A continuous macroscopic graphene nanoribbon fiber and preparation method thereof

A graphene nanoribbon and fiber technology, which is applied in the direction of graphene, nanocarbon, fiber chemical characteristics, etc., can solve the problem of unrealized macroscopic graphene nanoribbon fiber, and achieve high strength, easy regulation and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

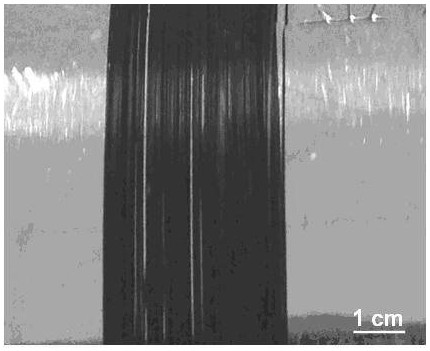

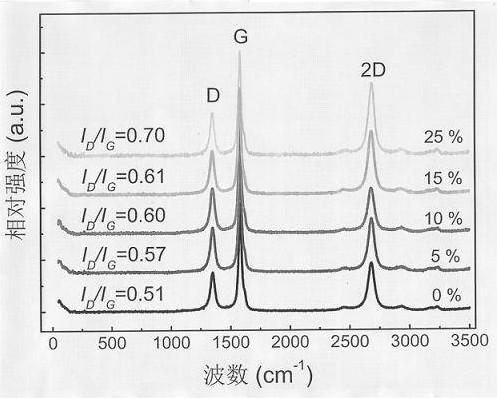

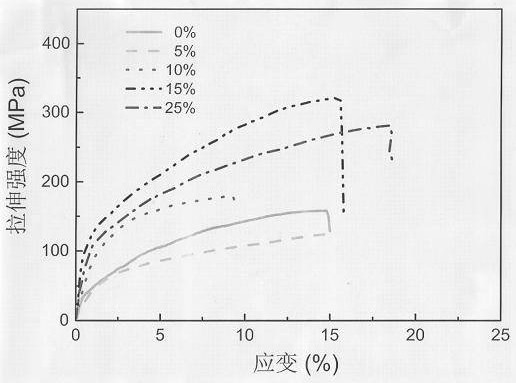

Embodiment 1

[0020] Weigh and mix ethanol, ferrocene, and thiophene according to the mass ratio of 150:3:1, then add deionized water, and mix well by ultrasonication for 30 minutes to obtain a uniform reaction liquid, wherein the mass fraction of water in the reaction liquid is 25%. The reaction liquid was injected into the tubular reaction furnace with 1000 sccm hydrogen carrier gas flow at a rate of 8 mL / h with a micro-syringe pump. The temperature in the reaction zone was 1150 °C. Graphene nanoribbons grew and assembled in the reaction zone to form filamentous aggregates. , moved to the end of the reaction furnace driven by the hydrogen flow, the graphene nanoribbon aggregates were pulled out from the reaction furnace, densely shrunk by water, and wound on the spinning shaft at a spinning speed of 4 m / min to obtain a continuous macroscopic Graphene nanoribbon fibers.

[0021] The continuous macroscopic graphene nanoribbon fibers prepared by the above steps and conditions can reach hundr...

Embodiment 2

[0023] Change the content of deionized water to 15%, and other experimental processes and conditions are the same as in Example 1.

[0024] Specifically: weigh and mix ethanol, ferrocene, and thiophene according to the mass ratio of 150:3:1, then add deionized water, and mix evenly by ultrasonication for 30 minutes to obtain a uniform reaction solution. The mass fraction of water in the reaction solution is 15%. The reaction liquid was injected into the tubular reaction furnace with 1000 sccm hydrogen carrier gas flow at a rate of 8 mL / h with a micro-syringe pump. The temperature in the reaction zone was 1150 °C. Graphene nanoribbons grew and assembled in the reaction zone to form filamentous aggregates. , moved to the end of the reaction furnace driven by the hydrogen flow, the graphene nanoribbon aggregates were pulled out from the reaction furnace, densely shrunk by water, and wound on the spinning shaft at a spinning speed of 4 m / min to obtain a continuous macroscopic Gra...

Embodiment 3

[0027] Change the content of deionized water to 10%, and other experimental procedures and conditions are the same as in Example 1.

[0028] Specifically: weigh and mix ethanol, ferrocene, and thiophene according to the mass ratio of 150:3:1, then add deionized water, and mix evenly by ultrasonication for 30 minutes to obtain a uniform reaction solution. The mass fraction of water in the reaction solution is 10%. The reaction liquid was injected into the tubular reaction furnace with 1000 sccm hydrogen carrier gas flow at a rate of 8 mL / h using a micro-syringe pump. The temperature in the reaction zone was 1150 °C. The reaction liquid cracked and grew in the reaction zone and assembled to form cylindrical aggregates. Driven by the hydrogen flow, it moves to the end of the reactor, pulls the aggregates out of the reactor, shrinks them densely with water, and winds them on the spinning shaft at a spinning speed of 4 m / min to produce a continuous fiber product.

[0029]The produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com