Direct drinking water treatment membrane containing graphene micro-sheet as well as preparation method thereof

A technology of graphene microchips and treatment membranes, applied in the direction of adsorption water/sewage treatment, permeation/dialysis water/sewage treatment, general water supply conservation, etc., can solve the problems of weakened adsorption effect and difficulty in retaining the specific surface area of graphene, etc., to achieve Guarantee the safety of drinking water, the effect of excellent adsorption and purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

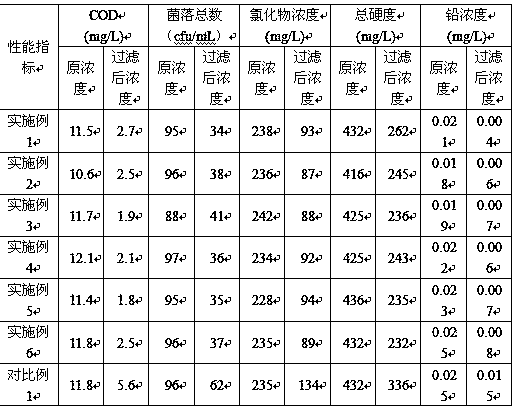

Examples

Embodiment 1

[0031] 26kg of m-phenylenediamine and 74kg of water are made into water phase solution, 34kg of trimesoyl chloride and 66kg of toluene are made into oil phase solution; then a porous ceramic substrate with a porosity of 66% and an average pore diameter of 120nm is laid on the platform Then immerse it in the water phase solution containing m-phenylenediamine, take it out after 13min, immerse it in the oil phase solution, take it out after the reaction is completed, remove the excess solvent, and get the treatment film in the initial state; coat the surface of the treatment film in the initial state Polyacrylamide adhesive, and then through the spray nozzle with a pore size of 30 μm, the graphene microflakes with 13 carbon layers and an average thickness of 22 nm are sprayed out at a spray pressure of 50 kg / cm, deposited on the coating surface, and the spraying process is repeated; A laser with a power of 33MW was used to rapidly heat and dry for 7s, and after solidification, a m...

Embodiment 2

[0036] 20kg of m-phenylenediamine and 80kg of water are made into water phase solution, 30kg of trimesoyl chloride and 70kg of xylene are made into oil phase solution; then a porous ceramic with a porosity of 60% and an average pore size of 50nm is laid on the platform Then immerse the substrate in the aqueous phase solution containing m-phenylenediamine, take it out after 10min, and immerse it in the oil phase solution, take it out after the reaction is completed, remove the excess solvent, and obtain the treatment film in the initial state; coat the surface of the treatment film in the initial state Cover with polyacrylamide adhesive, and then spray graphene microflakes with 10 carbon layers and an average thickness of 10nm through a nozzle with a pore size of 20 μm at a spray pressure of 30kg / cm, deposit on the coating surface, and repeat the spraying process ; Utilize a laser with a power of 20MW to quickly heat and dry for 10s, and obtain a direct drinking water treatment ...

Embodiment 3

[0039] 22kg of m-phenylenediamine and 78kg of water are made into water phase solution, 33kg of trimesoyl chloride and 67kg of trimethylbenzene are made into oil phase solution; then a porous ceramic with a porosity of 62% and an average pore size of 100nm is laid on the platform Then immerse the substrate in the water phase solution containing m-phenylenediamine, take it out after 11 minutes, immerse it in the oil phase solution, take it out after the reaction is completed, remove the excess solvent, and obtain the treatment film in the initial state; coat the surface of the treatment film in the initial state Cover with polyacrylamide adhesive, and then spray graphene microflakes with 11 carbon layers and an average thickness of 15nm through a nozzle with a pore size of 25 μm at a spray pressure of 40kg / cm, deposit on the coating surface, and repeat the spraying process ;Use a laser with a power of 25MW to quickly heat and dry for 9s, and obtain a direct drinking water treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com