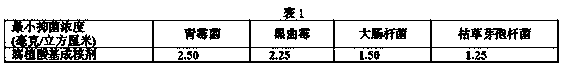

Preparation method and application of humin acid based poly (lactic acid) crystallization nucleating agent and material

A crystallization nucleating agent, polylactic acid technology, applied in the field of polylactic acid polymer materials, can solve the problems of low heat resistance, poor toughness, low polylactic acid crystallinity, etc., to achieve degradation performance and heat resistance expansion, excellent mechanics The effect of high performance and crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The polylactic acid crystallization nucleating agent based on humic acid, raw material comprises humic acid, carbonyldiimidazole, hydrochloric acid, pyridine and amines, the mass ratio of humic acid, carbonyldiimidazole and amines is 1 to 10:1 to 5: 1 to 10, the amount of hydrochloric acid added is 0.5% to 5% of the mass of humic acid, and the amount of pyridine added is 0.5% to 5% of the mass of humic acid.

Embodiment 2

[0031] Embodiment 2: the polylactic acid crystallization nucleating agent based on humic acid, raw material comprises humic acid, carbonyldiimidazole, hydrochloric acid, pyridine and amines, the mass ratio of humic acid, carbonyldiimidazole and amines is 1 or 10:1 or 5:1 or 10, the amount of hydrochloric acid added is 0.5% or 5% of the mass of humic acid, and the amount of pyridine added is 0.5% or 5% of the mass of humic acid.

Embodiment 3

[0032] Embodiment 3: the polylactic acid crystallization nucleating agent based on humic acid described in the foregoing examples is obtained by the following method: the first step, after dissolving the required amount of carbonyldiimidazole in tetrahydrofuran, obtains carbonyldiimidazole tetrahydrofuran solution; After adding the required amount of humic acid in the diimidazole tetrahydrofuran solution, the intermediate product is obtained; the second step is to add the required amount of hydrochloric acid and pyridine to the intermediate product, and then add the required amount of amines to stir the reaction to obtain the reaction product; the third The first step is to add distilled water to the reaction product for ultrasonic oscillation, and then filter and dry to obtain a solid product; the fourth step is to add the solid product to an organic solvent for ultrasonic oscillation to obtain a mixture, and the mixture is filtered and vacuum-dried to obtain Humic acid based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com