Ultraviolet-resistant corrosion-resistant auto film

An anti-ultraviolet and car film technology, applied in the field of car film, can solve the problems of poor film transparency, high price, complicated process, etc., and achieve the effect of excellent mechanical properties, good anti-oxidation performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

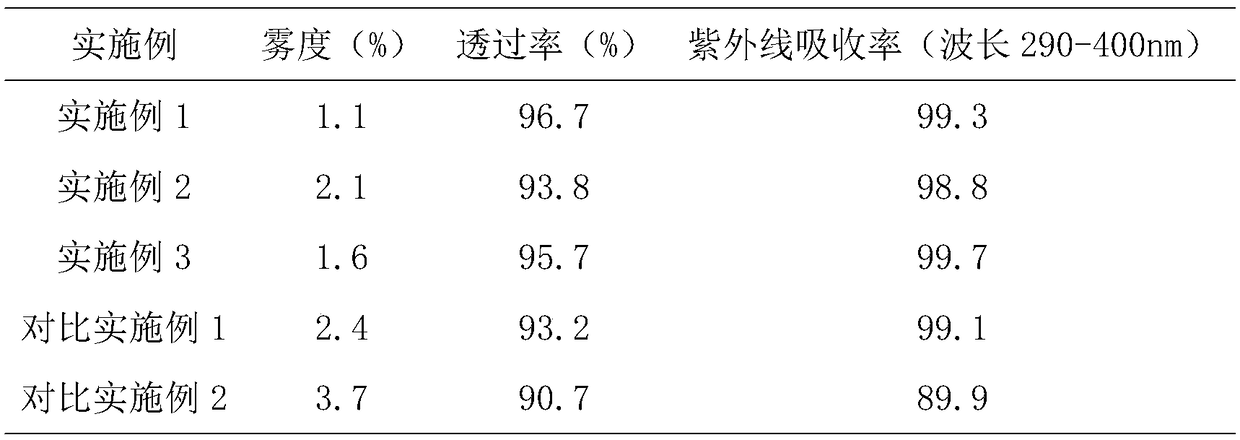

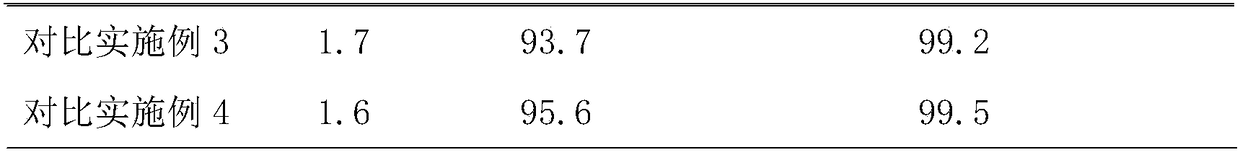

Examples

Embodiment 1

[0033] Embodiment 1: a kind of anti-ultraviolet, anti-corrosion car film, the composition that it contains and preparation method are as follows:

[0034] 30 parts of polymethyl methacrylate, 10 parts of polydioctyl phthalate, 3 parts of propylene glycol p-toluate, 4 parts of tert-butyldimethylchlorosilane, 3 parts of phosphate emulsifier, low methyl ether 5 parts of melamine formaldehyde resin, 8 parts of diisooctyl phthalate, 5 parts of sodium metabisulfite, 5 parts of molybdenum dialkyldithiocarbamate, and 10 parts of anti-ultraviolet nanocomposite material.

[0035]A: The preparation method of the anti-ultraviolet nanocomposite material is as follows: disperse 11 parts of nanometer antimony trioxide into isopropanol, add 6 parts of nanometer ceria, and stir to obtain the first mixed solution; Acetone is added dropwise into the solution, placed after sealed and stirred, centrifuged, cleaned and dried to obtain antimony trioxide coated with nano cerium oxide; the antimony tr...

Embodiment 2

[0045] Embodiment 2: a kind of anti-ultraviolet, anti-corrosion car film, the composition that it contains and preparation method are as follows:

[0046] 50 parts of polymethyl methacrylate, 20 parts of polydioctyl phthalate, 12 parts of propylene glycol p-toluate, 13 parts of tert-butyldimethylchlorosilane, 14 parts of phosphate emulsifier, low methyl ether 14 parts of melamine formaldehyde resin, 15 parts of diisooctyl phthalate, 15 parts of sodium metabisulfite, 15 parts of molybdenum dialkyldithiocarbamate, and 15 parts of anti-ultraviolet nanocomposite.

[0047] A: The preparation method of the anti-ultraviolet nanocomposite material is: disperse 14 parts of nano antimony trioxide in isopropanol, add 8 parts of nano cerium oxide, and stir to obtain the first mixed solution; drop into the first mixed solution Add acetone, place after sealing and stirring, centrifuge, wash and dry to obtain antimony trioxide coated with nano cerium oxide; disperse the antimony trioxide coa...

Embodiment 3

[0057] Embodiment 3: a kind of anti-ultraviolet, anti-corrosion car film, the composition that it contains and preparation method are as follows:

[0058] 40 parts of polymethyl methacrylate, 15 parts of polydioctyl phthalate, 7.5 parts of propylene glycol p-toluate, 8.5 parts of tert-butyldimethylchlorosilane, 8.5 parts of phosphate emulsifier, low methyl ether 9.5 parts of melamine formaldehyde resin, 11.5 parts of diisooctyl phthalate, 10 parts of sodium metabisulfite, 10 parts of molybdenum dialkyldithiocarbamate, and 12.5 parts of anti-ultraviolet nanocomposite materials.

[0059] A: The preparation method of the anti-ultraviolet nanocomposite material is: 12.5 parts of nanometer antimony trioxide are dispersed in isopropanol, 7 parts of nanometer ceria are added, and the first mixed solution is obtained after stirring; drop into the first mixed solution Add acetone, place after sealing and stirring, centrifuge, wash and dry to obtain antimony trioxide coated with nano ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com