embodiment of the present invention, the preparation method of the back electrode of the solar cell further includes, after the deposition of the high-pressure molybdenum layer and the low-pressure molybdenum layer, using the magnetron sputtering method on the outermost low-pressure molybdenum layer A surface molybdenum layer is deposited on the surface, and the pressure for depositing the surface molybdenum layer is 0.01-3.0Pa, preferably 0.05-1.5Pa, more preferably 0.1-1.0Pa. The specific structure of the solar battery back electrode formed in this way is high pressure molybdenum layer / low pressure molybdenum layer / ... / high pressure molybdenum layer / low pressure molybdenum layer / surface molybdenum layer. The thickness of the molybdenum layer on the surface is preferably 10-200 nm, more preferably 10-100 nm, further preferably 20-75 nm. The deposition rate of the molybdenum layer on the surface may be 5-30 nm / min, preferably 10-20 nm / min.

Embodiment approach

[0035] According to the present invention, in order to improve the adhesion of the bottom electrode on the surface of the substrate, preferably, the preparation method of the back electrode of the solar cell further includes, before depositing the high-pressure molybdenum layer and the low-pressure molybdenum layer, the surface of the substrate is first Pretreatment, the method of pretreatment includes cleaning the surface of the substrate, then putting it into a coating chamber to evacuate to below 5.0E-3Pa, and then baking at 100-200°C to remove water vapor. Wherein, the cleaning method may be, for example, at least one of alkali washing, alcohol washing, water washing and the like. According to a preferred embodiment of the present invention, the cleaning method includes ultrasonically cleaning the substrate in an alkaline cleaning solution for 10-30 minutes, taking out the substrate and rinsing it with deionized water to remove residual lye, and then Place the substrate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com