Preparation method of oxygen-permeation-hydrogen permeation-methane partial oxidative dehydrogenation three-effect flat plate type membrane reactor and testing system thereof

An oxidative dehydrogenation, flat membrane technology, applied in chemical/physical/physical-chemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc., can solve the problem that product separation cannot be carried out simultaneously in the same reactor, etc. problem, to achieve the effect of promoting the movement of the product, preventing the deep oxidation of methane, and achieving separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

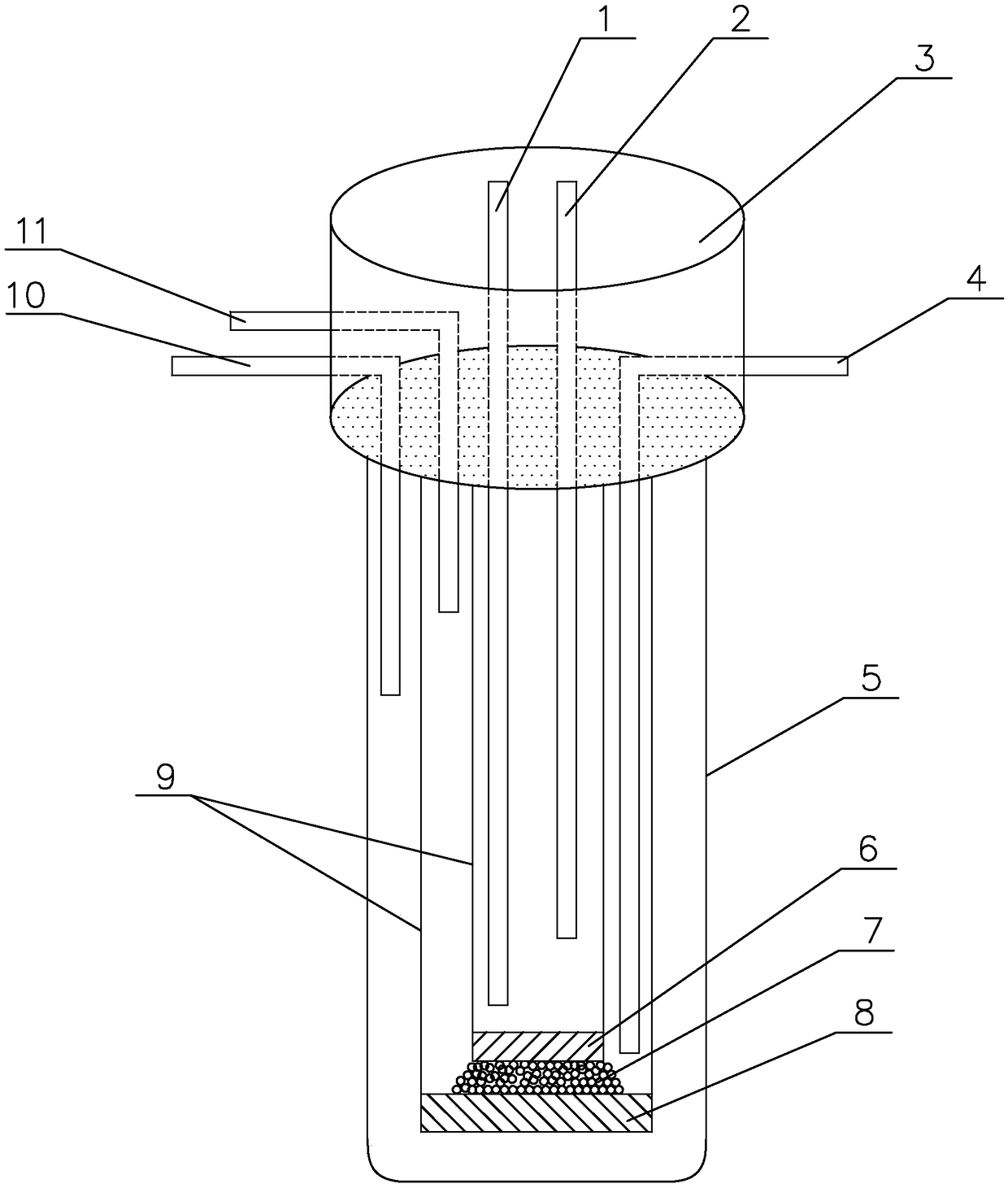

Embodiment 1

[0045] 10g La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3 (LSCF) ceramic powder and 10g SrCe 0.9 Y 0.1 o 3 (SCY) ceramic powders were added to two agate mortars, fully ground and passed through a 200-mesh sieve; the LSCF ceramic powders were pressed into a diameter of LSCF ceramic oxygen-permeable membrane body with a diameter of 12mm and a thickness of 1.0mm was pressed into a SCY ceramic hydrogen-permeable membrane body with a diameter of 15mm and a thickness of 1.0mm; then the LSCF ceramic oxygen-permeable membrane body was In the box-type high-temperature resistance furnace, the temperature was raised to 1350°C at a heating rate of 5°C / min, kept for 5 hours, and then cooled to 800°C at a cooling rate of 5°C / min, and then naturally cooled to room temperature, resulting in a diameter of 10.8mm and a thickness of 0.94 mm LSCF dense ceramic oxygen-permeable membrane; then the SCY ceramic hydrogen-permeable membrane body was heated to 1400°C at a heating rate of 5°C / min in a box-type h...

Embodiment 2

[0050] Using La 0.8 Ca 0.2 FeO 3 (LCF) ceramic powder and SrCe 0.9 Y 0.1 o 3 (SCY) ceramic powders were used to prepare LCF dense ceramic oxygen-permeable membranes and SCY dense ceramic hydrogen-permeable membranes, and the preparation process was the same as in Example 1. An LCF dense ceramic oxygen permeable membrane with a diameter of 10.9 mm and a thickness of 0.85 mm and an SCY dense ceramic hydrogen permeable membrane with a diameter of 14.0 mm and a thickness of 0.96 mm were obtained.

[0051] After corroding and roughening one surface of SCY dense ceramic hydrogen permeable membrane with concentrated hydrochloric acid, 0.8g of the metal nickel catalyst in Example 1 is supported on the surface, and the diameter occupied by the supported metal nickel catalyst is 11 mm, and then the LCF is dense The ceramic oxygen permeable membrane and the SCY dense ceramic hydrogen permeable membrane were respectively packaged at the bottom of corundum tubes suitable for their res...

Embodiment 3

[0054] Using Ce 0.8 SM 0.2 o 1.9 (SDC) ceramic powder and SrCe 0.9 Y 0.1 o 3 (SCY) ceramic powder was used to prepare SDC dense ceramic oxygen permeable membrane and SCY dense ceramic hydrogen permeable membrane respectively, and the preparation process was the same as in Example 1. An SDC dense ceramic oxygen permeable membrane with a diameter of 11.0 mm and a thickness of 0.96 mm and an SCY dense ceramic hydrogen permeable membrane with a diameter of 13.8 mm and a thickness of 0.98 mm were obtained.

[0055] The SDC ceramic powder and SCY ceramic powder with a mass ratio of 1:1 were ball milled on a fast ball mill for 2 hours, calcined at 900°C for 2 hours, ball milled for 2 minutes, and sieved with a 150-mesh sieve to obtain a uniformly mixed powder by physical mixing method. as a catalyst carrier. Mix the catalyst carrier with a mass ratio of 4:6 and the nickel oxide powder on a ball mill, calcinate at 900°C for 2 hours, ball mill for 2 minutes, and sieve with a 150-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com